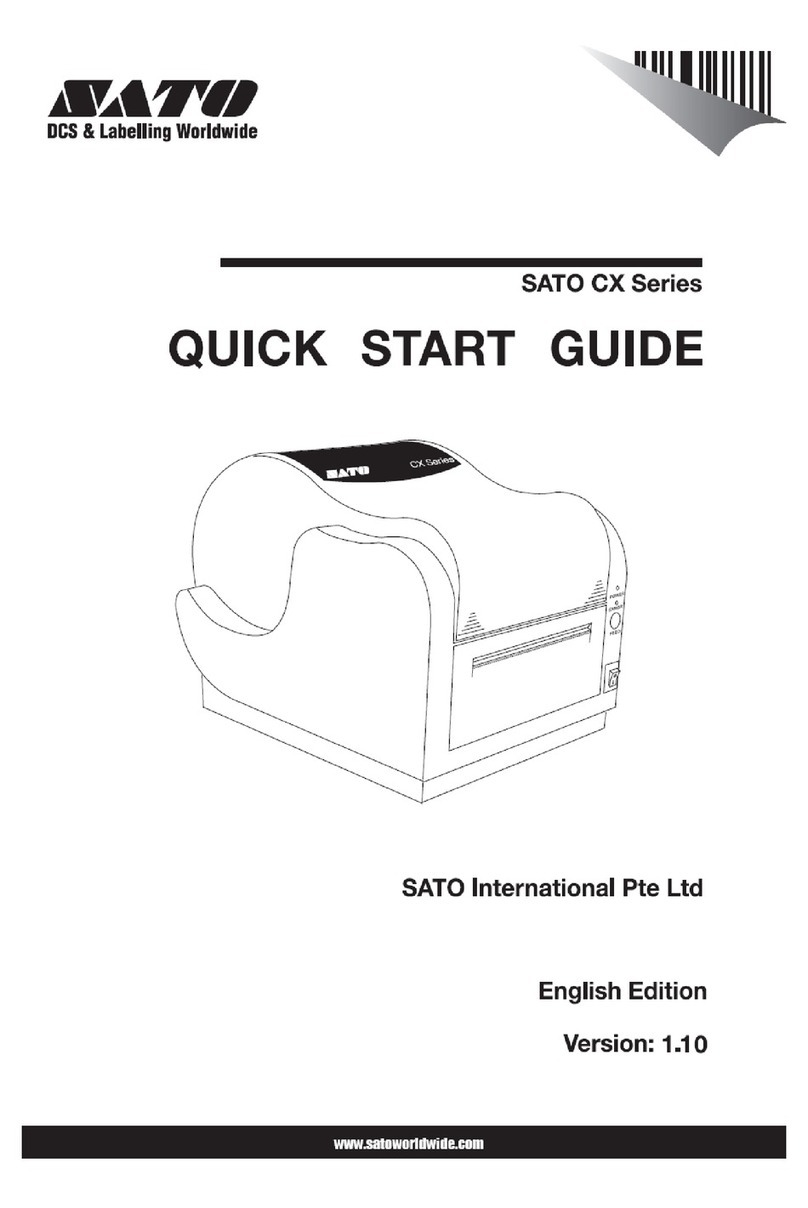

SATO RWG500 User manual

Quick Guide

for

RWG500

Label Rewinder

PN 9001128A

2

Introduction

Thank you for your purchase of the SATO RWG500 new

generation rewinder for SATO barcode printers.

This quick reference guide will lead you on a familiariza-

tion tour to help you start using the machine as soon as

possible.

To get the most out of the RWG500’s intelligent features,

make sure to read this manual carefully before using the

machine.

Table of Contents

Introduction.......................................................2

Safety Symbols ................................................3

Safety Precautions ..........................................4

FCC Notice ......................................................6

What’s In the Box ............................................7

Parts Identification ...........................................8

Parts Identification ...........................................9

Preparing the Joint Plate .................................10

Adjusting the Roller Height ...............................14

Installing the Joint Plate ...................................15

Label Setup ......................................................17

Basic Operation ...............................................23

Winding 6” labels ..............................................25

Installing the 6” Expansion Kit ..........................26

Basic Specifications..........................................27

3

Safety Symbols

About warning symbols

As a preventive measure to ensure safe usage of this

machine so as to safeguard against damage to yourself,

other people or property, several symbols and icons are

used in this guide. The following pages describe the

significance of each symbol. Please take time to read and

understand the content.

Examples

The triangle sign means ‘Be careful’.

The content within the triangle illustrates specific

hazards. In this case, the sign on

the left means ‘beware of electric shock’.

The circular sign means ‘prohibited’. The

content within the circle illustrates a specific

prohibition. In this case the sign on the left means

‘disassembly prohibited’.

The black circular sign means ‘must do’. The

content within the sign illustrates specific items

that must be carried out. In this case the sign on

the left means ‘the plug must be unplugged from

the socket’.

If this display and its warning is ignored, any

mishandling could result in death or serious

injuries.

If this display and its warning is ignored, any

mishandling could result in serious injuries as

well as damage to properties.

Caution

4

Safety Precautions

Do not place on an unstable place

Do not place the rewinder on an unstable place

such as an unsteady table, an inclined place or

a place with vibration. The rewinder may drop

or topple over and cause injuries.

Liquids

Do not place any containers with water or

chemicals, such as flower vases or cups, as

well as small metallic objects near the rewinder.

Continued use creates the danger of fire or

electrical shock.

* If any of these should fall into the rewinder,

immediately turn off the power and contact your

nearest dealer or service center.

Foreign Matter

Do not drop or insert metallic or flammable

objects into the openings on the rewinder.

Continued use creates the danger of fire or

electrical shock.

* If any of these should fall into the rewinder,

immediately turn off the power and contact your

nearest dealer or service center.

Dropping and Damage

Do not use if the product has been dropped or

damaged. Continued use creates the danger of

fire and electrical shock.

* Should the rewinder ever fall or otherwise

become damaged, immediately turn off the

power and contact your nearest dealer or

service center. Continued use creates the

danger of fire or electrical shock.

Caution

Caution

5

Abnormal Conditions

Do not use the rewinder if it is emitting smoke

or strange odors. Continued use creates the

danger of fire and electrical shock.

* Immediately turn off the power and contact

your nearest dealer or service center for

repairs. Do not try to service the rewinder by

yourself.

Disassembly

Never try to take the unit apart or modify it in

any way. Doing so creates the danger of fire or

electrical shock. Contact your nearest dealer or

service center for repairs.

Location

Do not locate the rewinder in areas subjected to

high humidity or dew. Doing so creates the

danger of electrical shock.

* If dew forms inside the rewinder, immediately

turn off the power and do not use it until it has

dried up.

FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE.

REPLACE ONLY SAME TYPE AND RATING

OF FUSE.

LOCATION : F1 , F2 RATING : 125V 3.5A

Caution

Caution

6

FCC Notice

This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful

interference in a residential installation.

This equipment generates use and can radiate radio frequency energy and, if

not installed and used in accordance with instructions, may cause harmful

interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation.

If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the

following measures:

- Reorient or re locate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

7

What’s In the Box

RWG500 main unit Joint plate

EXT cable

Label Clip

3-inch core x 2 Label Guide

Quick Guide

8

Parts Identification

Second roller

First roller

Tension arm

Rewind

Start/Stop

button

Status

LED

Direction

Indicator LED:

Clockwise

winding

(face in)

Direction

Indicator LED:

Counter-clock-

wise winding

(face out)

Stopper

Plate

Rewind

Core

9

Parts Identification

Selector for

clockwise or

counterclock-

wise rewind

direction

Socket for

AC adaptor

EXT connector

(links to printer)

Earth

terminal

Power

Switch

10

Preparing the Joint Plate

The joint plate aligns the base of the RWG500 to the

base of a SATO printer. This alignment ensures a smooth

label path and prevents problems during long periods of

continuous operation.

The following procedure adjusts the joint plate to suit the

base of different SATO printers, as shown here:

1

2

Use a Phillips

screwdriver

to loosen the

two screws

that secure

the movable

portion of the

joint plate.

Slide the movable

portion of the joint

plate in various

directions to

reveal the names

of various SATO

printer models.

Main plate

Movable plate

11

Preparing the Joint Plate (cont’d)

To prepare the joint plate for a GTx4XXe or M-84Pro

series printers:

When the movable plate

reveals “GTx4XXe” and

“M-84Pro”, adjust its

position so that each pro-

truding stub (called a

boss) on the underside of

the movable plate will fit

neatly into two comple-

mentary holes on the

main plate. The movable

plate will not slide easily

now. Tighten the two

screws which were loos-

ened in Step 1. Top of

movable

plate

Boss

Boss

Underside

of movable

plate

12

Preparing the Joint Plate (cont’d)

To prepare the joint plate for the M-5900RVe printer:

Top of

movable

plate

Boss

Boss

Underside

of movable

plate

Wh

en t

h

e mova

bl

e

plate reveals “MT4XXe”

and “M-5900RVe”,

adjust its position so

that each protruding

stub (called a boss) on

the underside of the

movable plate will fit

neatly into two comple-

mentary holes on the

main plate. The mov-

able plate will not slide

easily now. Tighten the

two screws which were

loosened in Step 1.

13

Preparing the Joint Plate (cont’d)

To prepare the joint plate for the CL6XXe series printers:

Top of

movable

plate

Boss

Boss

Underside

of movable

plate

Wh

en t

h

e mova

bl

e

plate reveals

“MR6XXe” and

“CL6XXe”, adjust its

position so that each

protruding stub (called

a boss) on the under-

side of the movable

plate will fit neatly into

two complementary

holes on the main plate.

The movable plate will

not slide easily now.

Tighten the two screws

w

hich were loosened in

Step 1.

14

Adjusting the Roller Height

Before the rewinder is guided into place in front of the

printer, the height of its first roller has to be adjusted to

one of two positions (upper or lower) to fit the printer,

based on the table below:

Roller Height settings for SATO Printers

Model Roller Height

GTx4XXe Lower position

CL6XXe Lower position

CL4XXe Upper position

M-84Pro Upper position

M-5900RVe Upper position

Roller in Upper

position

Roller in lower

position

Install two locking screws here

Install

two

locking

screws

here

15

Installing the Joint Plate

To align the printer to the RWG500 using the joint plate:

1Place the non-movable

holes of the joint plate

under the feet of the

rewinder as shown. The

holes of the movable

plate should be facing

away from the rewinder.

2Connect the Frame

Ground wire of the joint

plate to the Earth termi-

nal on the rewinder.

Use a Phillips screw-

driver if necessary.

Earthing completed

16

Installing the Joint Plate (cont’d)

3Now place the printer

so that its feet at the

label output side will fit

into the positioning

holes on the joint place.

4Make sure both the

printer and the rewinder

are turned OFF.

Locate the EXT con-

nector of the printer and

use the supplied EXT

cable to connect the

printer to the rewinder’s

EXT connector.

Make sure that the

printer and rewinder are

aligned properly using

the joint plate. Other-

wise rewinding errors

may occur.

Caution

17

Label Setup

The RWG500 offers two rewind directions and two types

of rewind shafts, as follows:

Rewinding Direction: Face in (CW) / Face Out (CCW)

Rewinding Shaft: Direct rewind/3” paper core rewind

About Rewinding Direction

Counterclockwise

winding (CCW)

Clockwise

winding (CW)

In a CCW winding

direction, the printed

surface of the label is

always visible as it

faces outwards.

In a CW winding direction,

the printed surface of the

label faces inwards and is

hidden from view. Only

the backing sheet (label

liner) faces outwards. The

rewind is set by default to

CW rewinding.

18

Label Setup (cont’d)

To change the rewind direction, use the Direction switch

found on the side panel of the rewinder. The factory set-

ting is CW rewinding by default.

Change the rewind direction only when the rewinder is in

an idling state, or when it is turned OFF.

Setting Rewind Direction

1. Before changing the rewind direction, make sure

the rewinder is turned OFF, or make sure that the

Status LED is blinking in green (rewinder in Idling

state)

2. Locate the Direction switch at the side panel, and

set it to either CW (clockwise, face in) or CCW

(counterclockwise, face-out).

3. Check the control panel display to confirm that the

appropriate CW or CCW LED is lit.

Caution

19

Label Setup (cont’d)

Besides setting the rewind direction, you can set up the

rewinder for direct rewinding or rewinding using a 3”

paper core.

About Direct Rewinding

Use direct rewinding when a paper core is not to be

used, and the label being collected will not need

reprinting or reprocessing in future.

1Set the rewinder for

CW or CCW rewind

direction and load

the label accord-

ingly. Wind the label

at the rewinding

shaft, and insert the

provided label clip

to fasten the label

onto the shaft.

2Now insert the label

guide. The label

output from the

printer is now set

for direct rewinding.

20

Label Setup (cont’d)

You can collect output labels onto a 3” paper core for

more consistent winding, and if the wound label needs to

be unwound later for reprocessing/reprinting.

Rewinding on a 3” paper core

1If label width is

below 65 mm,

attach one of the

provided 3” core

adaptors to the

rewinding shaft.

Otherwise, use two

adaptors. The

adaptor(s) should

be inserted so that

the metal plate teeth faces in the same direc-

tion*as the rewind direction. Screw the adap-

tor(s) into the narrow groove of the shaft.

2Space the adaptor(s)

along the shaft to fit

the label width, then

tighten each locking

screw. Make sure the

screw fits into the

metal nut sliding

along the groove.

* For CW and CCW rewinding, the metal

teeth must face left or right respectively.

Other manuals for RWG500

2

Table of contents

Other SATO Label Maker manuals

SATO

SATO CX200 User manual

SATO

SATO CL4NX RIDF Owner's manual

SATO

SATO Argox O4-250 User manual

SATO

SATO s84ex User manual

SATO

SATO CL4NX RIDF Instruction sheet

SATO

SATO CX Series User manual

SATO

SATO MB 200i User manual

SATO

SATO s86ex User manual

SATO

SATO SG112-ex User manual

SATO

SATO TG3 Series User manual