SMC Networks CKZ3N Series User manual

Other SMC Networks Industrial Equipment manuals

SMC Networks

SMC Networks ZXP7 X1 KA Series User manual

SMC Networks

SMC Networks LEY series User manual

SMC Networks

SMC Networks MGZ Series User manual

SMC Networks

SMC Networks MRQ Series Manual

SMC Networks

SMC Networks ZHP Series User manual

SMC Networks

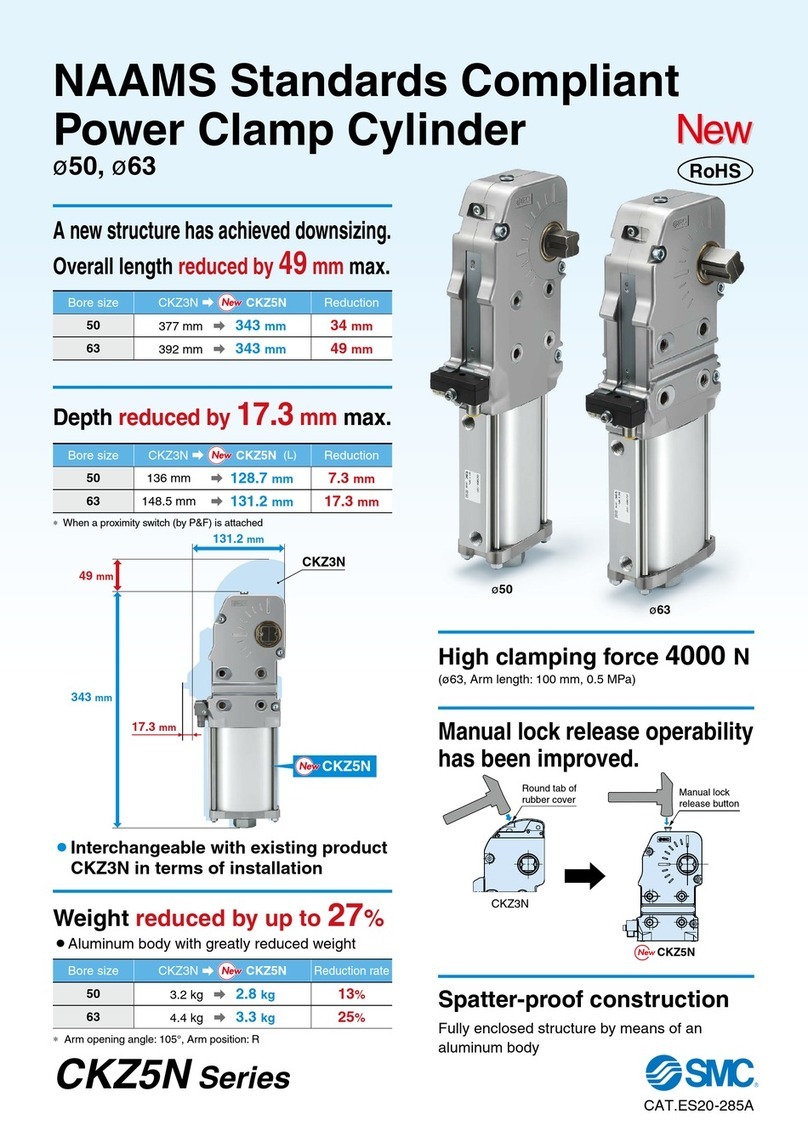

SMC Networks CKZ5N Series User manual

SMC Networks

SMC Networks SYJ3000 User manual

SMC Networks

SMC Networks XT316-30(B) User manual

SMC Networks

SMC Networks EX510 Series User manual

SMC Networks

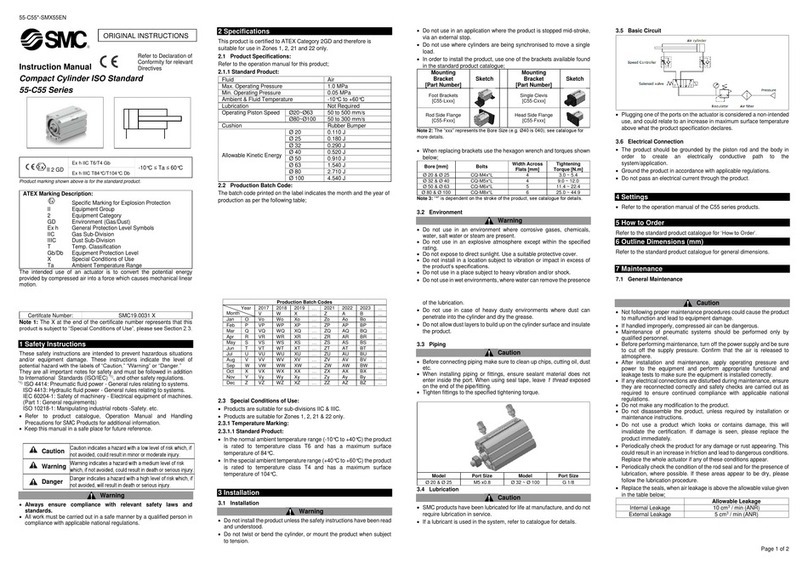

SMC Networks 55 Series User manual

SMC Networks

SMC Networks LESYH16-X171 Series User manual

SMC Networks

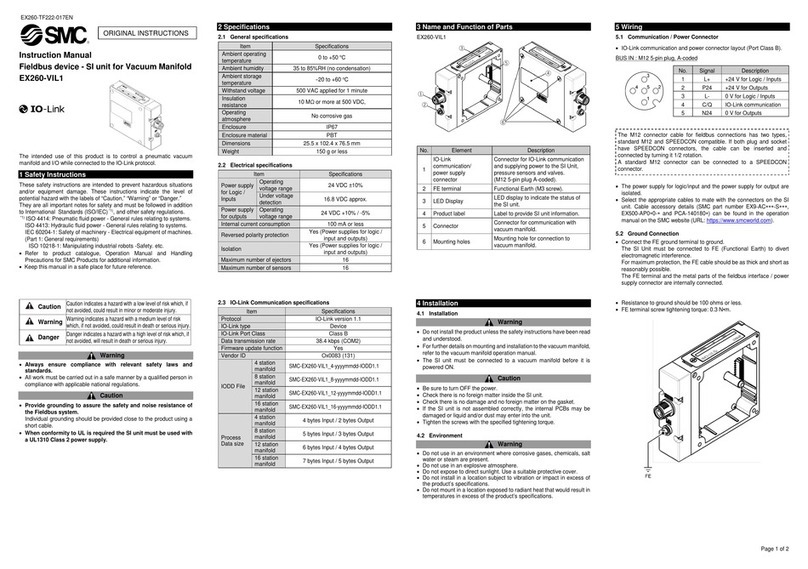

SMC Networks EX260-VIL1 User manual

SMC Networks

SMC Networks CKZT Series User manual

SMC Networks

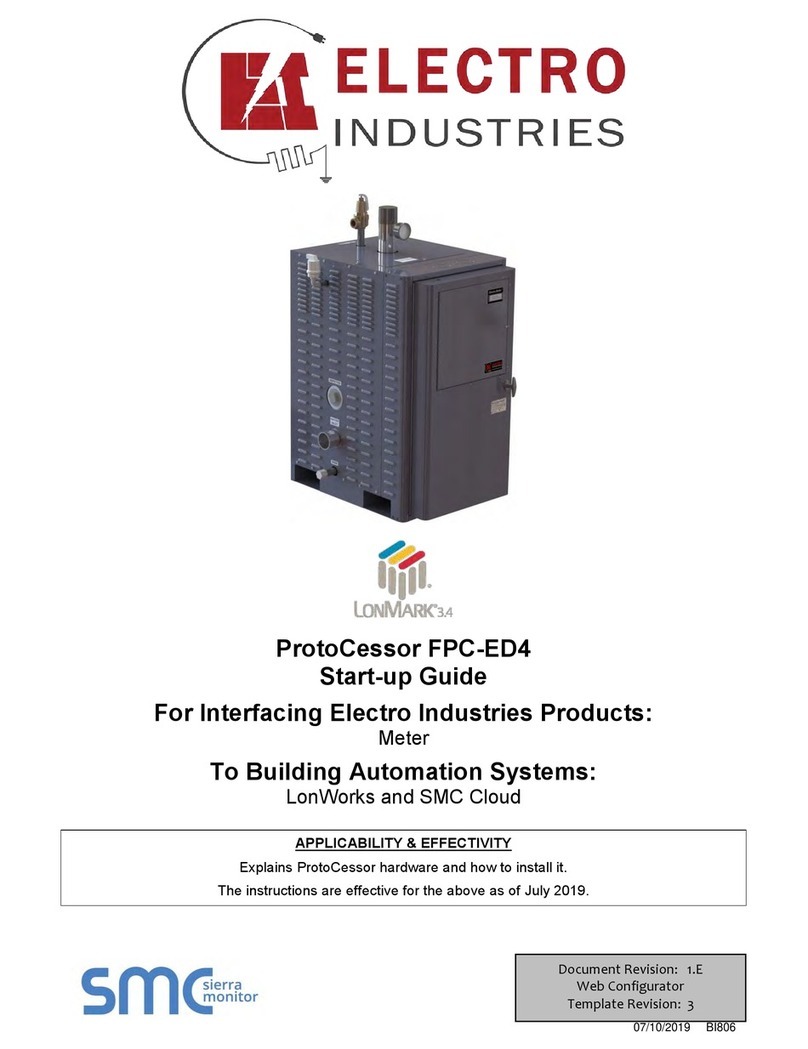

SMC Networks Electro Industries ProtoCessor User guide

SMC Networks

SMC Networks EX510-DYN3 User manual

SMC Networks

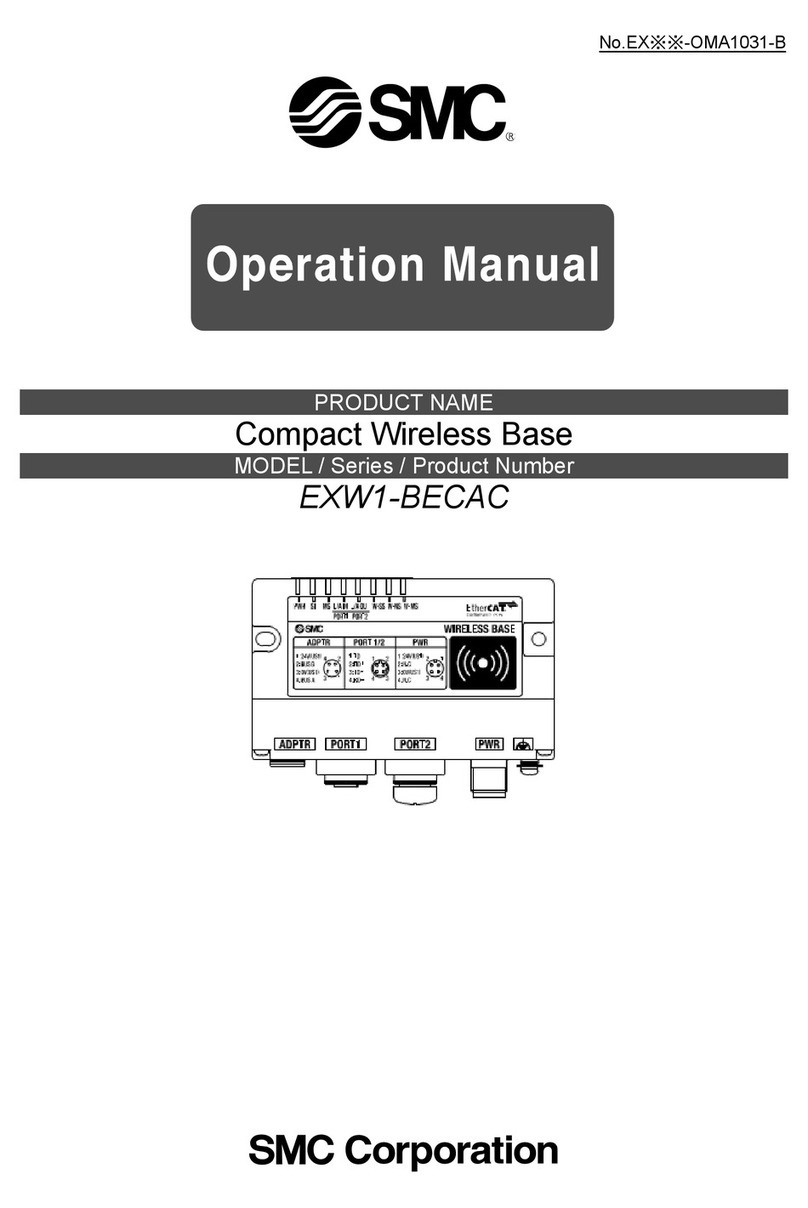

SMC Networks EXW1-BECAC User manual

SMC Networks

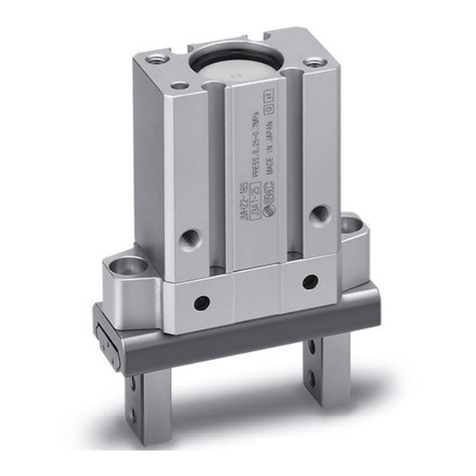

SMC Networks FHIAF-10-M G Series User manual

SMC Networks

SMC Networks MWB Series User manual

SMC Networks

SMC Networks JMHZ2-8D User manual

SMC Networks

SMC Networks ZSE20C Series User manual