Sanyo VHR-1110 Series User manual

Other Sanyo VCR System manuals

Sanyo

Sanyo VHR-5300 User manual

Sanyo

Sanyo TLS-4960 User manual

Sanyo

Sanyo VHR-VX700 User manual

Sanyo

Sanyo VHR-870 User manual

Sanyo

Sanyo VHR-420 User manual

Sanyo

Sanyo VHR-150 User manual

Sanyo

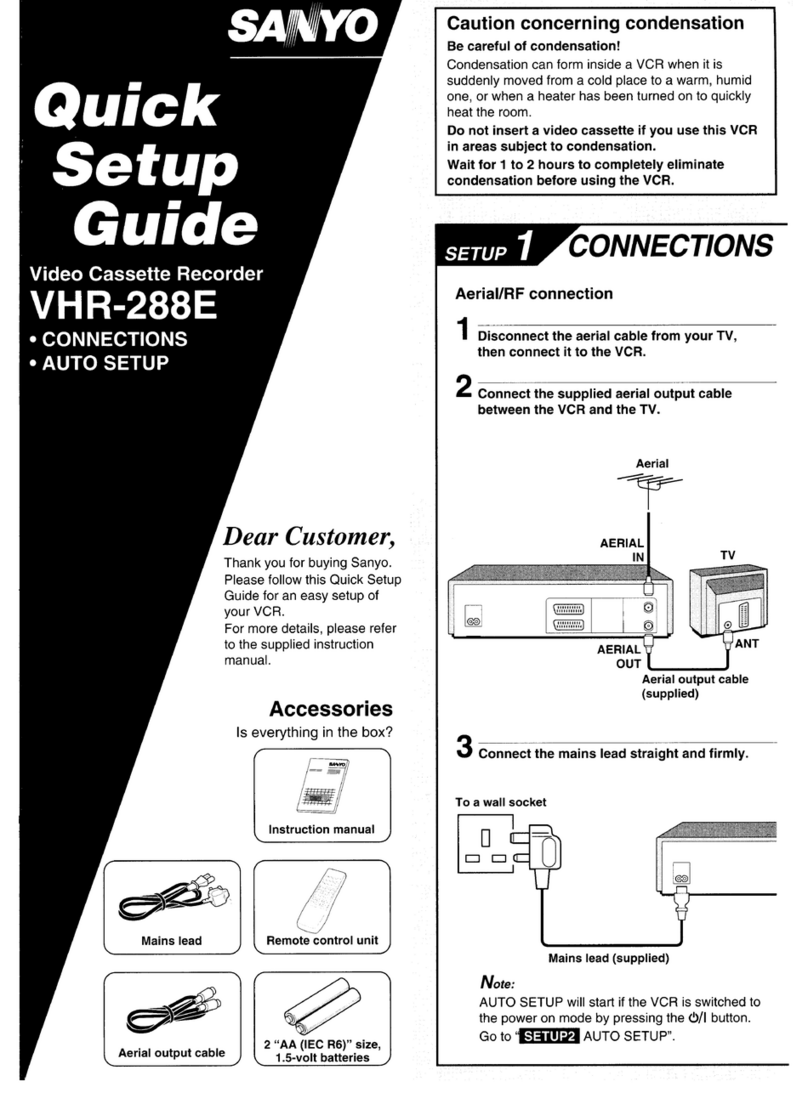

Sanyo VHR-288E User manual

Sanyo

Sanyo SRC-850 User manual

Sanyo

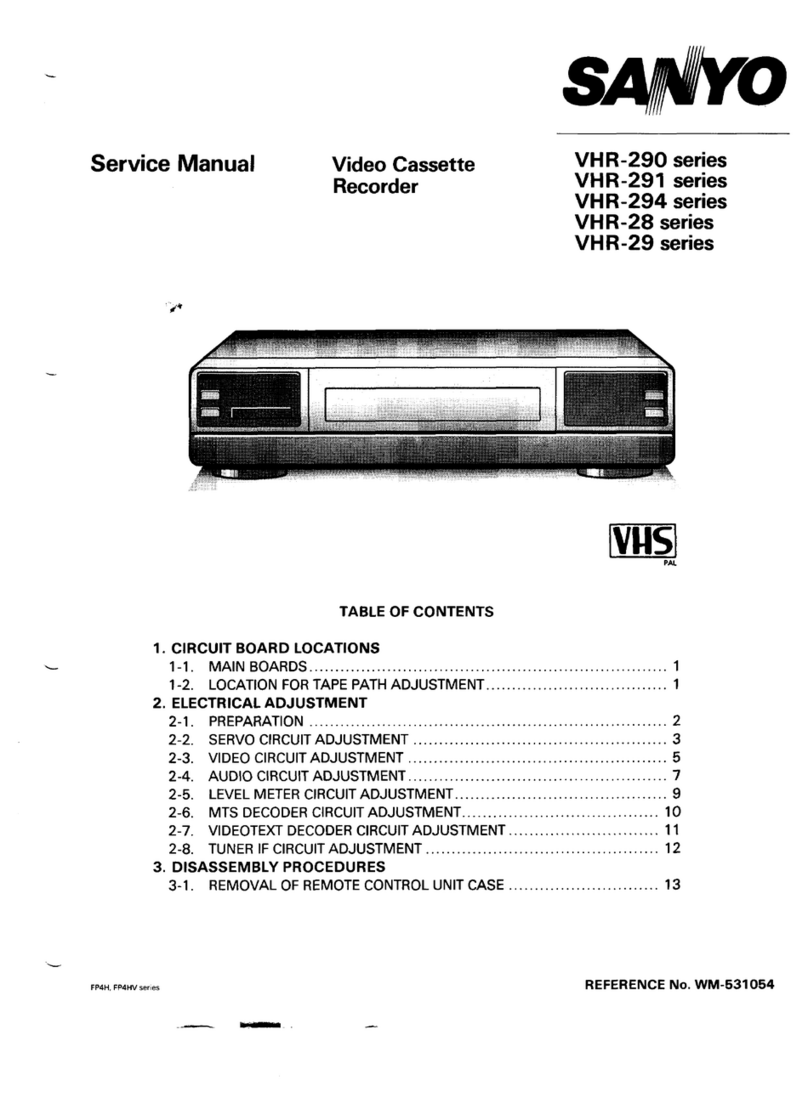

Sanyo VHR-290 Series User manual

Sanyo

Sanyo SRT-4040 User manual

Sanyo

Sanyo VHR-330 User manual

Sanyo

Sanyo VHR-810 User manual

Sanyo

Sanyo TLS-4024P User manual

Sanyo

Sanyo VHR-VT221A / NZ User manual

Sanyo

Sanyo VHR-VK920A User manual

Sanyo

Sanyo VHR-420 User manual

Sanyo

Sanyo VHR-650 User manual

Sanyo

Sanyo VHR-490 User manual

Sanyo

Sanyo VHR-279E User manual

Sanyo

Sanyo VHR-230 series User manual