SATEL INT-FI 3

2) for interface working in the test mode:

A– LED provides information on the interface A operating status:

– ON – data transmission is proceeding correctly,

– blinking – the received data are wrong,

– OFF – possible failure of the fiber cable connected to the RX socket.

B– LED provides information on the interface B operating status:

– ON – data transmission is proceeding correctly,

– blinking – the received data are wrong,

– OFF – possible failure of the fiber cable connected to the RX socket.

R– LED blinking regularly – interface running in the test mode.

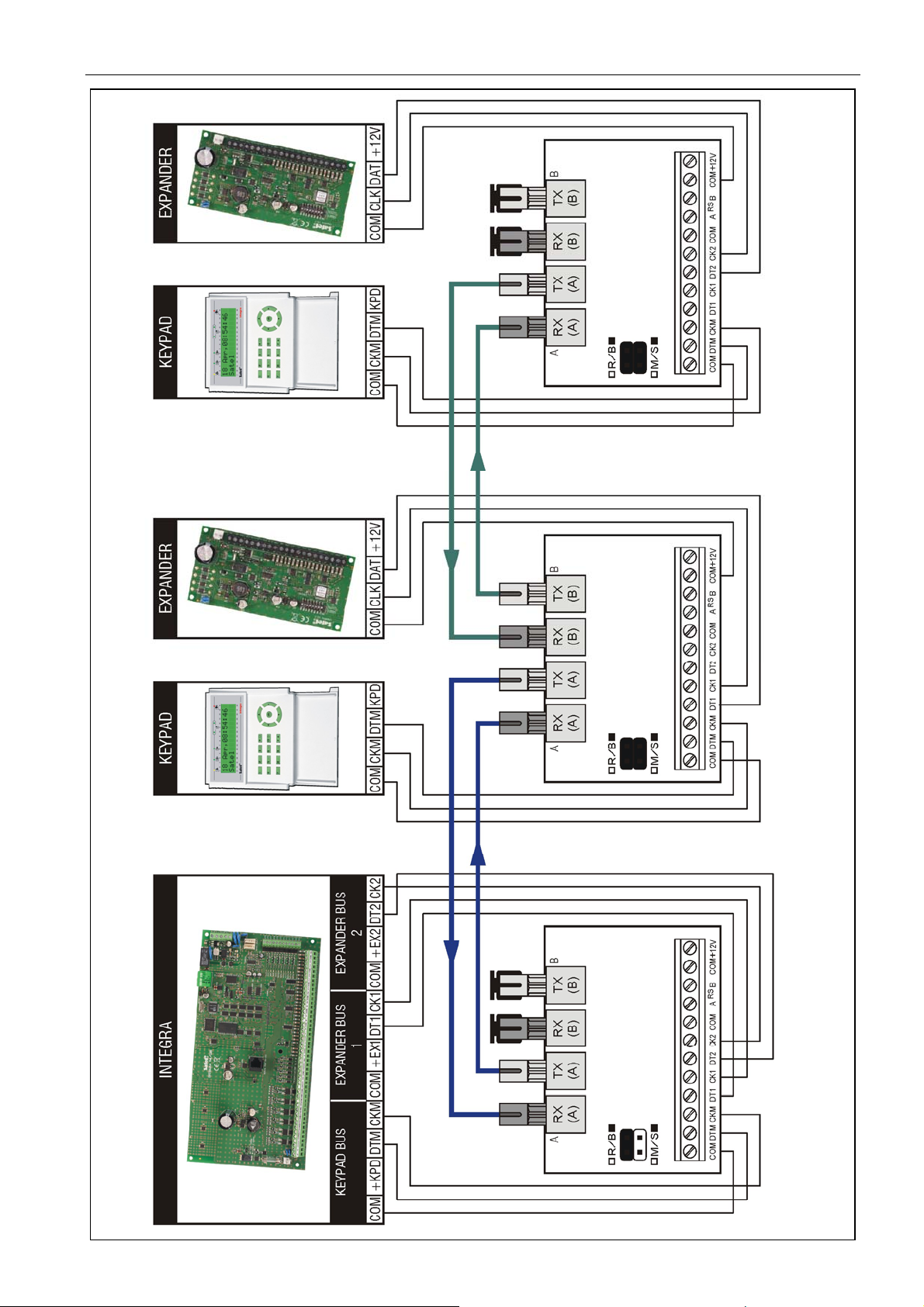

4 - ST type connectors for multimode optical fibers with a diameter of 50/125 μm or

62,5/125 μm:

A- primary connectors (RX – receive; TX – transmit),

B- expansion connectors (RX – receive; TX – transmit), the role of which depends on

how the devices are connected – see Figures 5 and 6.

5 - pins enabling the transmitter diode current to be changed, depending on the length of

optical fibers connected to A connectors.

6 - pins enabling the transmitter diode current to be changed, depending on the length of

optical fibers connected to B connectors.

7 - LED indicating power supply presence and program operation.

8 - terminals:

COM - common ground,

DTM - keypad bus data,

CKM - keypad bus clock,

DT1 - first expander bus data,

CK1 - first expander bus clock,

DT2 - second expander bus data,

CK2 - second expander bus clock,

A

RS

B - terminals for connecting RS-485 bus,

+12V - power supply input.

3. Installation

All electrical connections may only be made with disconnected power supply.

The INT-FI interface unit should be installed indoors, in spaces with normal air humidity. The

place where the unit is installed should be selected so as to ensure protection from

unauthorized access.

Connection to the INTEGRA control panel communication buses and to the source of

electrical power is to be made with a typical straight unscreened cable, as used in the

security alarm systems (using the twisted pair type of cable, e.g. UTP, STP, FTP is not

recommended). Connection to the RS-485 bus is to be made with the UTP type cable

(unscreened twisted pair). The length of optical fiber cable connecting two INT-FI interface

units can be up to 2 km.

Notes:

Configuration must be selected by placing jumpers across the R/B and M/S pins before

the power is turned on.