FILE

NO.

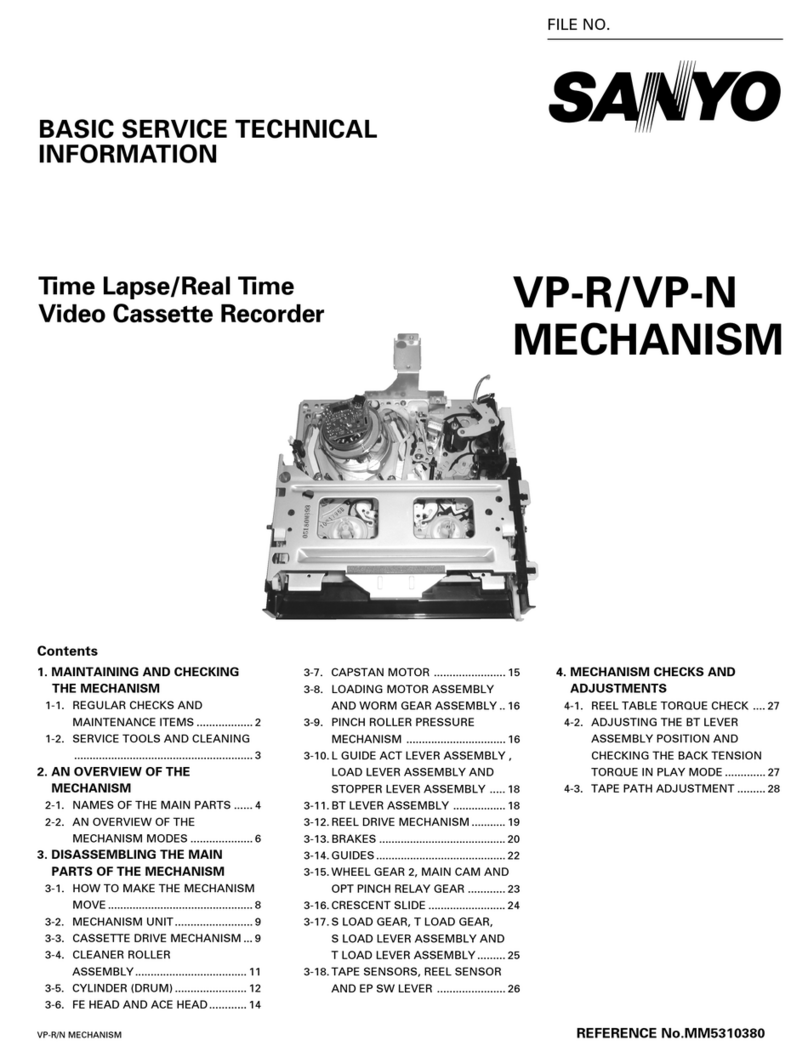

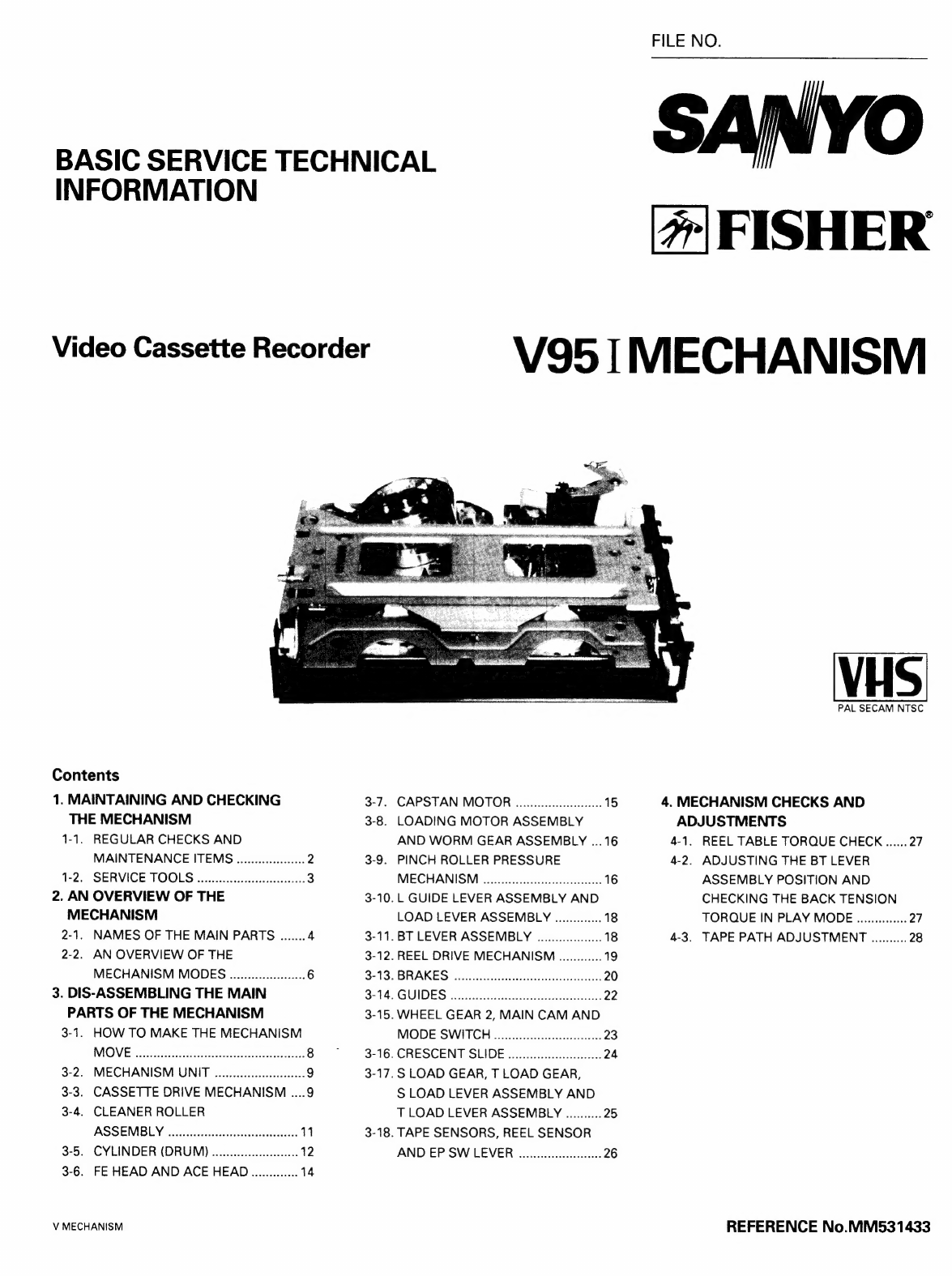

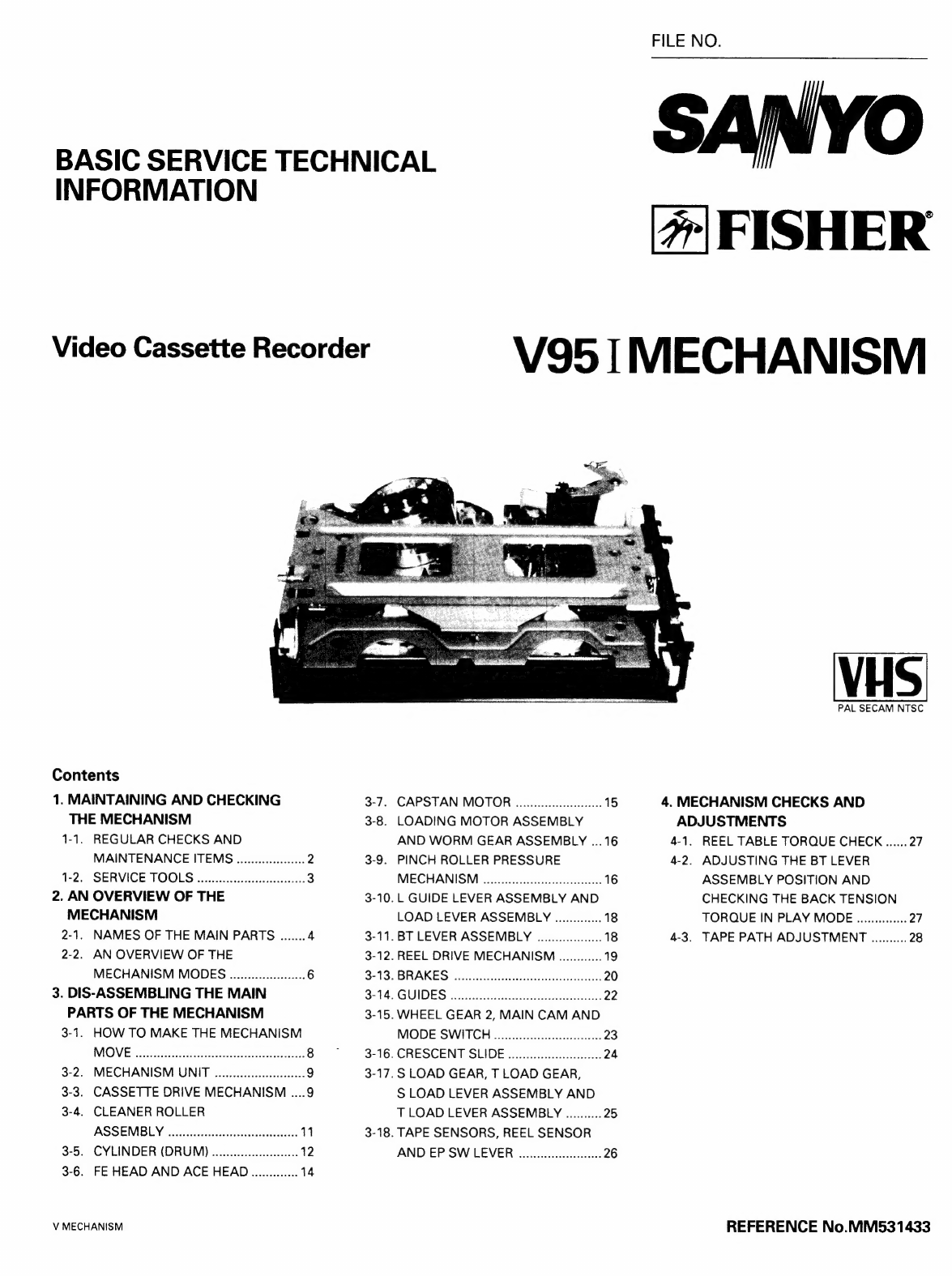

BASIC

SERVICE

TECHNICAL

SANYC

INFORMATION

4]

FISHER

Video

Cassette

Recorder

V95

[MECHANISM

VHS!

PAL

SECAM

NTSC

Contents

1.

MAINTAINING

AND

CHECKING

3-7.

CAPSTAN

MOTOR

...........00cceeeeee

15

4.

MECHANISM

CHECKS

AND

THE

MECHANISM

3-8.

LOADING

MOTOR

ASSEMBLY

ADJUSTMENTS

1-1.

REGULAR

CHECKS

AND AND

WORM

GEAR

ASSEMBLY

...

16

4-1.

REEL

TABLE

TORQUE

CHECK.......27

MAINTENANCE

ITEMS

..........0.0000e-

2

3-9.

PINCH

ROLLER

PRESSURE

4-2.

ADJUSTING

THE

BT

LEVER

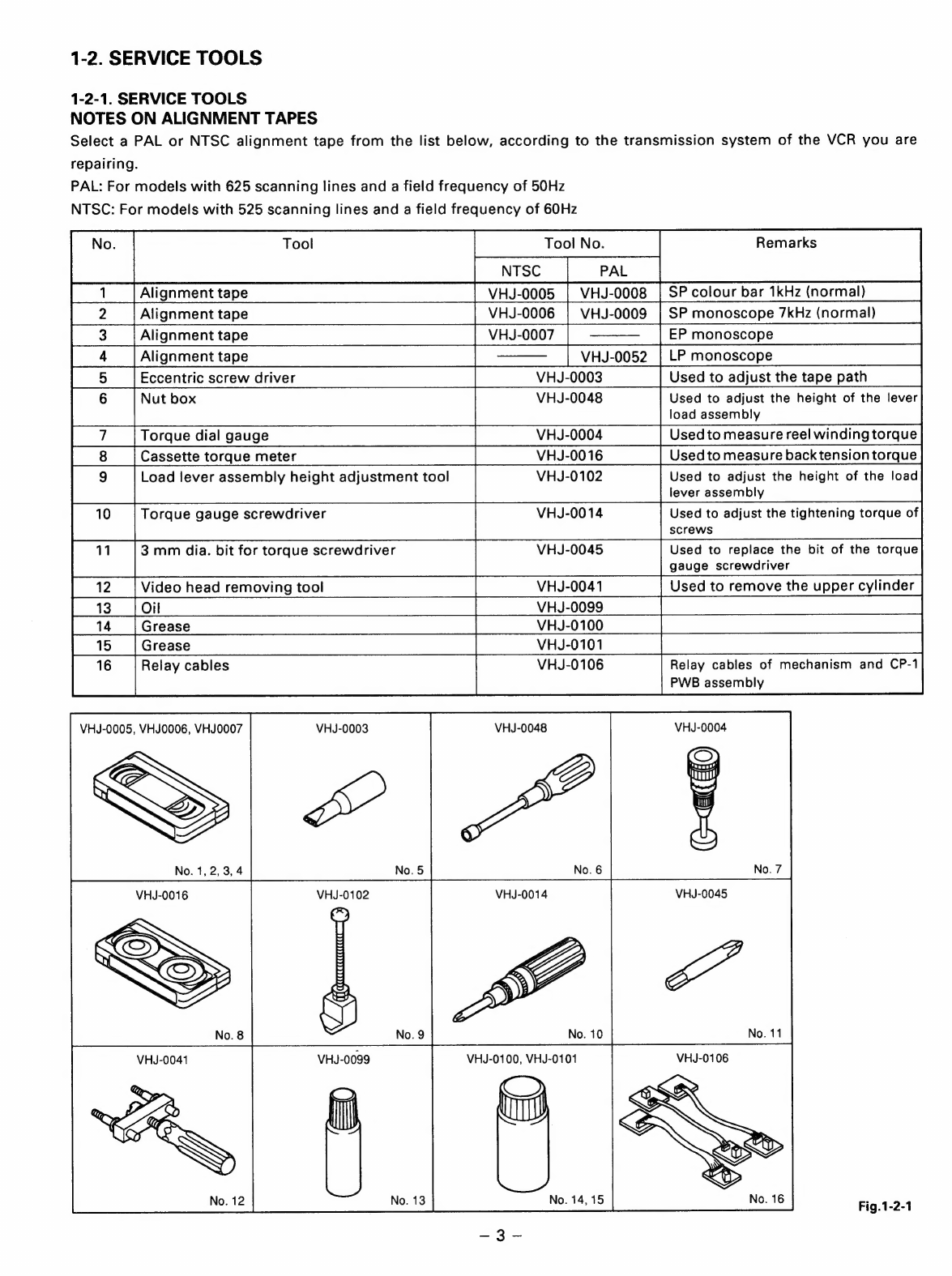

1-2.

SERVICE

TOOLS

......cceseceeeeeeeeeeee

3

MECHANISM

uu...

.ececescseseseseeceeceeeee

16

ASSEMBLY

POSITION

AND

2.

AN

OVERVIEW

OF

THE

3-10.

L

GUIDE

LEVER

ASSEMBLY

AND

CHECKING

THE

BACK

TENSION

MECHANISM

LOAD

LEVER

ASSEMBLY

.............

18

TORQUE

IN

PLAY

MODE

..............

27

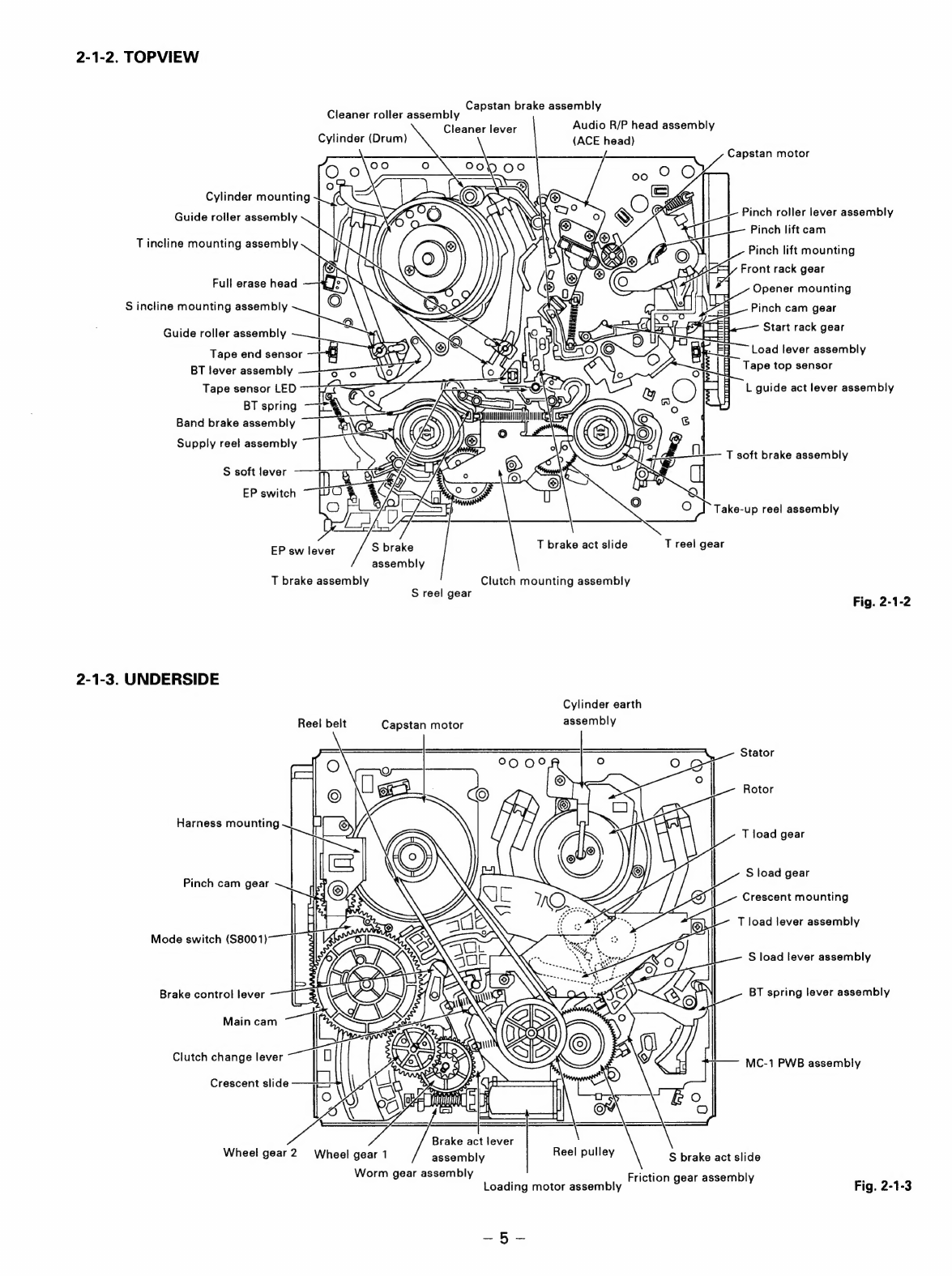

2-1.

NAMES

OF

THE

MAIN

PARTS

.......

4

3-11.

BT

LEVER

ASSEMBLY

..........00000-

18

4-3.

TAPE PATH

ADJUSTMENT

..........

28

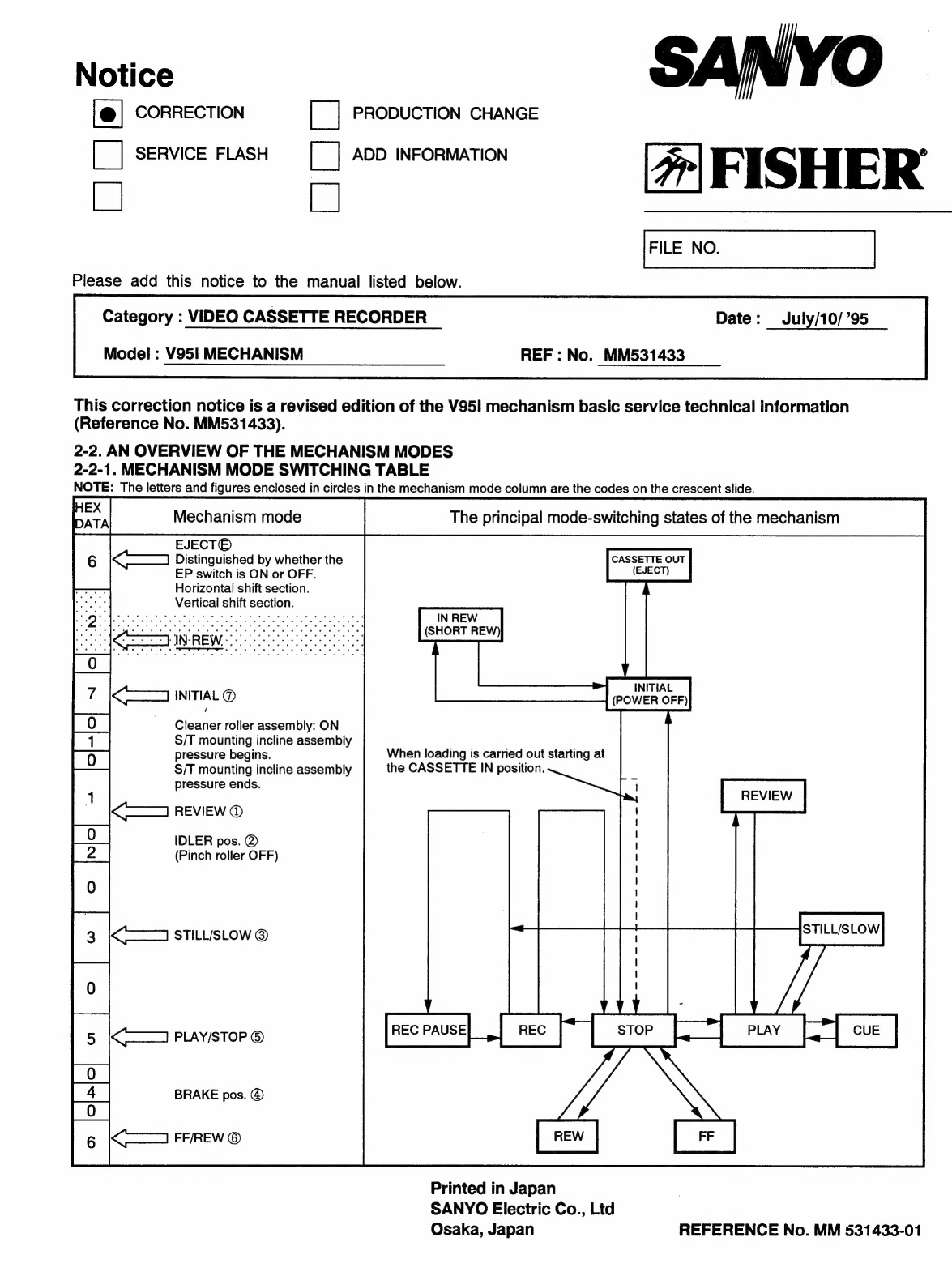

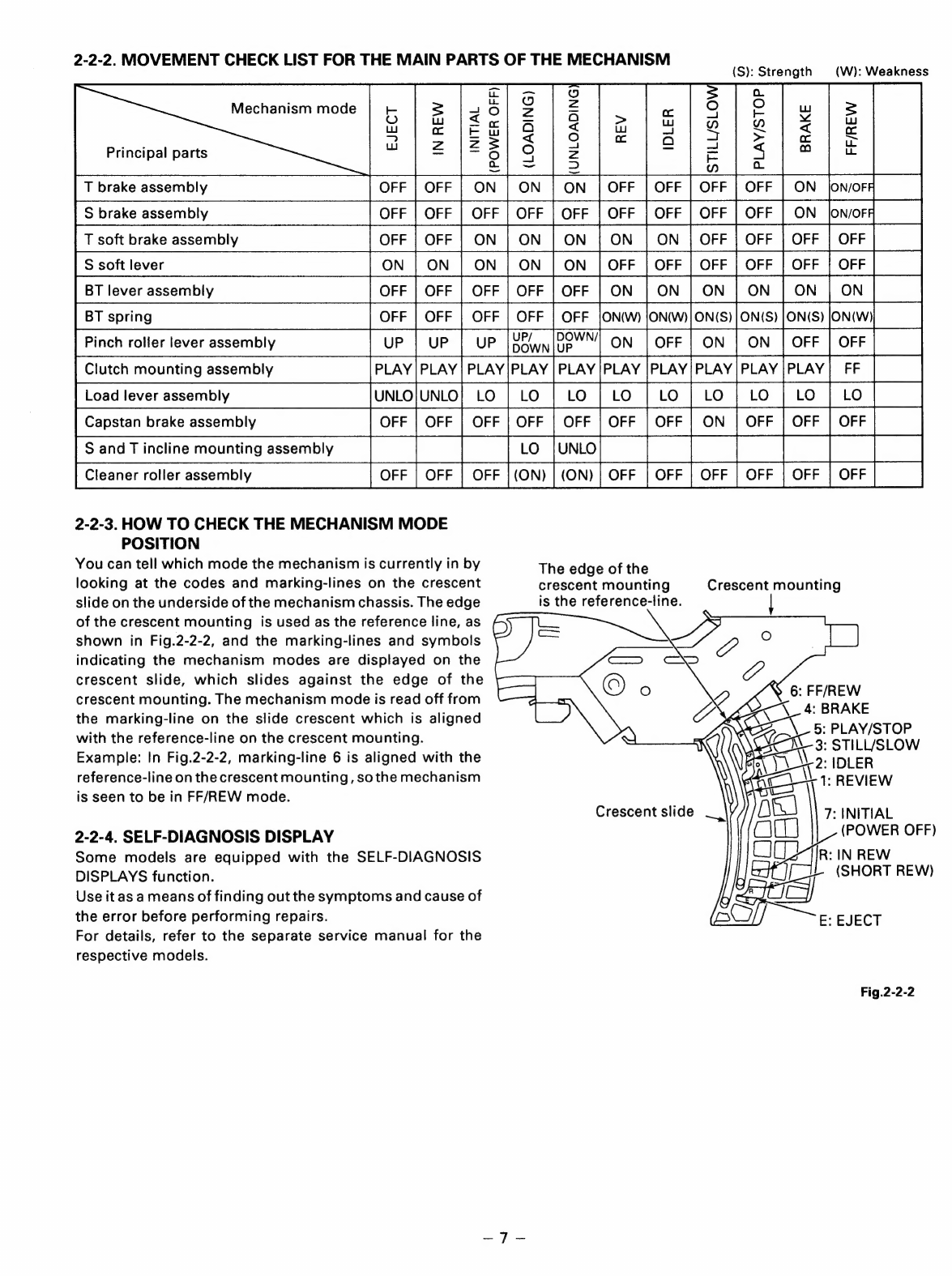

2-2.

AN

OVERVIEW

OF

THE

3-12.

REEL

DRIVE

MECHANISM

............

19

MECHANISM

MODES

............00000-

6

B13.

BRAKES

citctacsicsGearasscoreentienttitedeess

20

3.

DIS-ASSEMBLING

THE

MAIN

STS

GUIDES

swetesntadesatissonehtonssseeitencciaags

22

PARTS

OF

THE

MECHANISM

3-15.

WHEEL

GEAR

2,

MAIN

CAM

AND

3-1.

HOW

TO

MAKE

THE

MECHANISM

MODE

SWITCH

......ccseseeeeeeeeeeeeee

23

MOVEx

ea

etn

tarot

8

~°

3-16.

CRESCENT

SLIDE

uc

24

3-2.

MECHANISM

UNIT

ou...

cece.

9

3-17.

S

LOAD

GEAR,

T

LOAD

GEAR,

3-3.

CASSETTE

DRIVE

MECHANISM

....9

S

LOAD

LEVER

ASSEMBLY

AND

3-4.

CLEANER

ROLLER

T

LOAD

LEVER

ASSEMBLY

..........

25

ASSEMBLY

..u.cicecesescscsscseeeeseeeeeees

11

3-18.

TAPE

SENSORS,

REEL

SENSOR

3-5.

CYLINDER

(DRUM)

uu...

eee

12

AND

EP

SW

LEVER

....eeceeceeeeees

26

3-6.

FE

HEAD

AND

ACE

HEAD..............

14

V

MECHANISM

REFERENCE

No.MM531433