.- U

4ANDLING THE PICKUP

b.

,’,

. . .

. . .

1. Shipping and storage cautions

a.

b.

The pickup must be stored in aconductive bag

until immediately prior to its use.

Do not drop it or subject it to impacts.

c.

2.a.

d.

-.— .- .

Repair cautions . .. .. . .

When handling the pickup, be careful not to give it

undue force or shock by your hands. Otherwise the

pickup may malfunction or the PCB may be cracked.

The pickup which has been minutely adjusted before

shipment as one part. Never touch and move the

adjusting points and setscrews of the pickup unless

otherwise described in the item of adjustment to

avoid damage.

BEFORE REPAIRING THE CD PLAYER (CD)—

1.

a.

b.

Astrong magnet is used in the pickup.

Do not bring amagnet or other magnetized object

near to it.

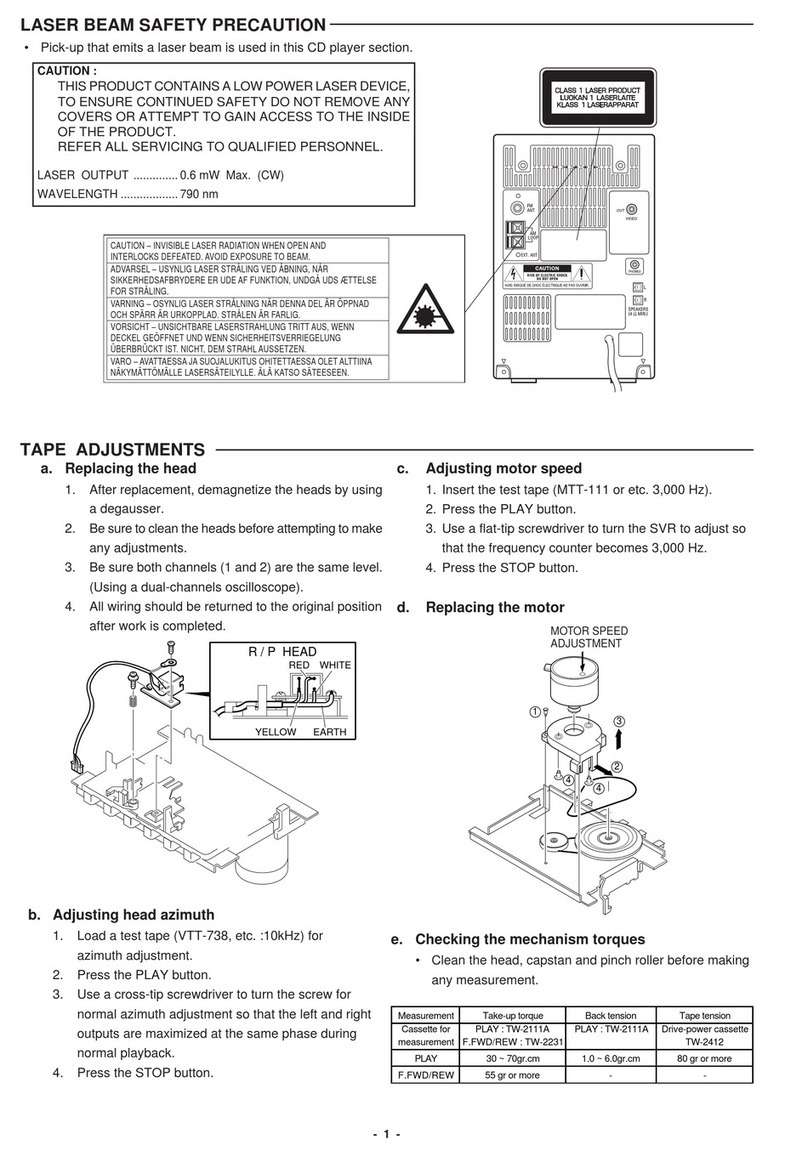

Cleaning the lens

*If dust gets on the lens, clean it away by using an

air brush such as used for acamera lens.

●The lens is held in place by aspring.

If the center of the lens is dirty, carefully clean” it

using cotton swab moistened with isopropylalcohol.

Since special coating is made on the surface of the

lens which is made of plastics, do not use other

kind of alcohol and cleaning fluid to prevent

damage to the lens. Also, be careful not to bend

the lens spring when cleaning. .. ...

.:..

.......

.,.

Preparations

Many ICS, LSI and the Pickup (laser diode) are

used in the compact disc player. These

components are sensitive to static electricity, and

might be damaged by static electricity or high

voltage, so particular care should be taken

regarding this point.

Many precision components and the lens are used in

the pickup.

Never attempt to make repairs, or to store parts,

where the temperature or humidity is high, where

magnetism is strong, or where there is much dust.

2. Notes regarding repairs

a. Be sure to first disconnect the power plug before

attempting to replace any component.

b. All tools, instruments, etc., used for measuring must

be grounded.

Grounding can be accomplished by using a

conductive metal sheet on the work bench.

c. To prevent AV leakage of the soldering iron, ground

its metal part.

d. Repair personnel must be grounded.

!EFORE USE OR TRANSPORTATION

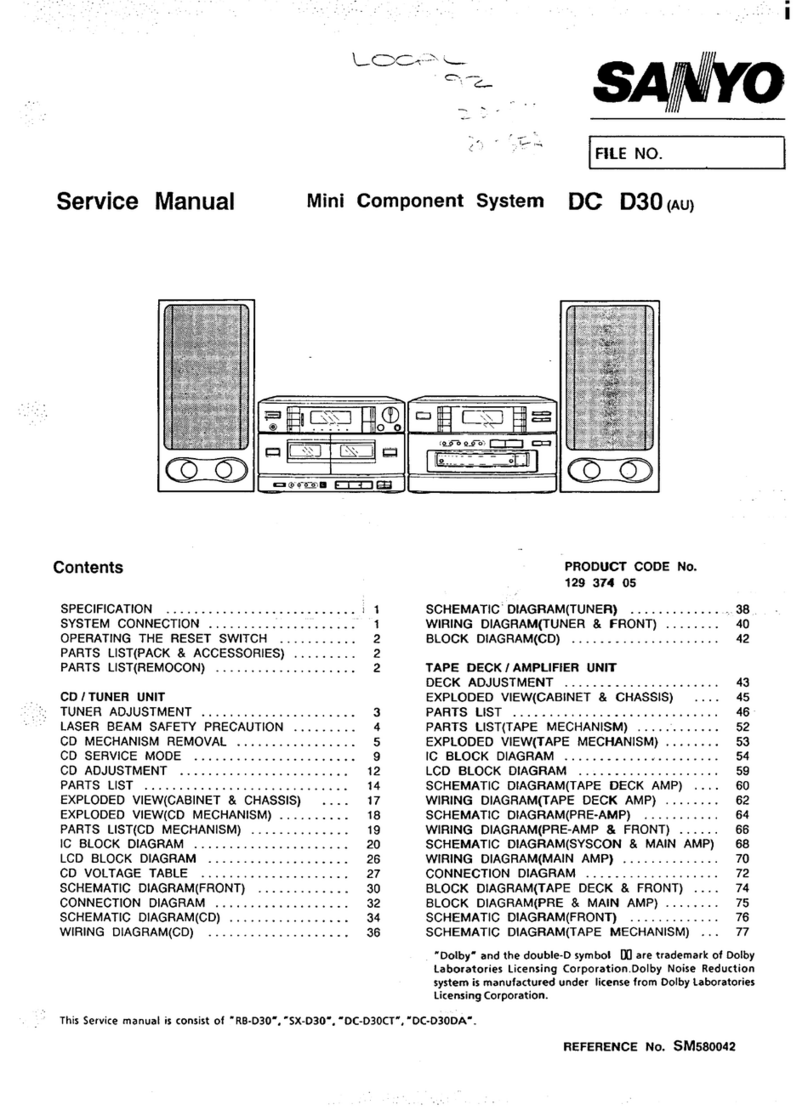

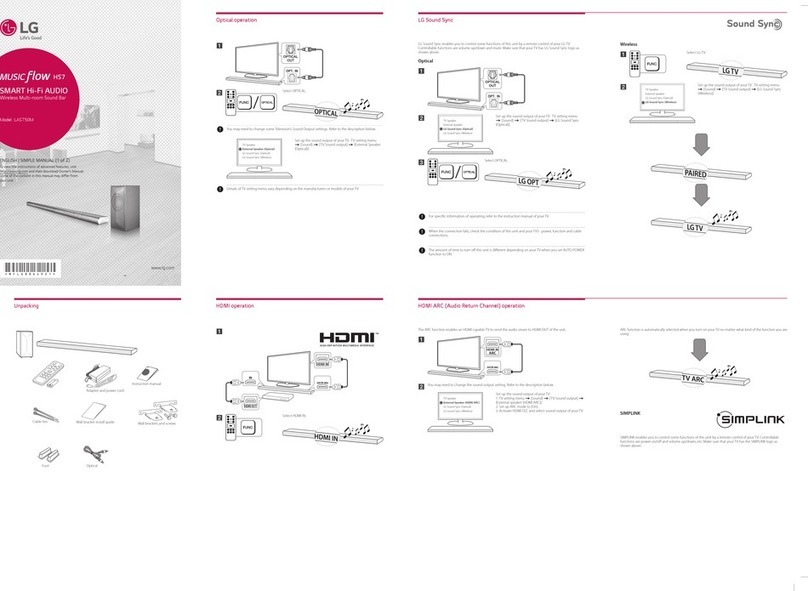

Before use

1. Carefully unpack the unit 3. Remove the sheet and tape which secures the

2. Remove all packing material from around the unit. carousel. ,..

4. Attach the dust Cover.

●-1- -.