Congratulations on the purchase of a multimode ultrasonic thickness gauge from

SAUTER. We wish you much pleasure with your quality measuring instrument with a

high functional range. For any questions, requests and suggestions, please contact

our customer service by telephone.

Table of contents:

1General information....................................................................................... 4

1.1 Product specification............................................................................................................... 4

1.2 Measuring principle.................................................................................................................. 4

1.3 Converters: technical data ...................................................................................................... 4

1.4 Configuration............................................................................................................................ 6

1.5 Working conditions:................................................................................................................. 6

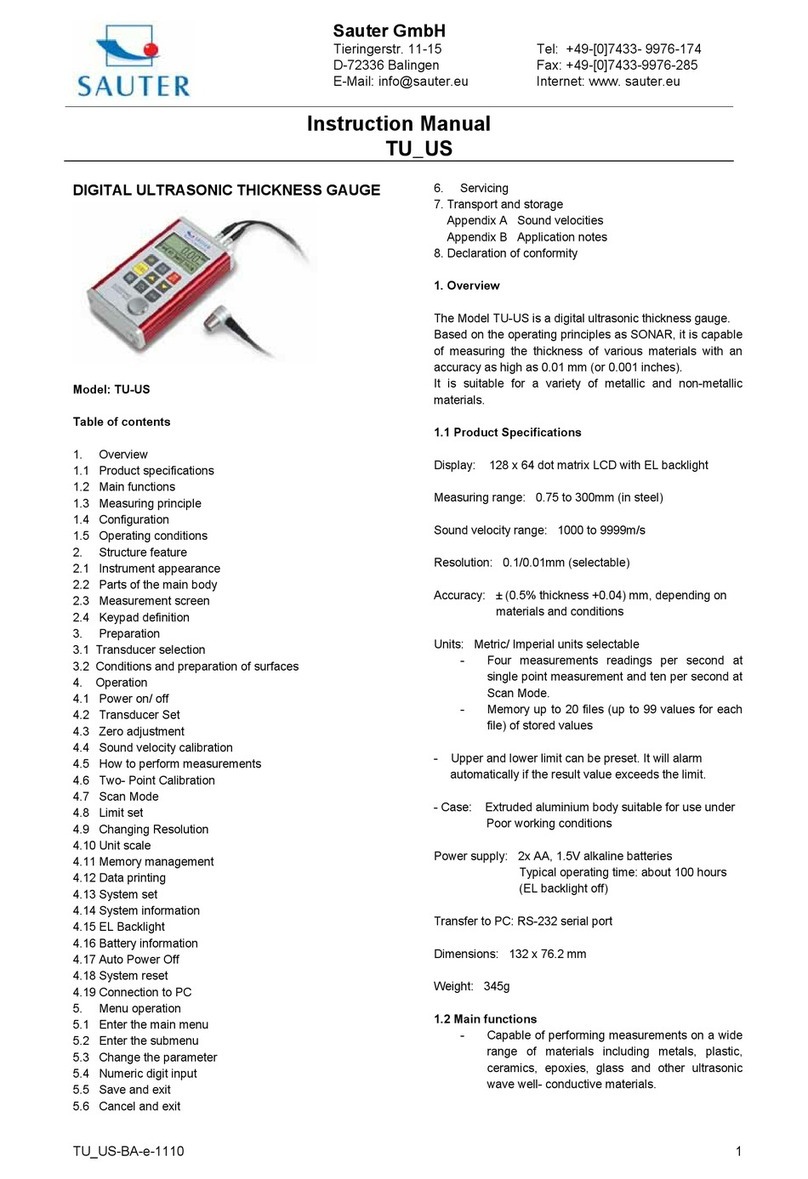

2Keypad and display....................................................................................... 6

2.1 Main screen............................................................................................................................... 7

2.2 Control panel ............................................................................................................................ 8

3Preparation for measurement....................................................................... 8

3.1 Selection of the converter ....................................................................................................... 8

3.2 Condition and preparation of surfaces ................................................................................ 10

4Operation...................................................................................................... 11

4.1 Power supply .......................................................................................................................... 11

4.2 Connecting the probe ............................................................................................................ 11

4.3 Switching on the device (Power ON).................................................................................... 11

4.4 Configuration of the standby settings ................................................................................. 12

5Operation...................................................................................................... 13

5.1 Setting the working mode ..................................................................................................... 13

5.2 Selection of the probe............................................................................................................ 13

5.3 Function "Probe Zero............................................................................................................. 13

5.4 Calibration of the sound velocity.......................................................................................... 14

5.5 Performing measurements.................................................................................................... 17

5.6 Set View Mode ........................................................................................................................ 18

5.7 Set normal thickness ............................................................................................................. 19

5.8 Set limit value ......................................................................................................................... 20

5.9 Setting the resolution............................................................................................................. 20

5.10 Memory Management............................................................................................................. 21

5.11 Setting the key tone ............................................................................................................... 23

5.12 Set warning tone..................................................................................................................... 23

5.13 Set LCD brightness level....................................................................................................... 23

5.14 Setting the display readiness................................................................................................ 23

5.15 Setting automatic switch-off ................................................................................................. 24

5.16 Change system of units......................................................................................................... 24