CJ X467-CJ X468-BA-e-2010.docx 7

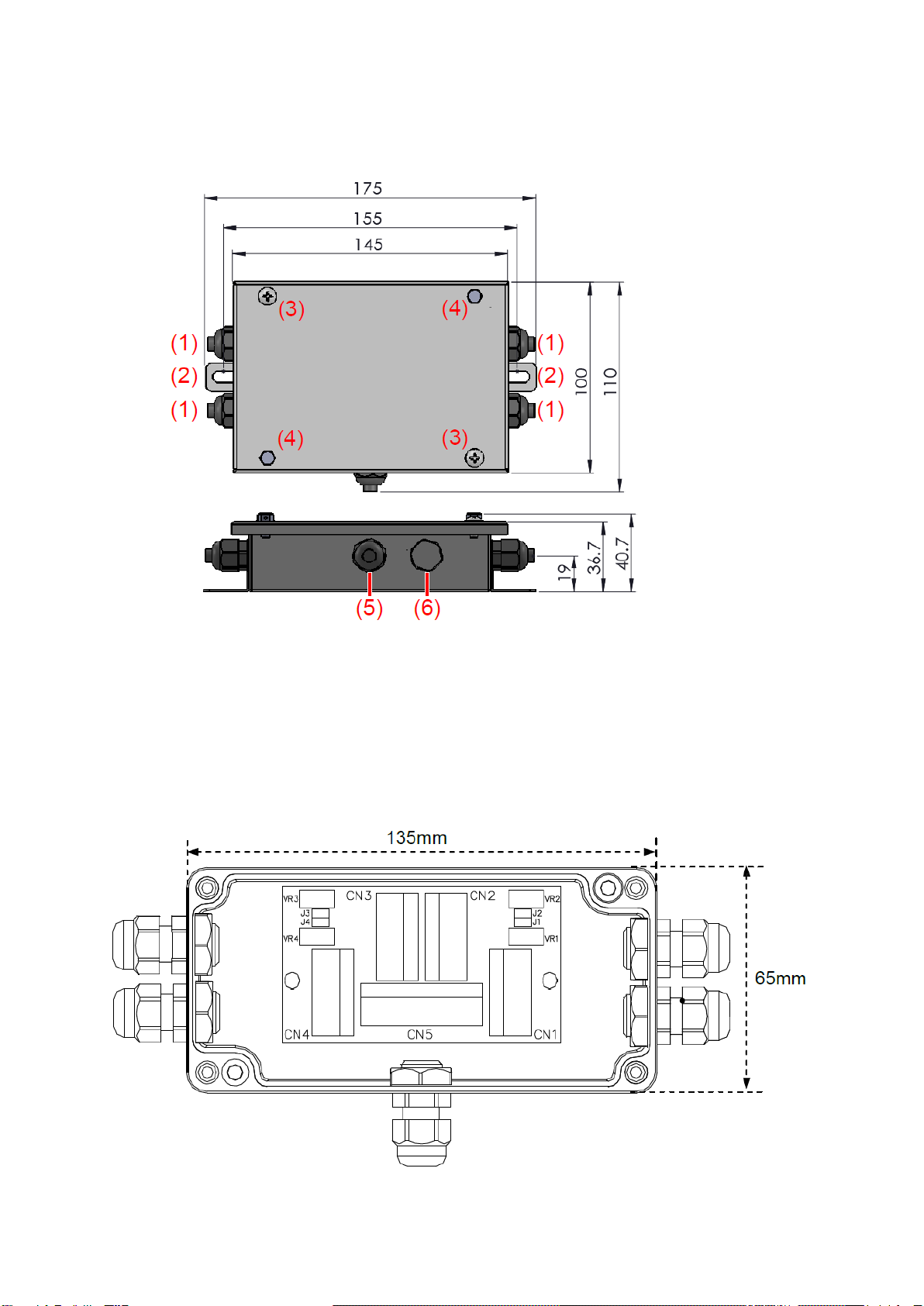

7.1 Corner adjustment

Before starting the calibration, make sure that all four jumpers are removed from J1,

J2, J3 and J4 and that all trimpots are set so that they do not affect the corner load.

This is achieved by turning the potentiometers VR1 (T1), VR2 (T2), VR3 (T3) and VR4

(T4) at least 20 turns clockwise or counterclockwise or until the end stop, which can

be signaled by a click sound.

If the trimpots VR1 (T1) and VR2 (T2) are turned clockwise and the potentiometers

VR3 (T3) and VR4 (T4) are turned counterclockwise, they reduce the load cell

performance. Place the corner load at all four corners one after the other and note the

highest measured value. Turn the corresponding trim pot to reduce the highest

measured value until it matches the lowest corner. (VR1 [T1] for load cell 1, VR2 [T2]

for load cell 2, VR3 [T3] for load cell 3 & VR4 [T4] for load cell 4)

Repeat the setting for the other corners as needed until all corners have the same

weight when the corner load is applied.

8 Small troubleshooting

8.1 The scale seems to indicate an incorrect weight

1. Unload the scale and check if the scale returns to zero.

2. Make sure that the object to be weighed is completely on the scale and is not

supported elsewhere.

8.2 The corners indicate unequal weights

1. Repeat the adjustment and the corner calibration (Chapter Fehler!

Verweisquelle konnte nicht gefunden werden.and 7.1)

2. Check the load cells for damage

8.3 The displayed value drifts quickly

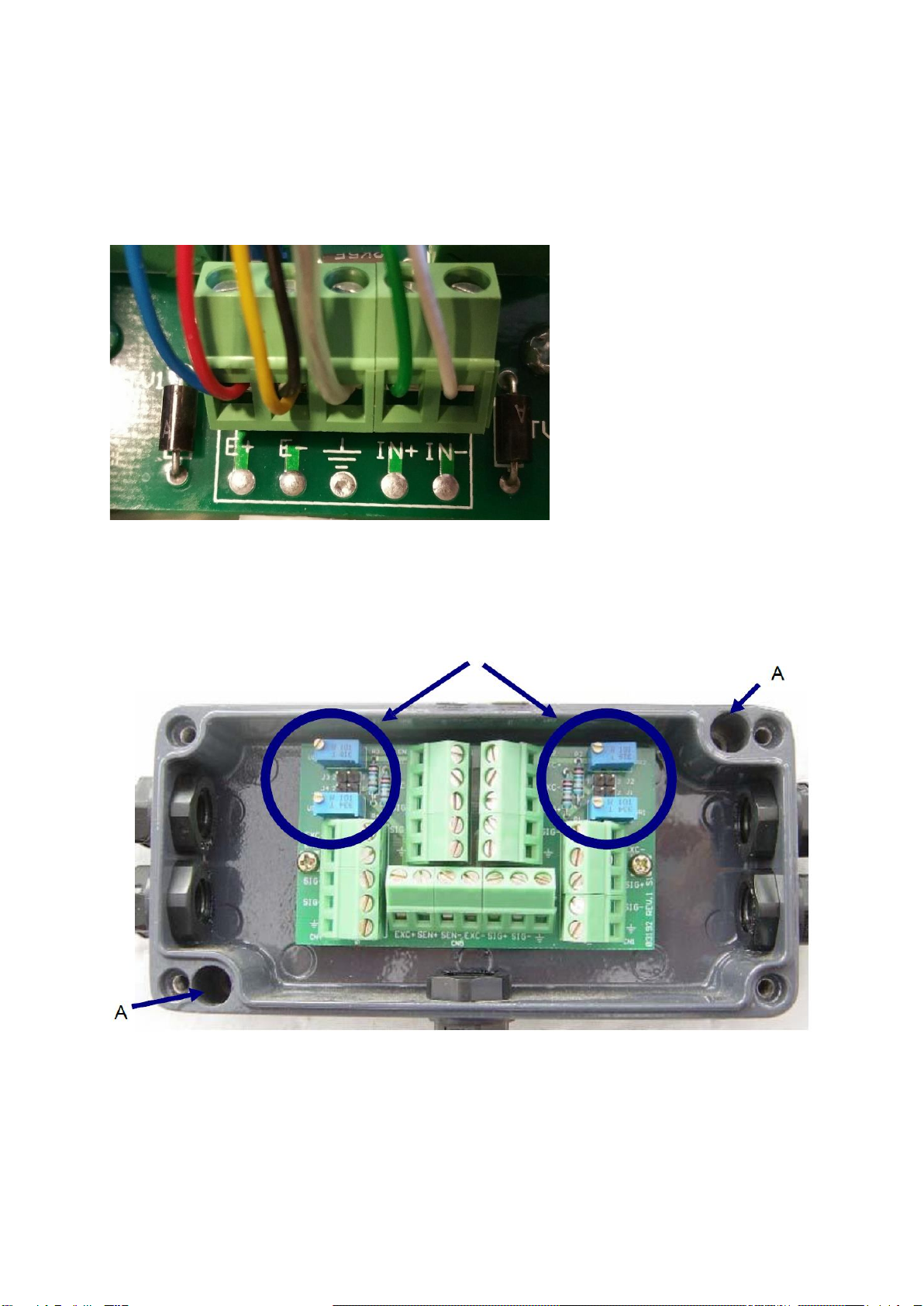

1. Check that there is no water and dirt in the box.

2. Check the load cells and cables for damage.

3. Remove one load cell at a time from the box and, if necessary, carry out a cross-

exchange to locate a defective cell.

Use a load cell simulator to check if the evaluation unit works without errors and

displays stable values.

9 Declaration of conformity

To view the CE declaration, please click on the following link:

https://www.kern-sohn.com/shop/de/DOWNLOADS/