- 1 -

1.Cautionary instructions in handling the assy

(Safety instructions)

Optical pickup

The laser beam used in the pickup is classified as "class 2". Exposing

your eyes or skin to the beam is harmful. Take care not to do so.

(Caution against static electricity and leakage voltage)

Ground securely the work tables, tools, fixtures, soldering irons

(including those made of ceramic) and measuring instruments used

in the production lines and inspection departments that handle

loaders. The workers shall also be grounded.

(Cautionary instructions in handling)

Do not touch the object lens when handling a loader, or the lens will

be stained, resulting in inadequate playability.

There is no power supply protection circuit provided for this product

or adjustment/inspection device. Short-circuiting may lead to fire or

damage.

Take care so as to protect from exposure to water, the entry of

metallic pieces or dew condensation.

In particular, a strong magnet adjacent to the pickup will not only

get inoperative but can damage the pickup if a small metallic piece,

such as a screw or swarm, enters.

The loader edge can cause injury if inadvertently handled.

Do not touch a rotating disk, or injury may result.

This product is a precision device. Handle carefully.

A shock or dropping will cause misalignment or destruction. If it

should occur, refer to clause 2.

This product is so designed as to endure an initial shock equivalent

to a drop from a height of approx. 90 cm under the packed condition.

After the initial shock, the resistivity will still remain at a level of 50

to 60 G, but the mechanical robustness will weaken.

Do not place in a dusty location.

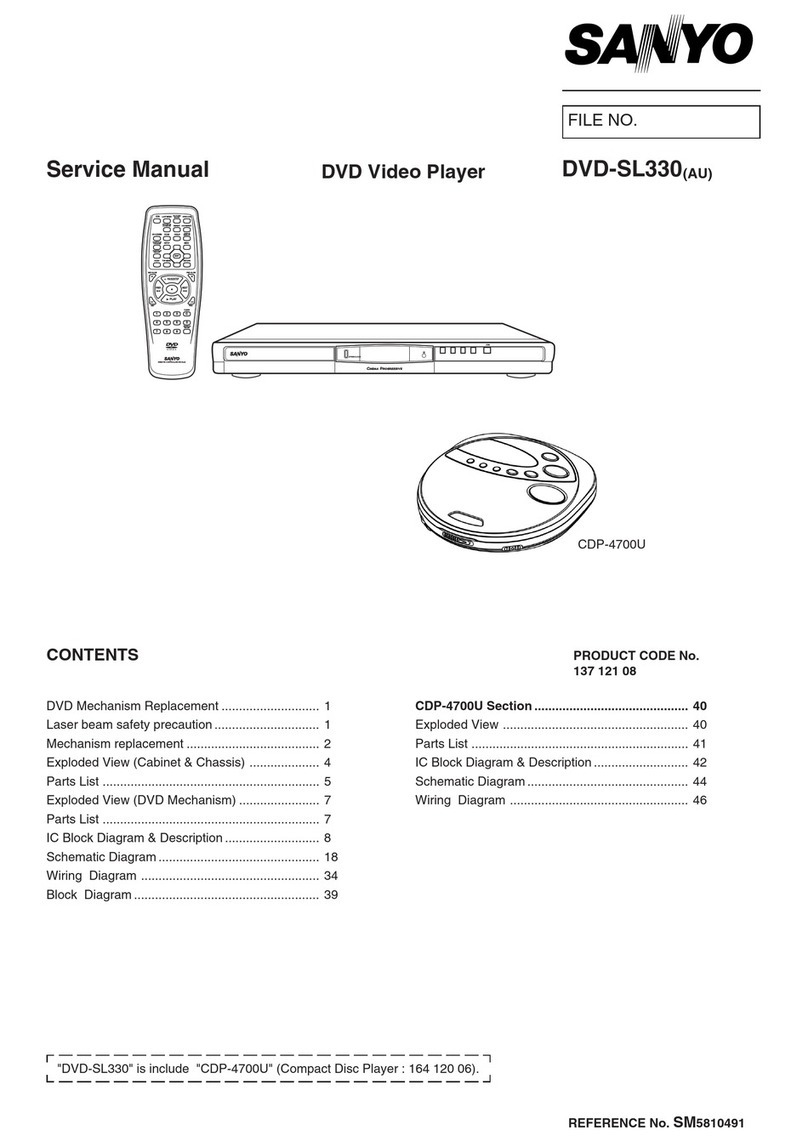

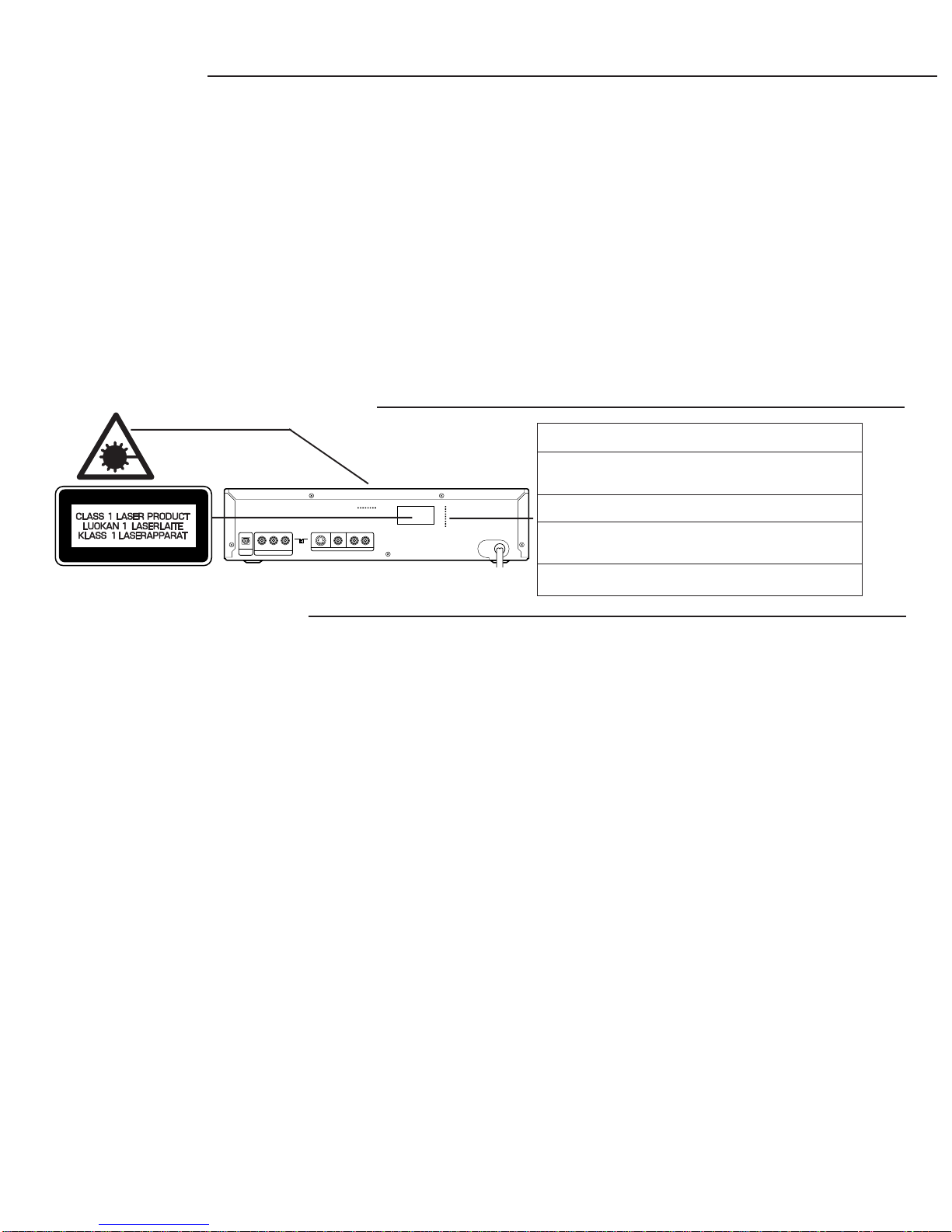

LASER BEAM SAFETY PRECAUTION

MECHANISM REPLACEMENT The entry and deposition of dirt into or on the pickup lens or moving

section will cause malfunction or degradation.

(Connectors)

Do not connect or disconnect while power is on.

Connecting or disconnecting signal wires or the main power cord

when the power is on may destruct the unit or fixture.

When connecting, push all the way in securely.

An insufficient insertion may cause a bad contact, leading to an

erroneous operation.

Do not connect or disconnect roughly by an excessively strong force,

or a broken wire or bad contact may result.

Semiconductors are connected. Do not touch connector terminals

directly.

If the worker is grounded, there is nothing to worry about static

electricity, but the rust on the connector terminal surface caused by

the touch may result in bad contact.

(Power source)

The power source need be good in quality (free from instantaneous

interruptions or noises).

A low quality power source may well cause malfunction.

(Storage)

Do not place or store in a dusty place or a place where dew

condensation is possible.

The entry and deposition of dirt or dust into or on the pickup lens or

moving section will cause malfunction or degradation.

Also, dew condensation causes rust;the rust penetrate into the

precision part of a pickup, causing malfunction, or degrading the

optical quality of the internal lens and reflector, which also leads to

malfunction.

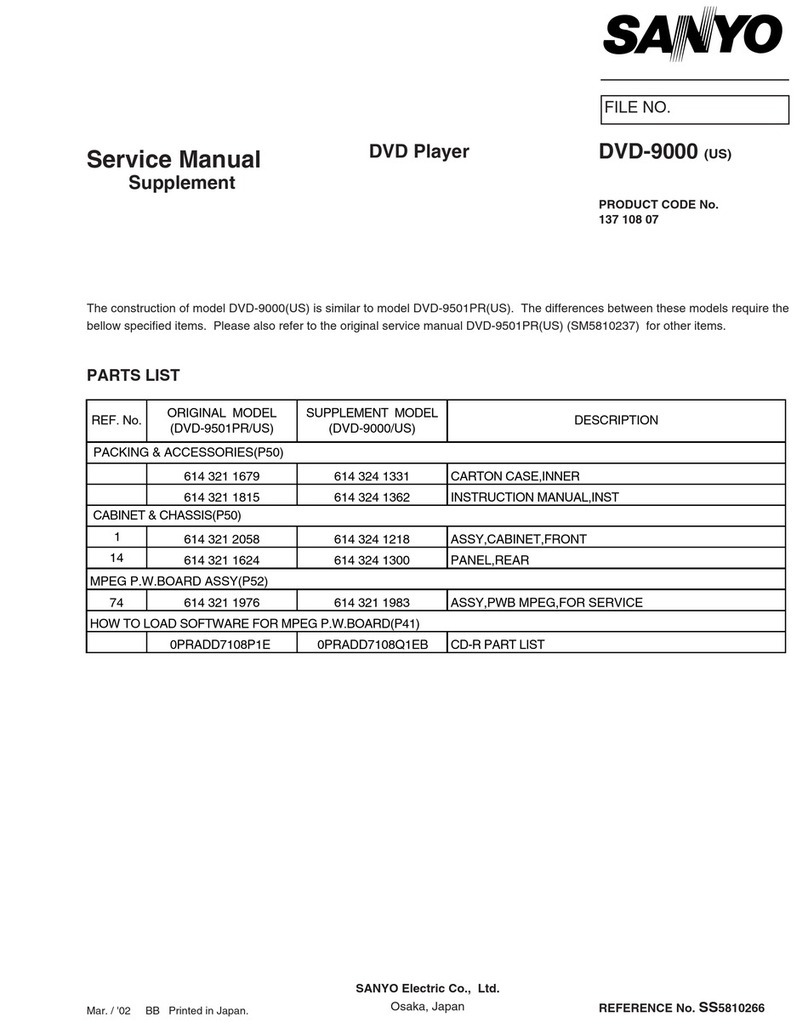

SPECIFICATIONS

Type ........................................ DVD player

Signal format ........................... NTSC or PAL color

Laser ....................................... Semiconductor laser,

wavelength 650nm

1 mW(DVD) , 0.5mW(CD)

Frequency range..................... 4 Hz to 44 kHz(DVD fs : 96kHz)

(digital audio)

Signal to noise ratio ................ More than 105 dB

Harmonic distortion ................. 0.003 %

(digital audio)

Wow and flutter ....................... Below measurable level

DIGITAL OUTPUT

COMPONENT VIDEO OUT

Y.............................................1.0V

C , C .....................................0.7V

S-VIDEO OUT

Y.............................................1.0V

C.............................................0.286V

VIDEO OUT .................................1.0V

AUDIO OUT .................................1.2V rms

Power requirements.....................AC 110 - 240V , 50/60Hz

Power consumption .....................16 Watts

Dimensions (W x H x D)...............Approx. 360 x 87 x 282 mm

Weight ..........................................Approx. 2.8kg

Specifications subject to change without notice.

p-p (75 ohm)

p-p (75 ohm)

p-p (75 ohm)

p-p (75 ohm)

p-p (75 ohm)

B R

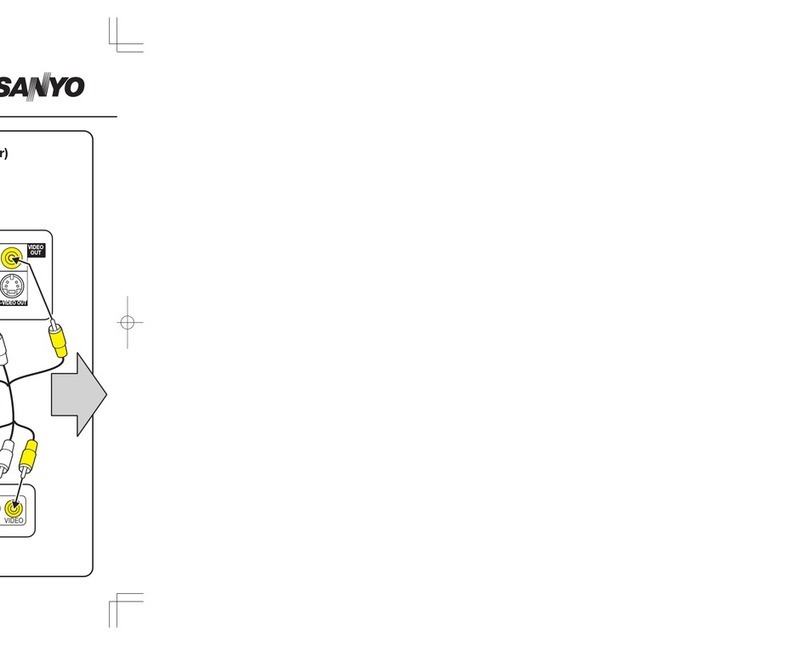

S-VIDEO OUT

DIGITAL

OUT

RL

OPT. VIDEO OUT AUDIO OUT

COMPONENT VIDEO OUT

YC

B

C

R

TV SYSTEM

PAL NTSC

CAUTION – INVISIBLE LASER RADIATION WHEN OPEN AND

INTERLOCKS DEFEATED. AVOID EXPOSURE TO BEAM.

ADVARSEL – USYNLIG LASER STRÅLING VED ÅBNING, NÅR

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION, UNDGÅ UDS ÆTTELSE

FOR STRÅLING.

VARNING – OSYNLIG LASER STRÅLNING NÄR DENNA DEL ÄR ÖPPNAD

OCH SPÄRR ÄR URKOPPLAD. STRÅLEN ÄR FARLIG.

VORSICHT – UNSICHTBARE LASERSTRAHLUNG TRITT AUS, WENN

DECKEL GEÖFFNET UND WENN SICHERHEITSVERRIEGELUNG

ÜBERBRÜCKT IST. NICHT, DEM STRAHL AUSSETZEN.

VARO – AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA

NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

(AU)