SATO LC400e Series Owner's manual

Copyrights

Any unauthorized reproduction of the contents of this document, in part or whole, is strictly prohibited.

Limitation of Liability

SATO Corporation and its subsidiaries in Japan, the U.S and other countries make no representations or

warranties of any kind regarding this material, including, but not limited to, implied warranties of

merchantability and fitness for a particular purpose. SATO Corporation shall not be held responsible for errors contained

herein or any omissions from this material or for any damages, whether direct, indirect, incidental or consequential, in

connection with the furnishing, distribution, performance or use of this material.

Specifications and contents in this document are subject to change without notice.

Trademarks

SATO is a registered trademark of SATO Holdings Corporation and its subsidiaries in Japan, the U.S. and other

countries.

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

All other trademarks are the property of their respective owners.

Version: LC408e/LC412e-r01-05-26-17PR

©2017 SATO Corporation. All rights reserved.

Table of Contents

1. Outline ........................................................................................................................................................................... 7

2. Motion Setting Default Value..................................................................................................................................... 7

3. Font Table ..................................................................................................................................................................... 9

4. View Point of Command Manual ............................................................................................................................ 11

5. Control Command..................................................................................................................................................... 13

5.1 ESC+A Data Send Start ....................................................................................................................................... 13

5.2 ESC+Z Data Send End......................................................................................................................................... 14

5.3 ESC+Q Print Number ........................................................................................................................................... 15

5.4 ESC+ID Job ID Number ....................................................................................................................................... 16

5.5 ESC+WK Job Name............................................................................................................................................. 17

5.6 ESC+RK RFID Write............................................................................................................................................. 18

6. Print Position Command.......................................................................................................................................... 20

6.1 ESC+H Print Horizontal Position.......................................................................................................................... 20

6.2 ESC+V Print Vertical Position............................................................................................................................... 21

7. Modification Command............................................................................................................................................ 22

7.1 ESC+P Character Pitch ........................................................................................................................................ 22

7.2 ESC+L Enlargement ............................................................................................................................................. 23

7.3 ESC+PS Proportional Pitch.................................................................................................................................. 24

7.4 ESC+PR Release Proportional Pitch................................................................................................................... 25

7.5 ESC+% Rotate ...................................................................................................................................................... 26

7.6 ESC+F Sequential Number.................................................................................................................................. 27

7.7 ESC+FW Ruler and Frame Print ......................................................................................................................... 28

7.8 ESC+( Black/White Inversion Print....................................................................................................................... 29

7.9 ESC+KC Kanji Code............................................................................................................................................. 30

7.10 ESC+& Form Overlay Registration.................................................................................................................... 31

7.11 ESC+/ Form Overlay Recall ............................................................................................................................... 32

7.12 ESC+0 Part Editing Function.............................................................................................................................. 33

7.13 ESC+WD Copy within Labels (Part Copy)........................................................................................................ 34

7.14 ESC+J Journal Print............................................................................................................................................ 36

7.15 ESC+RF Font / Logo Search Print..................................................................................................................... 37

7.16 ESC+RM Mirror Rotate....................................................................................................................................... 38

7.17 ESC+_D Variable Data....................................................................................................................................... 40

7.18 ESC+_Q Label Print Number............................................................................................................................. 41

7.19 ESC+RI Label Size ............................................................................................................................................. 42

7.20 ESC+RW Sheet Unit Copy Number.................................................................................................................. 43

7.21 ESC+RC Sheet Unit Cut Number...................................................................................................................... 44

7.22 ESC+RT Print Order ........................................................................................................................................... 45

7.23 ESC+RE Telegraphic Message End................................................................................................................. 46

7.24 ESC+RS Sheet Sending .................................................................................................................................... 47

7.25 ESC+WS Work Shift Information Print .............................................................................................................. 48

7.26 ESC+RZ RFID Message Print Registration ...................................................................................................... 49

8. Font Command .......................................................................................................................................................... 50

8.1 ESC+XU XU Font (Basic Size 5X9 dot) .............................................................................................................. 50

8.2 ESC+XS XS Font (Basic Size 17 X 17 dot) ........................................................................................................ 52

8.3 ESC+XM XM Font (Basic Size 24 X 24 dot)....................................................................................................... 54

8.4 ESC+XB XB Font (Basic Size 48 X 48 dot) ........................................................................................................ 56

8.5 ESC+XL XL Font (Basic Size 48 X 48 dot) ......................................................................................................... 58

8.6 ESC+OA OCR-A Font .......................................................................................................................................... 60

8.7 ESC+OB OCR-B Font .......................................................................................................................................... 62

8.8 ESC+$ Outline Font Shape .................................................................................................................................. 64

8.9 ESC+$= Outline Font Print ................................................................................................................................... 65

8.10 ESC+RD CG Font............................................................................................................................................... 67

8.11 ESC+K1 16X16 dot Horizontal Text Flow Kanji (Valid Specification of JIS or Shift JIS)................................ 70

8.12 ESC+K2 24 X 24 dot Horizontal Text Flow Kanji (Valid Specification of JIS or Shift JIS).............................. 71

8.13 ESC+K8 16 X 16 dot Horizontal Text with Mixture of half-sized, full-sized Kanji (Valid Specification of Shift

JIS)................................................................................................................................................................................ 72

8.14 ESC+K9 24 X 24 dot Horizontal Text with Mixture of Half-sized, Full-sized Kanji (Valid Specification of Shift

JIS)................................................................................................................................................................................ 73

8.15 ESC+k1 16X16 dot Vertical Text Flow Kanji (Valid Specification of JIS or Shift JIS)..................................... 74

8.16 ESC+k2 24 X 24 dot Vertical Text Flow Kanji (Valid Specification of JIS or Shift JIS)................................... 75

8.17 ESC+k8 16X16 dot Vertical Text with Mixture of Half-sized, Full-sized Kanji (Valid Specification of Shift JIS)

...................................................................................................................................................................................... 76

8.18 ESC+k9 24 X 24 dot Vertical Text with Mixture of Half-sized, Full-sized Kanji (Valid Specification of Shift

JIS)................................................................................................................................................................................ 77

8.19 ESC+T1 16 X 16 dot External Word Registration............................................................................................. 78

8.20 ESC+T2 24 X 24 dot External Word Register................................................................................................... 80

8.21 ESC+K1(K2) External Character Re-Call Horizontal Text Flow ...................................................................... 82

8.22 ESC+k1(k2) External Character Re-Call Vertical Text Flow............................................................................ 83

9. Barcode Specification Outline ................................................................................................................................ 84

9.1 ESC+B Barcode (Ratio 1:3) ................................................................................................................................. 87

9.2 ESC+D Barcode (ratio 1 : 2)................................................................................................................................. 89

9.3 ESC+D~ESC+d Barcode (Explanation Word Selection)................................................................................... 91

9.4 ESC+BD Barcode (ratio 2 : 5) .............................................................................................................................. 92

9.5 ESC+BT Barcode Ratio Registration................................................................................................................... 94

9.6 ESC+BW Barcode Print from Ratio ..................................................................................................................... 95

9.7 ESC+BI UCC/EAN128 <for Standard Carton ID>.............................................................................................. 98

9.8 ESC+BC CODE93 Barcode............................................................................................................................... 100

9.9 ESC+BG CODE128 Barcode ............................................................................................................................ 102

9.10 ESC+BF Bookland............................................................................................................................................ 106

9.11 ESC+BP Postnet............................................................................................................................................... 108

9.12 ESC+BS USPS Barcode.................................................................................................................................. 110

9.13 ESC+EU Composite Symbol ........................................................................................................................... 112

9.14 ESC+BL UPC-A Barcode (Without HRI)......................................................................................................... 116

9.15 ESC+BL~ESC+d UPC-A Barcode (With HRI) ............................................................................................... 117

9.16 ESC+BM UPC-A Barcode (With HRI)............................................................................................................. 119

10. 2-D Code Command ............................................................................................................................................. 120

10.1 ESC+BQ QR Code........................................................................................................................................... 120

10.2 ESC+BV MAXI Code........................................................................................................................................ 145

10.3 ESC+BK PDF417 ............................................................................................................................................. 147

10.4 ESC+BX Data Matrix ........................................................................................................................................ 150

10.5 ESC+DC Data Matrix Data............................................................................................................................... 151

10.6 ESC+FX Data Matrix Sequential Number....................................................................................................... 152

10.7 ESC+2D10 PDF417 ......................................................................................................................................... 154

10.8 ESC+2D12 Micro PDF417 ............................................................................................................................... 156

10.9 ESC+2D20 MAXI Code.................................................................................................................................... 159

10.10 ESC+2D30 QR Code (Model 2) .................................................................................................................... 161

10.11 ESC+2D31 QR Code (Model 1) .................................................................................................................... 165

10.12 ESC+2D32 Micro QR Code........................................................................................................................... 168

10.13 ESC+2D50 DataMatrix (ECC200)................................................................................................................. 193

10.14 ESC+2D51 GS1 DataMatrix .......................................................................................................................... 196

11. Graphic Command................................................................................................................................................ 199

11.1 ESC+G Graphic Print........................................................................................................................................ 199

11.2 ESC+GM BMP File Print .................................................................................................................................. 200

11.3 ESC+GP PCX File Print ................................................................................................................................... 201

12. System Command ................................................................................................................................................ 202

12.1 ESC+CS Print Speed ....................................................................................................................................... 202

12.2 ESC+#E Print Darkness ................................................................................................................................... 203

12.3 ESC+A1 Label Size .......................................................................................................................................... 204

12.4 ESC+A3 Correction Pitch .................................................................................................................................206

12.5 ESC+AX Print Area Expand............................................................................................................................. 208

12.6 ESC+AR Print Area Standard .......................................................................................................................... 209

12.7 ESC+EP Print End Position.............................................................................................................................. 210

12.8 ESC+~(NULL) Multiple Cut .............................................................................................................................. 211

12.9 ESC+~A Cut Unit Number ............................................................................................................................... 212

12.10 ESC+~B Feed Cut Motion.............................................................................................................................. 213

12.11 ESC+* Clear .................................................................................................................................................... 214

12.12 ESC+@ OffLine .............................................................................................................................................. 215

12.13 ESC+C Re-print .............................................................................................................................................. 216

12.14 ESC+PG Printer Motion Register .................................................................................................................. 217

12.15 ESC+PC Printer Motion Register................................................................................................................... 220

12.16 ESC+E Automatic Line Feed ......................................................................................................................... 223

12.17 ESC+LD User Download ............................................................................................................................... 224

12.18 ESC+EX Memory Area Enlarge .................................................................................................................... 225

12.19 ESC+KM Kanji Mincho Style.......................................................................................................................... 226

12.20 ESC+KG Kanji Gothic Style ........................................................................................................................... 227

12.21 ESC+TW Option Waiting Time...................................................................................................................... 228

12.22 ESC+TK Forced Tear Off............................................................................................................................... 229

13. Memory Card Command...................................................................................................................................... 230

13.1 ESC+CC Card Slot ........................................................................................................................................... 230

13.2 ESC+BJF Memory Card Default...................................................................................................................... 231

13.3 ESC+BJS Memory Card Status Print.............................................................................................................. 232

13.4 ESC+&S Form Overlay Register ..................................................................................................................... 233

13.5 ESC+&R Form Overlay Re-Call....................................................................................................................... 236

13.6 ESC+YS Format Register ................................................................................................................................ 237

13.7 ESC+/N Field Register...................................................................................................................................... 240

13.8 ESC+YR Format Re-Call.................................................................................................................................. 241

13.9 ESC+/D Field Print ............................................................................................................................................ 242

13.10 ESC+GI Graphic Register .............................................................................................................................. 243

13.11 ESC+GR Graphic Re-Call.............................................................................................................................. 244

13.12 ESC+GT BMP File Register........................................................................................................................... 245

13.13 ESC+GC BMP File Re-Call............................................................................................................................ 246

13.14 ESC+PI PCX File Register............................................................................................................................. 247

13.15 ESC+PY PCX File Re-Call............................................................................................................................. 248

13.16 ESC+* Clear (memory card) .......................................................................................................................... 249

13.17 ESC+BJ, ESC+BJD True Type Font Register ............................................................................................. 250

13.18 ESC+BJT True Type Font Re-Call ................................................................................................................ 251

14. Calendar Command.............................................................................................................................................. 252

14.1 ESC+WT Calendar Setting .............................................................................................................................. 252

14.2 ESC+WP Calendar Calculation ....................................................................................................................... 253

14.3 ESC+WA Calendar Print .................................................................................................................................. 254

7

1. Outline

This is the Command Specification for LC400e Series and Overseas ‘e’ Series.

This ‘e’ Series is a general name of printers of Scantro Enhance (CL408e/412e, CL608e/612e, M-8400RVe, M-84Pro, M-5900RVe),

S Series (M-8485Se, M-8490Se, M-8460Se, M-8459Se), M-10e.

In this specification, Dip Switch for setting purpose is shown as DSW.

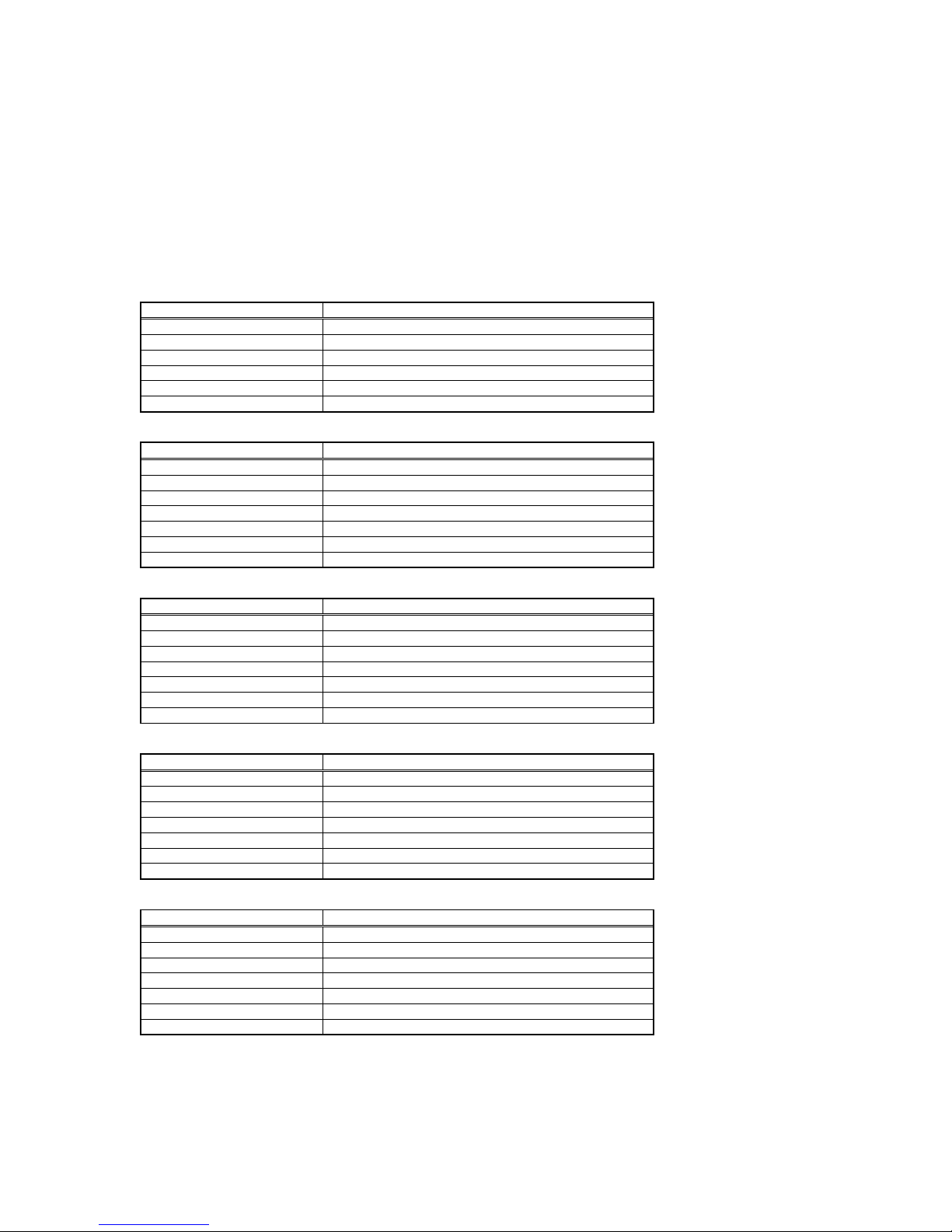

2. Motion Setting Default Value

The following is the Motion Setting Default Value

LC408e/412e

Item

Default Value

Print Speed

4 inch/sec(100mm/sec) “range: 2, 3, 4, 5, 6”

Print Darkness Range

A “range: A, B”

Print Darkness

3 “range: 1, 2, 3, 4, 5”

Start Position Offset

+0

‘0’ Font Switch Over

YES

Proportional Pitch Specification

Proportional Pitch

CL408e/412e

Item

Default Value

Print Speed

4 inch/sec(100mm/sec) “range: 2, 3, 4, 5, 6”

Print Darkness Range

A“range: A, B”(CL412e only)

Print Darkness

3“range: 1, 2, 3, 4, 5”

Start Position Offset

+0

‘0’ Font Switch Over

YES

Kanji Code Switch Over

JIS

Proportional Pitch Specification

Proportional Pitch

CL608e/612e

Item

Default Value

Print Speed

6 inch/sec(150mm/sec) “range: 4, 6, 8”

Print Darkness Range

A

Print Darkness

2 “range: 1, 2, 3”

Start Position Offset

+0

‘0’ Font Switch Over

YES

Kanji Code Switch Over

JIS

Proportional Pitch Specification

Proportional Pitch

M-84Pro-2

Item

Default Value

Print Speed

6 inch/sec(150mm/sec) “range: 2, 4, 6, 8, 10”

Print Darkness Range

A

Print Darkness

3 “range: 1, 2, 3, 4, 5”

Start Position Offset

+0

‘0’ Font Switch Over

YES

Kanji Code Switch Over

JIS

Proportional Pitch Specification

Proportional Pitch

M-84Pro-3

Item

Default Value

Print Speed

6 inch/sec(150mm/sec) “range: 2, 4, 6, 8”

Print Darkness Range

A

Print Darkness

3 “range: 1, 2, 3, 4, 5”

Start Position Offset

+0

‘0’ Font Switch Over

YES

Kanji Code Switch Over

JIS

Proportional Pitch Specification

Proportional Pitch

8

M-84Pro-6

Item

Default Value

Print Speed

3 inch/sec(75mm/sec) “range: 2, 3, 4, 5, 6”

Print Darkness Range

A “range: A, B, C”

Print Darkness

3 “range: 1, 2, 3, 4, 5”

Start Position Offset

+0

‘0’ Font Switch Over

YES

Kanji Code Switch Over

JIS

Proportional Pitch Specification

Proportional Pitch

M-8400Rve

Item

Default Value

Print Speed

6 inch/sec

(

150mm/sec

)

“range: 2, 4, 6, 8, 10”

Print Darkness Range

A

“range: A, B”

Print Darkness

3

“range: 1, 2, 3, 4, 5”

Start Position Offset

+0

‘0’ Font Switch Over

YES

Kanji Code Switch Over

JIS

Proportional Pitch Specification

Proportional Pitch

M-5900RVe

Item

Default Value

Print Speed

3 inch/sec

(

75mm/sec

)

“range: 2, 3, 4, 5, 6”

Print Darkness Range

A

Print Darkness

3 “range: 1, 2, 3, 4, 5”

Start Position Offset

+0

‘0’ Font Switch Over

YES

Kanji Code Switch Over

JIS

Proportional Pitch Specification

Proportional Pitch

M-10e

Item

Default Value

Print Speed

5 inch/sec

(

125mm/sec

)

“range: 4, 5, 6”

Print Darkness Range

A

Print Darkness

3 “range: 1, 2, 3, 4, 5”

Start Position Offset

+0

‘0’ Font Switch Over

YES

Kanji Code Switch Over

JIS

Proportional Pitch Specification

Proportional Pitch

9

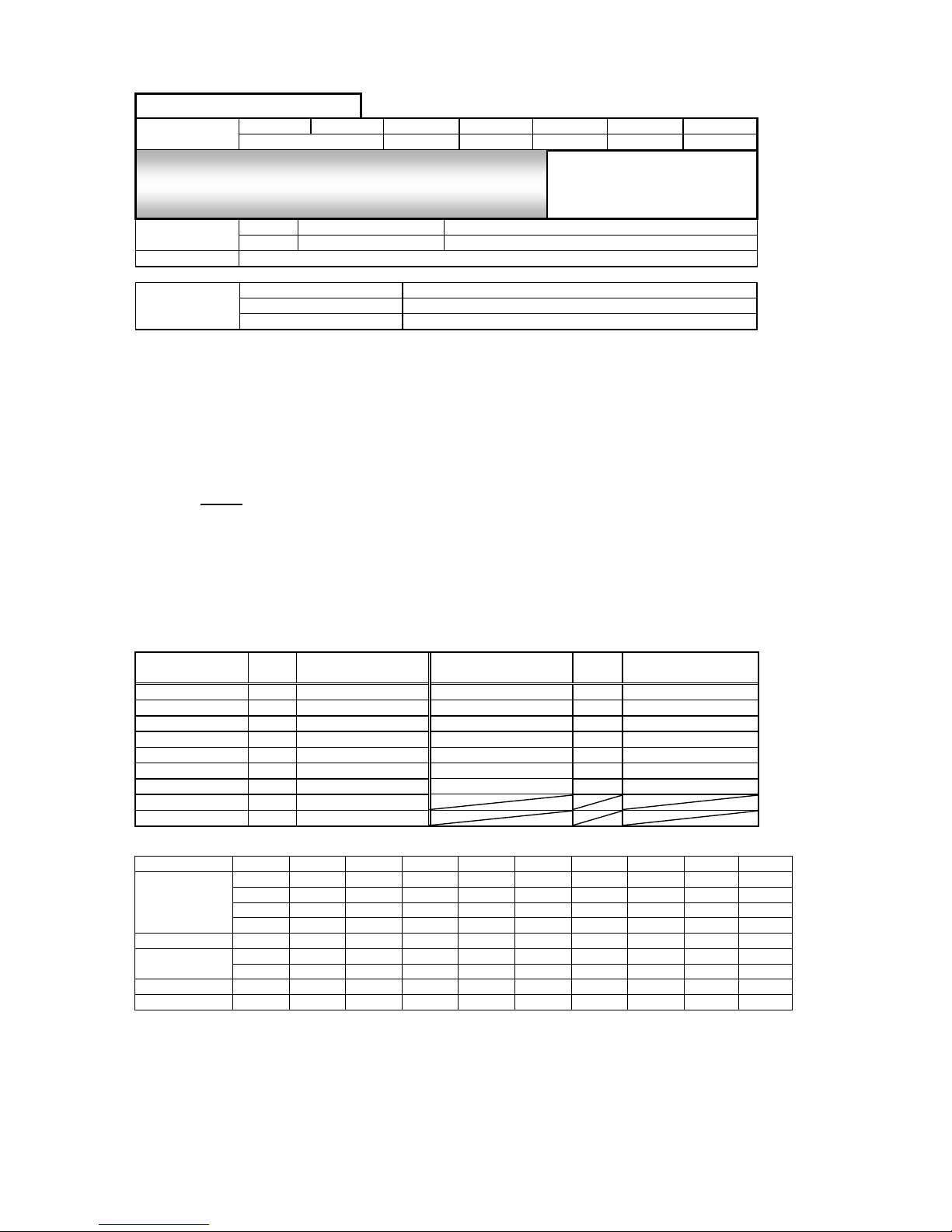

3. Font Table

When installation font is used, specify the ESC+(font type command).

Font Font Type Pitch Printer Model

OA

(

8dot/mm

)

Bit Map

「

OCR-A font

」

15×22 dot

Fixed

All Models

OB

(

8dot /mm

)

Bit Map

「

OCR-B font

」

20×24 dot

Fixed

All Models

OA

(

12dot /mm

)

Bit Map

「

OCR-A font

」

22×33 dot

Fixed

All Models

OB

(

12dot /mm

)

Bit Map

「

OCR-B font

」

30×36 dot

Fixed

All Models

OA

(

24dot /mm

)

Bit Map

「

OCR-A font

」

44×66 dot

Fixed

M-84Pro only

OB

(

24dot /mm

)

Bit Map

「

OCR-B font

」

60×72 dot

Fixed

M-84Pro only

XU

Bit Map

「

XU font

」

5× 9 dot

Fixed / Proportional

All Models

XS

Bit Map

「

XS font

」

17×17 dot

Fixed / Proportional

All Models

XM

Bit Map

「

XM font

」

24×24 dot

Fixed / Proportional

All Models

XB

Bit Map

「

XB font

」

48×48 dot

Fixed / Proportional

All Models

XL

Bit Map

「

XL font

」

48×48 dot

Fixed / Proportional

All Models

K1

Bit Map

「

K1 font

」

16×16 dot

Fixed

All Models

※

1,

※

2

K2

Bit Map

「

K2 font

」

24×24 dot

Fixed

All Models

※

1,

※

2

$ (specify shape)

$= (specify print)

Outline Font Fixed / Proportional All Models

RD

CG Font

「

CG Times

」

Fixed / Proportional

All Models

CG Font

「

CG Triumvirate

」

Fixed / Proportional

All Models

※1 Except LC400e series.

※2 The Option Kanji PCB (MEM PCB with Kanji ROM, Main PCB with Kanji ROM) is required.

10

Enlarge Font

The installation font is enlargeable from 1~12 times.

The internal bitmap is enlargeable from its standard size of 1~12 times.

For example, if the standard size is enlarged to 3 times with the width 5dot X height 9dot, it becomes at width 15dot X

height 27 dot.

Below is the parameter filling method of printed character at height X enlargement ratio, width X enlargement ratio.

width X enlargement ratio = width parameter setting value

height X enlargement ratio = height parameter setting value

Enlarge Specification <L> is controlling the font size of enlargement. The parameter is specified by the ratio.

For instance, if it is specified as <L>0304, font will be set at horizontal direction X 3 times and vertical direction X 4

times bigger than the standard size.

Character pitch is also enlarged if Expand Specification Command is specified.

Fixed Pitch and Proportional Pitch

XU~XL Font, Outline Font, CG Font can select Fixed Pitch and Proportional Pitch Printing.

Proportional Pitch Specification can be set at proportional pitch specification <PS>, proportional pitch release

specification<PR>,or printer’s LCD advance mode.

The proportional pitch size is different depends on font type. If proportional pitch is specified, the width of alphanumeric

will become smaller.

The character width of fixed pitch is based on the font size respectively.

Difference between Outline Font and Bit Map Font

Bitmap font is internally installed at a fixed font height and width size. The actual height of bitmap font is slightly bigger

than the width.

Bitmap font is the biggest size of font matrix.

The reference for font type and font size is at the previous page of Font Table.

Set the height and width of the outline font equally, a well-balanced font can be generated by using the Smooth Scaling

Argorithm Function of the printer. In addition, many font styles such as character decoration, reverse plate, shadow and

italics can be selected.

11

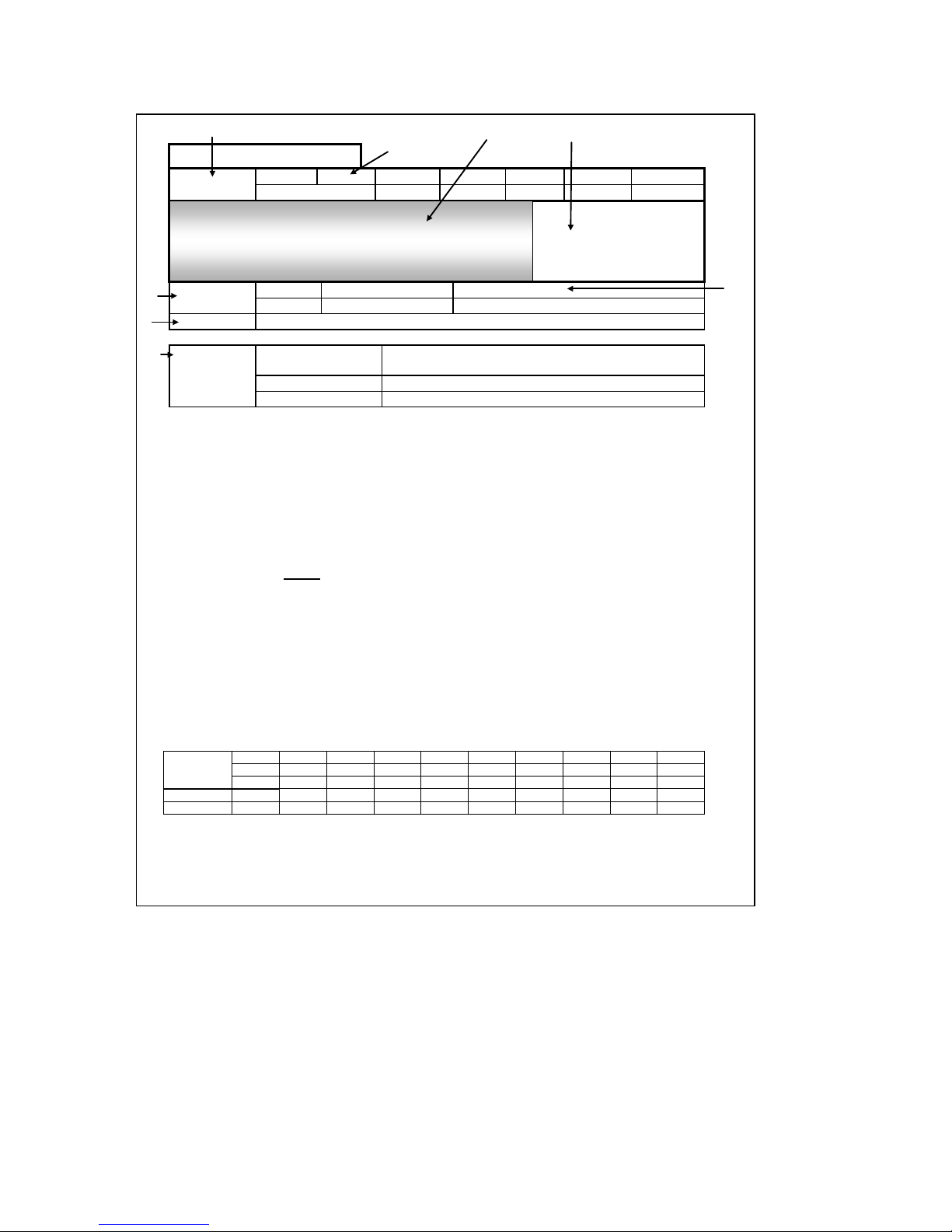

4. View Point of Command Manual

7.2 Modify

Printer

CL408e/412e

M-8400RVe

CL608e/612e

M-5900RVe

M-10e

M-8485Se/90Se/60Se/59Se

M-84Pro-2/3/6

LC408e/412e

ESC+L

HEX Code

ESC

L

Parameter

<1B>

16

<4C>

16

aabb

Default Value

aa=01, bb=01

Valid Range and

Term of

Command

When Power is Switched

Off

The set parameter. is not maintained.

Valid Range within Items

The set parameter is vlaid til it is set to the next specification

Valid Range between Items

The set parameter becomes default value at next item <A>

[Function]

To specify the enlargement ratio of print font.

[Format]

<L>aabb

● Parameter

a {Enlargement Ratio in Horizontal Direction} = Valid Range : 01~12

b {Enlargement Ratio in Vertical Direction} = Valid Range : 01~12

[Coding Example] Enlargement Ratio in Horizontal Direction:4 times, Enlargement Ratio in Vertical Direction:3 times

<A>

<V>100<H>200<P>3<L>0403<XM>ABCD

<Q>2

<Z>

[Supplementary Explanation]

1.Character pitch is enlarged at the same time. When character pitch specification <P> is used at the same time, the parameter value of horizontal

direction enlargement ratio which is specified at enlargement specification <L> will be reflected in the next character pitch specification <P>

2.To enlarge the graphic, specify the enlargement specification <L> before the graphic print command.

[Point]

1.To enlarge the ratio, design the print format which will not exceed the print area.

[Valid Command]

Font

<XU>

<XS>

<XM>

<XB>

<XL>

<X70>

*1

<X71>

*1

<X72>

*1

<X73>

*1

<X74>

*1

<X75>

*1

<X76>

*1

<X77>

*1

<OA>

<OB>

<K1>

*2

<K2>

*2

<K3>

*3

<K8>

*2

<K9>

*2

<k1>

*2

<k2>

*2

<k3>

*3

<k8>

*2

<k9>

*2

Modify

<P>

<RF>

Graphic

<G>

<GM>

<GP>

*1 Valid only for M84PRO

*2 The Optional Kanji ROM is required

*3 Valid only for CL4e/6e (Optional Kanji ROM is required)

①Show the classification of Command

It is classified in “Control”, “Print Position”, “Modify”, “Font”, “Barcode”, “2-D Code”, “Graphic”, “System”, “Memory Card”,

“Calender”.

①

③

④

⑧

⑨

⑩

⑪

⑫

⑬

⑭

②

Enlargement

⑤

⑦

⑥

12

②To identify Command Valid / Invalid for each model

When the command is invalid, it will be shown as{ }

e.g.) following table shows when the command is valid only for M-10e

Printer

CL408e/412e

M-8400RVe

CL608e/612e

M-5900RVe

M-10e

M-8485Se/90Se/60Se/59Se

M-84Pro-2/3/6

LC408e/412e

③To show command name

④To show command code

⑤To show command by HEX Code

⑥To show parameter described in the command, ()shows that “valid to omit”.

⑦To show the default value of command

⑧To show the valid range of command

●When power is switched off

(1)Set parameter will be maintained

(2)Set parameter will not be maintained

(3)Set command will not be maintained

●Valid range within Items

(1)The set parameter is valid until the next specification is made

(2)The set parameter becomes invalid

(3)The set command becomes invalid

●Valid range between Items

(1)The set parameter becomes default value at the next item <A>

(2)The set parameter becomes valid until the next specification is made

(3)The set parameter becomes invalid

(4)The set command becomes invalid.

⑨To explain the outline of command function

⑩To explain command and required parameter

<L>aabb and command of ESC+L(<1B>16<4C>16)reflects 2 types of parameter aa or bb.

⑪To explain command example

If the content of coding example is outputted from printer connected with RS-232C, the following will appear if programming is done

by BASIC language.

⑫To make supplementary explanation on command function and meaning of parameter.

⑬To explain the important point and control when command is used.

⑭To explain affected command when command is used.

10 ESC$=CHR$(&H1B)

20 OPEN “COM1:9600,N,8,1,RS,BIN” FOR OUTPUT AS #1

30 PRINT #1,ESC$;“A”;

40 PRINT #1,ESC$;“V100”;ESC$;“H200”;

50 PRINT #1,ESC$;“P3”;ESC$;“L0403”;

60 PRINT #1,ESC$;“XMABCD”;

70 PRINT #1,ESC$;“Q2”;

80 PRINT #1,ESC$;“Z”;

90 CLOSE #1

100 END

13

5. Control Command

5.1 Control

Printer

CL408e/412e

M-8400RVe

CL608e/612e

M-5900RVe

M-10e

M-8485Se/90Se/60Se/59Se M-84Pro-2/3/6 LC408e/412e

5.1 ESC+A Data Send Start ESC+A

HEX Code

ESC

A

Parameter

<1B>16

<41>16

NIL

Default Value

NIL

Valid Range and

Terms of

Command

When Power is Switched Off

The set command is not maintained

Valid Range within Items

The set command becomes invalid

Valid Range between Items

The set command becomes invalid

[Function]

To specify Data Send Start.

[Format]

<A>

[Coding Example]

<A>

<V>100<H>200<P>2<L>0202<XM>ABCD

<Q>2

<Z>

[Supplementary Explanation]

1.To show item starts, must be used at the beginning of the item.

2.Data Send Start Specification <A> and Data Send End Specification <Z> must be used as a pair.

[Point]

1.All of the command setting value excluded one portion of the system command will return to the default value.

2.Print motion is inactive when Data Send Start Specification <A> is not specified.

Data Send Start

14

5.2 Control

Printer

CL408e/412e

M-8400RVe

CL608e/612e

M-5900RVe

M-10e

M-8485Se/90Se/60Se/59Se M-84Pro-2/3/6 LC408e/412e

5.2 ESC+Z Data Send End ESC+Z

HEX Code

ESC

Z

Parameter

<1B>16

<5A>16

NIL

Default Value

NIL

Valid Range and

Terms of

Command

When Power is Switched Off

The set command is not maintained

Valid Range within Items

The set command becomes invalid

Valid Range between Items

The set command becomes invalid

[Function]

To specify Data Send End

[Format]

<Z>

[Coding Example]

<A>

<V>100<H>200<P>2<L>0202<XM>ABCD

<Q>2

<Z>

[Supplementary Explanation]

1.To show the completion of item, must be used at the end of the item.

2.Data Send Start Specification <A> and Data Send End Specification <Z> must be used as a pair.

[Point]

1.Print motion is inactive when Data Send End Specification <Z> is not specified.

Data Send End

15

5.3 Control

Printer

CL408e/412e

M-8400RVe

CL608e/612e

M-5900RVe

M-10e

M-8485Se/90Se/60Se/59Se M-84Pro-2/3/6 LC408e/412e

5.3 ESC+Q Print Number ESC+Q

HEX Code

ESC

Q

Parameter

<1B>16

<51>16

aaaaaa

Default Value

aaaaaa=1

Valid Range and

Terms of

Command

When Power is Switched Off

The set parameter is not maintained

Valid Range within Items

The set parameter becomes invalid

Valid Range between Items

The set parameter becomes invalid

[Function]

To specify number of printing

[Format]

<Q>aaaaaa

●Parameter

a {Number to print} = Valid Range : 1~999999

[Coding Example] Print Number Specification:2 pieces

<A>

<V>100<H>200<P>2<L>0202<XM>ABCD

<Q>2

<Z>

[Supplementary Explanation]

1.As 1 print content that is specified by Data Send Start Specification <A> ~ Data Send End Specification <Z>, several same content

printing will be specified.

2.Must be used before data send complete specification <Z>.

[Point]

1.Number of printing is specified, even if same label is printed, if Sequential Number Specification <F> is used, only the sequential

number value set at the field portion will be printed out.

2.If it is combined with Multiple Cut Specification <~>, print numbers is printed out by calculation from print number times cut specified

value.

Print Number

16

5.4 Control

Printer

CL408e/412e

M-8400RVe

CL608e/612e

M-5900RVe

M-10e

M-8485Se/90Se/60Se/59Se M-84Pro-2/3/6 LC408e/412e

5.4 ESC+ID Job ID Number ESC+ID

HEX Code

ESC

ID

Parameter

<1B>16

<49>16<44>16

aa

Default Value

aa=<20>16

Valid Range and

Terms of

Command

When Power is Switched Off

The set parameter is not maintained

Valid Range within Items

The set parameter is valid until the next specification is made

Valid Range between Items

The set parameter becomes invalid

[Function]

To specify Job ID No for status send

[Format]

<ID>aa

●Parameter

a {Job ID No} = Valid Range : 00~99

[Coding Example] Job ID No:01

<A>

<ID>01

<V>200<H>100<P>0<$>B,100,100,6

<$=>SATOPRINTER

<Q>2

<Z>

[Supplementary Explanation]

1.When status return is used on interface protocol, the specified Job ID No can be set at the telegraphic status.

2.Status can be confirmed by sending status request (ENQ).

3.Program it within items and use it whle printing is performed by Data Send Start Specification <A> ~ Data Send End Specification

<Z>.

[Point]

1.Status return interface protocol is valid when status request (ENQ) during printing(QTY≠0, includes when Offline and Error occurs) is

received.

2.At the status return interface protocol, if status request (ENQ) is returned not during printing, (QTY=0, no received data when power

is switched on), set a space (20H) at the status and then return it.

3.Within items of Data Send Start Specification<A> ~ Data Send Complete Specification <Z>, the final specified value is valid when

Job ID Number Specification <ID> is used more than twice.

4.The details can be referred to “Interface Specification”

Job ID Number

17

5.5 Control

Printer

CL408e/412e

M-8400RVe

CL608e/612e

M-5900RVe

M-10e

M-8485Se/90Se/60Se/59Se M-84Pro-2/3/6 LC408e/412e

5.5 ESC+WK Job Name ESC+WK

HEX Code

ESC

WK

Parameter

<1B>16

<57>16<4B>16

aaaaaaaaaaaaaaaa

Default Value

aaaaaaaaaaaaaaaa=<20>16

Valid Range and

Terms of

Command

When Power is Switched Off

The set parameter is not maintained

Valid Range within Items

The set parameter becomes valid until the next specification is

made

Valid Range between Items

The set parameter becomes invalid

[Function]

To specify Job Name for status return

[Format]

<WK>aaaaaaaaaaaaaaaa

●Parameter

a {Job Name} = ASCII Code 16 digits, shift JIS Kanji 8 digits

[Coding Example] Job Name:SATO

<A>

<WK>SATO

<V>200<H>100<P>0<$>B,100,100,6

<$=>SATOPRINTER

<Q>2

<Z>

[Supplementary Explanation]

1.If status 4 is used on interface protocol, the specified Job Name can be set at the telegraphic status.

2.Confirm the status at every ouput of status request (ENQ)

3.Program it within items and use it while printing is performed by using Data Send Start Specification <A> ~ Data Send Complete

Specification <Z>.

4.Can be used by combining with Job ID No Specification <ID>.

[Point]

1.At the status return interface protocol , it is valid if status request (ENQ) is received during printing (QTY≠0, includes Offline,

error).

2.At the status return interface protocol, if status request (ENQ) is received not during printing (QTY=0, received data is not

available

when power is switched on), set the space (20H) at the status and then return it.

3.Within the Data Send Start Specification <A> ~ Data Send Complete Specification <Z>, the final specified value becomes valid

when Job Name Specification <WK> is used more than twice.

4.The details can be referred to the “Interface Specification”.

Job Name

18

5.6 Control

Printer

CL408e/412e

M-8400RVe

CL608e/612e

M-5900RVe

M-10e

M-8485Se/90Se/60Se/59Se M-84Pro-2/3/6 LC408e/412e

5.6 ESC+RK RFID Write ESC+RK

HEX Code

ESC

RK

Parameter

<1B>16

<52>16<4B>16

a(,b)(,c),Dmm,n~n

Default Value

b=0, c=0

Valid Range and

Terms of

Command

When Power is Switched Off

The set parameter is not maintained

Valid Range within Items

The set parameter becomes invalid

Valid Range between Items

The set parameter becomes invalid

[Function]

To specify data to be written in RFID Tag

[Format]

<RK>a(,b)(,c),Dmm,n~n

●Parameter

a {Tag Type Specification} = 0 : I-CODE(max 48 byte writable)

1 : TAG-IT (max 32 byte writable)

b {RFID Tag Error Ignore Specification}omittable = 0 : No Specification when omission 0

1 : With Specification

2~9 : RFID Tag Error Ignore Specification Print Number

c {Write Protector Specifcation}omittable = 0 : No Specification when omission 0

1 : With Specification(valid only when a=1)

m {Write Data Size Specification} = valid range : 0~48(byte)(when it is a=1)

: 0~32(byte)(when it is a=2)

n {Write Data}

[Coding Example 1] Record 13 byte of characters {4912345678904}on the Ta g -it tag(omit b,c)

<A>

<V>50<H>50<BD>3020654912345678904

<RK>1,D13,4912345678904

<Q>2

<Z>

[Coding Example 2] Record 13 byte of characters {4912345678904}on the Tag-it tag, ignore 3 pieces of errors(omit c)

<A>

<V>50<H>50<BD>3020654912345678904

<RK>1,3,D13,4912345678904

<Q>2

<Z>

[Coding 3] Record 13 byte of characters {4912345678904}on the Tag-it tag, error ignore is not available, write protector is available.

<A>

<V>50<H>50<BD>3020654912345678904

<RK>1,0,1,D13,4912345678904

<Q>2

<Z>

RFID Write

19

[Supplementary Explanation]

1.Valid only with Optional installed model of CL408e/412eRFID.

2.RFID Write Specification <RK> operates as printer’s print motion, the following motions of Continuous Motion, Cutter Motion, (Motion

1), Dispense Motion (Motion 1) and Tear Off Motion is applicable. However, if tear off motion is specified, information return

becomes invalid even if it is writable to the tag.

3. RFID Write Specification <RK> cannot be specified at multiple between Data Send Start Specification <A> ~ Data Send Complete

Specification <Z>. Use STX+<A> and <Z>+ETX as a pair. The motion is not stable when STX and ETX is omitted.

4.When RFID Tag Error Ignore is specified, print job will be re-started automatically when RFID Tag Error occur. After the re-start, the

data as same as the sent-data will be sent when RFID Tag Error occur, the quantity specified at Print Label Specification <Q> will

not be deducted.

When RFID Tag Error Ignore Specification is set at 2~9, the specified quantity of RFID Tag Error will be ignored. If specified

quantity of RFID Tag Error continue to appear, print job will be stopped with error. To stop auto printing temporarily when RFID tag

error occurs, press LINE key when RFID TAG ERROR is displaying on the LCD screen, set to Offline status, clear all of the

received data.

5.If specification of parameter b is omitted, RFID Tag Error Ignore Specification will not be performed.

6.Once specification of parameter c is omitted, write protector specification will not be executed. If specification of parameter b is

omitted, the specification of parameter c is not able to be performed.

7.If write protector is specified, data which is written to the Tag will be protected. Please be noted that once the Tag is protected, the

re-write of the Tag is not able to be executed. And if data re-write is performed by printer to the protected Tag data, RFID Tag Error

will appear.

8.Only TAG-IT can be applied on Write Protector Specification. If write protector is specified against I-CODE tag, command error will

appear.

9.Information of sequential and calendar cannot be written in RFID. It can be used with combination with Job ID Specification <ID>.

10. The RFID detail motion can be referred to “RFID Kit Option Specification”.

20

6. Print Position Command

6.1 Print Position

Printer

CL408e/412e

M-8400RVe

CL608e/612e

M-5900RVe

M-10e

M-8485Se/90Se/60Se/59Se M-84Pro-2/3/6 LC408e/412e

6.1 ESC+H Print Horizontal Position ESC+H

HEX Code

ESC

H

Parameter

<1B>16

<48>16

aaaa

Default Value

aaaa=1

Valid Range and

Terms of

Command

When Power is Switched Off

The set parameter is not maintained

Valid Range within Items

The set parameter is valid until the next parameter is made

Valid Range between Items

The set parameter becomes default value at next item <A>

[Function]

To specify the horizontal direction print position from the print start position by dot

[Format]

<H>aaaa

●Parameter

a {Print Horizontal Position Specification} = Valid Range: refer to the table below

[Coding Example] Print Horizontal Position:200 dot

<A>

<V>100<H>200<P>2<L>0202<XM>ABCD

<Q>2

<Z>

[Supplementary Explanation]

1.To specify the start horizontal position for character, barcode, borders, graphic etc.

[Point]

1.Content (character, barcode, graphic etc) exceeds print valid range will not be printed.

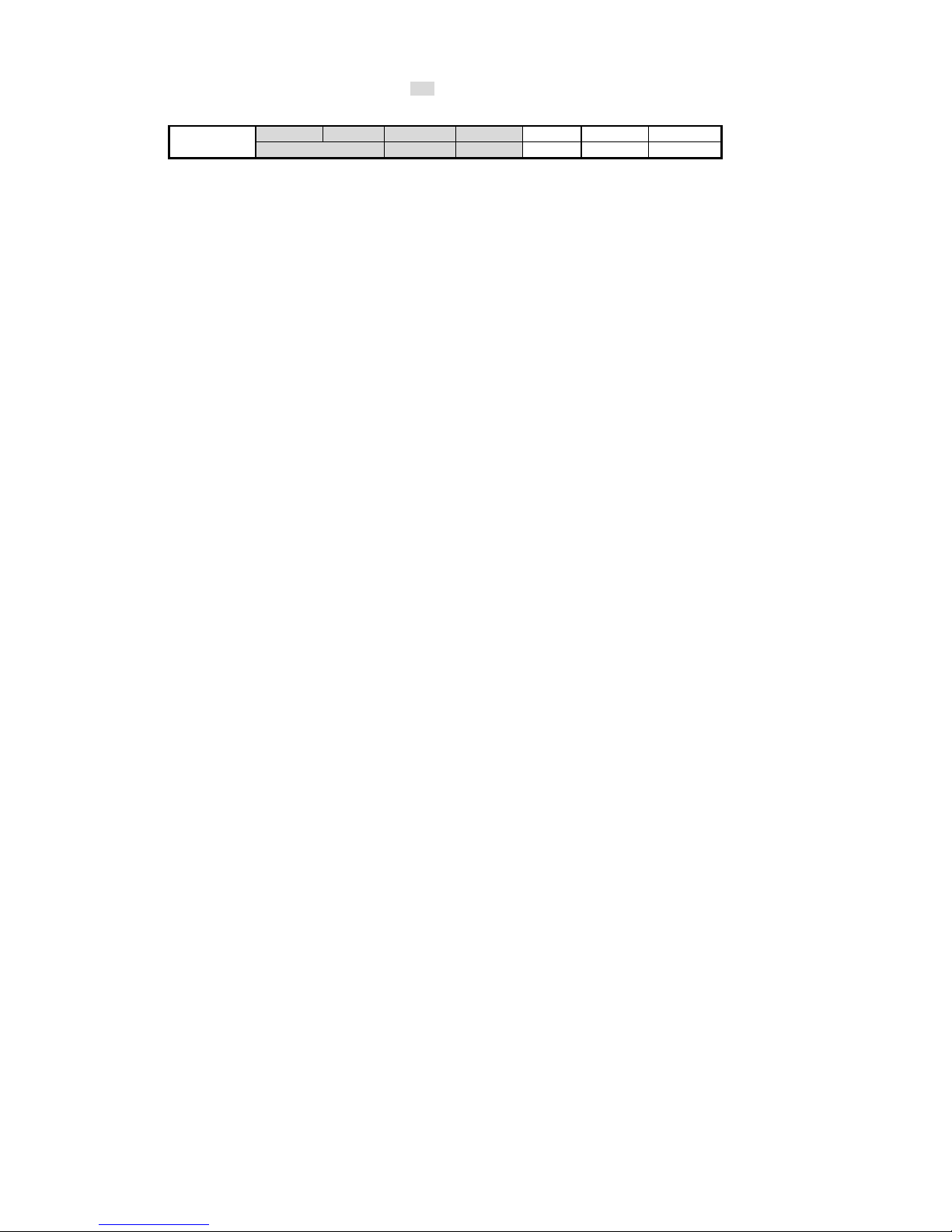

[Parameter Default Value and Valid Range]

Model Default

Value

Valid Range (dot) Model Default

Value

Valid Range (dot)

LC408e

1

1

~

832

LC412e

1

1

~

1248

CL408e

1

1

~

832

CL412e

1

1

~

1248

M-8400RVe

1

1

~

832

CL612e

1

1

~

1984

CL608e

1

1

~

1216

M-5900RVe

1

1

~

896

M-8490Se

1

1

~

1344

M-8485Se

1

1

~

1024

M-84Pro-3

1

1

~

1248

M-8460Se

1

1

~

1216

M-84Pro-6

1

1

~

2496

M-8459Se

1

1

~

896

M-84Pro-2

1

1

~

832

[Valid Command]

Modify

<WD>

<FW>

<(>

<RF>

Font

<XU>

<XS>

<XM>

<XB>

<XL>

<OA>

<OB>

<RD>

<$=>

<K1>

*1

<K2>

*1

<K8>

*1

<K9>

*1

<k1>

*1

<k2>

*1

<k8>

*1

<k9>

*1

Barcode

<B>

<BC>

<BG>

<BI>

<BP>

<D>

<D><d>

<BD>

<BT>

<BW>

2-D Code

<BK>

*2

<BQ>

*2

<BV>

*2

<BX>

*2

<2D10>

*3

<2D12>

*3

<2D20>

*3

<2D30>

*3

<2D31>

*3

<2D32>

*3

<2D50>

*3

<2D51>

*3

Graphic

<G>

<GM>

<GP>

Memory Card

<GR>

<GC>

<PY>

*1 Requires optional Kanji ROM. (Not supported for LC408e/412e.)

*2 Not supported for LC408e/412e.

*3 Supported for LC408e/412e only.

Print Horizontal Position

Other manuals for LC400e Series

1

This manual suits for next models

17

Table of contents

Other SATO Printer manuals