3 4

SAFETY INSTRUCTIONS & OPERATION

INSPECTION:

1. Before each use a visual inspection of the jack should be made. This should

check for things such as cracks in the welds, leaking oil, any general damage, and

loose or missing parts.

2. An annual inspection of the jack is recommended.

3. Do not use if any damage evident.

CAUTION BEFORE USE:

Lubricate all pivoting and moving points - see LUBRICATION on Page 5.

Occasionally during shipment and/or handling, air can become trapped in the

hydraulic system.

This can interfere with the jacks lifting performance. To alleviate this problem:

1. Ensure the jack is in lowered position. Open the release valve by turning the jack

handle anti-clockwise.

2. Rapidly pump the jack handle several times.

3. Open the air vent by removing the filler plug on the oil chamber.

4. Replace the filler plug. This process may need to be repeated several times to

purge all air out of the hydraulic system.

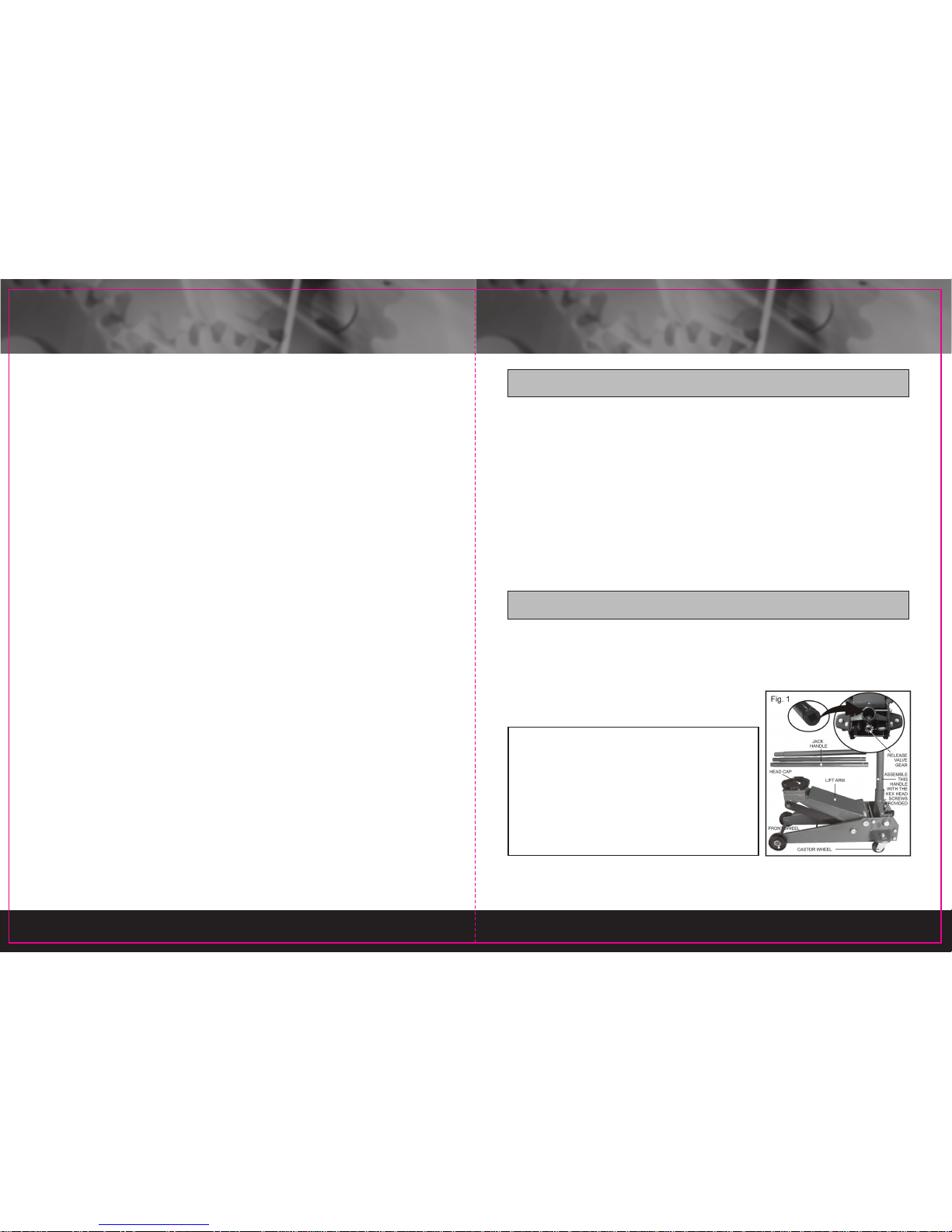

TO RAISE THE JACK:

1. Close the release valve by turning the jack handle clockwise until the release

valve is closed. Do not over tighten the valve.

2. Chock the wheels of the car with appropriate devices (e.g. Automotive wheel

chocks). This will help ensure that the vehicle will remain stable during lifting.

3. Place the jack so the head cap on the lifting arm is directly under the object to

be lifted. Please refer to the vehicle manufacturer owner’s manual to locate

approved lifting points on the vehicle.

4. Pump the jack handle until the head cap is almost in contact with the vehicle.

Check that the head cap will be centrally located at the vehicle manufacturers

recommended lifting point.

5. Continue to pump the jack handle to lift the vehicle to the desired height.

6. After lifting the vehicle to the desired height, support the load with approved

vehicle support stands before working under the vehicle.

TO LOWER THE JACK:

1. With the jack supporting the weight of the vehicle, remove the vehicle support

stands.

2. Very slowly turn the jack handle anti-clockwise.

This will open the release valve and when the release valve starts to open, the

lifting arm will lower.

3. The speed which the jack will lower, will be dependent on how rapidly the valve is

opened.

The greater it is opened the faster the jack will lower.

CAUTION:

Ensure all hands, feet and all other items are well clear of the ground area when

lowering the load.

MAINTENANCE

OIL TYPE:

IMPORTANT: When adding or replacing oil, always use a good grade of HYDRAU-

LIC FLUID. (Recommended ISO VG32, SAE10 or equivalent) Avoid mixing types of

fluid. DO NOT use Brake Fluid, Alcohol, Glycerine, Detergent, Motor Oil or Dirty Oil.

ADDING OIL & OIL LEVEL:

1. Set the jack in a horizontal level position and fully lower the head cap. Remove

the screw-in filler plug on the oil chamber (Fig. 2).

2. Fill using oil can with a fine spout. The recommended oil capacity is

approximately 190ml. If low, add oil as required.

3. Replace the screw-in filler plug on the oil chamber.