F7YLV

1: An isolation transformer should be connected in the

power line between the receiver and the AC line

when a service is performed on the primary of the

converter transformer of the set.

2: Comply with all caution and safety-related notes

provided on the cabinet back, inside the cabinet, on

the chassis or the picture tube.

3: When replacing a chassis in the cabinet, always be

certain that all the protective devices are installed

properly, such as, control knobs, adjustment covers

or shields, barriers, isolation resistor-capacitor

networks etc. Before returning any television to the

customer, the service technician must be sure that

it is completely safe to operate without danger of

electrical shock.

-2-

SAFETY PRECAUTION

X-RADIATION PRECAUTION

The primary source of X-RADIATION in the television receiver is the picture tube. The picture tube is specially

constructed to limit X-RADIATION emissions. For continued X-RADIATION protection, the replacement tube must

be the same type as the original including suffix letter. Excessive high voltage may produce potentially hazardous

X-RADIATION. To avoid such hazards, the high voltage must be maintained within specified limit. Refer to this

service manual, high voltage adjustment for specific high voltage limit. If high voltage exceeds specified limits,

take necessary corrective action. Carefully follow the instructions for +B1 volt power supply adjustment, and high

voltage adjustment to maintain the high voltage within the specified limits.

PRODUCT SAFETY NOTICE

SPECIFICATIONS

Product safety should be considered when a component replacement is made in any area of a receiver.

Components indicated by mark in the parts list and the schematic diagram designate components in which

safety can be of special significance. It is particularly recommended that only parts designated on the parts list in

this manual be used for component replacement designated by mark . No deviations from resistance wattage or

voltage ratings may be made for replacement items designated by mark .

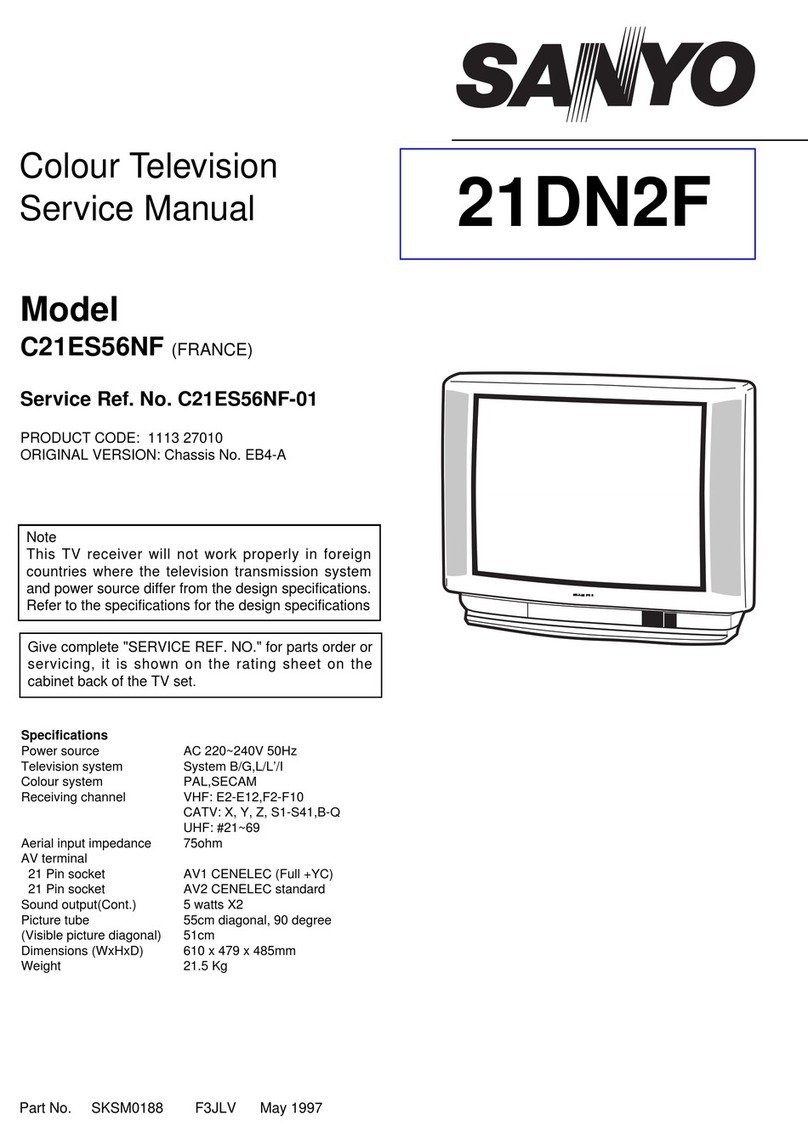

Power source AC 220~240V, 50Hz

Television system System B/G, D/K, I, L/L’

Colour system PAL/SECAM/NTSC4.43 on air

NTSC3.58 in AV mode

Channel coverage VHF: E2-E12, A-H, H1, H2, F2-F10, R1-R12

UHF: 21-69, F21-F69

CATV: X, Y, Z, Z+1, Z+2, S1-S41, B-Q

Aerial input impedance 75ohm

AV terminal

21-pin terminals AV1: CENELEC Standard with RGB

AV2: CENELEC Standard with S-inputs

AV3: CENELEC Standard

Front AV terminals AV3: RCA Terminal, Video and Audio(L/R) Input

Sound output Main L/R 10.0 x 2

(Continuous)(watts)

Picture tubes(inches) 32

Dimensions(WxHxD mm) 876 x 584 x 556

Weight (kg) 50kg