7

3.0 Safety

NB! We recommend that installation be carried out by a

qualified installer, to ensure that the product delivers maximum

performance and safety.

Any modifications to the product by the distributor, installer

or consumer may result in the product and safety features not

functioning as intended. The same applies to the installation

of accessories or optional extras that are not supplied by the

fireplace manufacturer. This may also be the case if parts that

are essential to the functioning and safety of the fireplace

have been disassembled or removed. In all these cases, the

manufacturer is not responsible or liable for the product and

the warranty shall become null and void.

The Clean Air Act

“The Clean Air Act 1993 and Smoke Control Areas”

Under the Clean Air Act local authorities may declare the

whole or part of the district of the authority to be a smoke

control area. It is an offence to emit smoke from a chimney of

a building, from a furnace or from any fixed boiler if located in a

designated smoke control area. It is also an offence to acquire

an “unauthorised fuel” for use within a smoke control area

unless it is used in an “exempt” appliance (“exempted” from

the controls which generally apply in the smoke control area).

The Secretary of State for Environment, Food and Rural

Affairs has powers under the Act to authorise smokeless

fuels or exempt appliances for use in smoke control areas in

England. In Scotland and Wales this power rests with Ministers

in the devolved administrations for those countries. Separate

legislation, the Clean Air (Northern Ireland) Order 1981,

applies in Northern Ireland. Therefore it is a requirement that

fuels burnt or obtained for use in smoke control areas have

been “authorised” in Regulations and that appliances used to

burn solid fuel in those areas (other than “authorised” fuels)

have been exempted by an Order made and signed by the

Secretary of State or Minister in the devolved administrations.

Further information on the requirements of the Clean Air Act

can be found here : http://smokecontrol.defra.gov.uk/

Your local authority is responsible for implementing the Clean

Air Act 1993 including designation and supervision of smoke

control areas and you can contact them for details of CleanAir

Act requirements”.

Your local authority is responsible for implementing the Clean

Air Act 1993 including designation and supervision of smoke

control areas and you can contact them for details of CleanAir

Act requirements”

3.1 Fire Prevention Measures

• There is a certain element of danger every time you use

your fireplace. The following instructions must therefore be

followed:

• The minimum safety distances when installing and using the

fireplace are given in fig. 1.

• Ensure that furniture and other flammable materials are not

too close to the fireplace. Flammable materials should not be

placed within 850mm of the fireplace.

• Allow the fire to burn out. Never extinguish the flames with

water.

• The fireplace becomes hot when lit and may cause burns if

touched.

• Only remove ash when the fireplace is cold. Ash can

contain hot embers and should therefore be placed in a

non-flammable container.

• Ash should be placed outdoors or be emptied in a place

where it will not present a potential fire hazard.

In case of chimney fire:

• Close all hatches and vents.

• Keep the firebox door closed.

• Check the loft and cellar for smoke.

• Call the fire service.

• Before use after a fire an expert must check the fireplace

and the chimney in order to ensure that it is fully functional.

4.0 Installation

N.B. Check that the fireplace is free of any damage prior to

commencing installation.

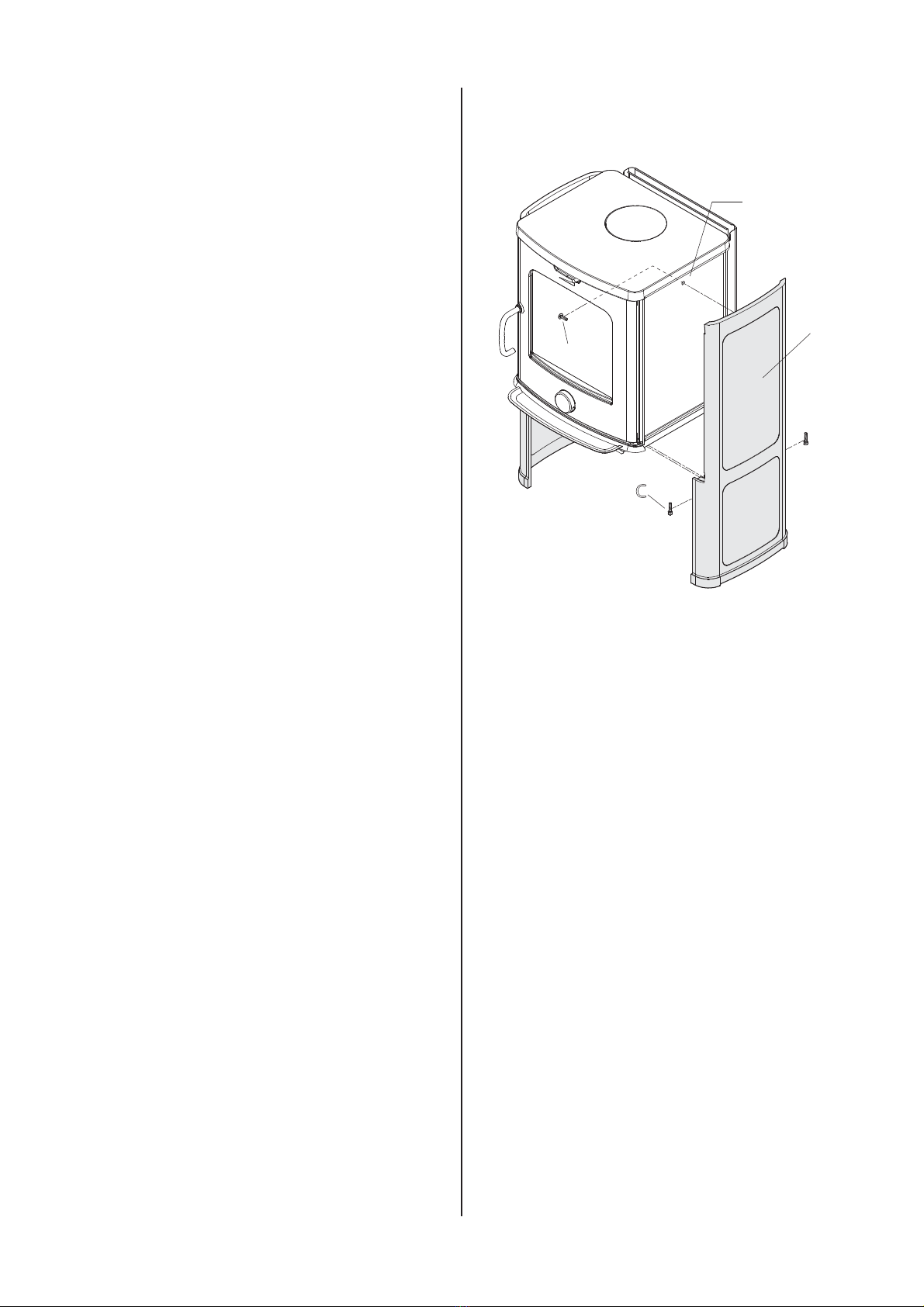

The product is heavy! Make sure you have assistance when

erecting and installing the fireplace.

4.1 Floor

Foundation

Youneedtomakesurethe foundationissuitablefora fireplace.

See “2.0 Technical Data” for specified weight.

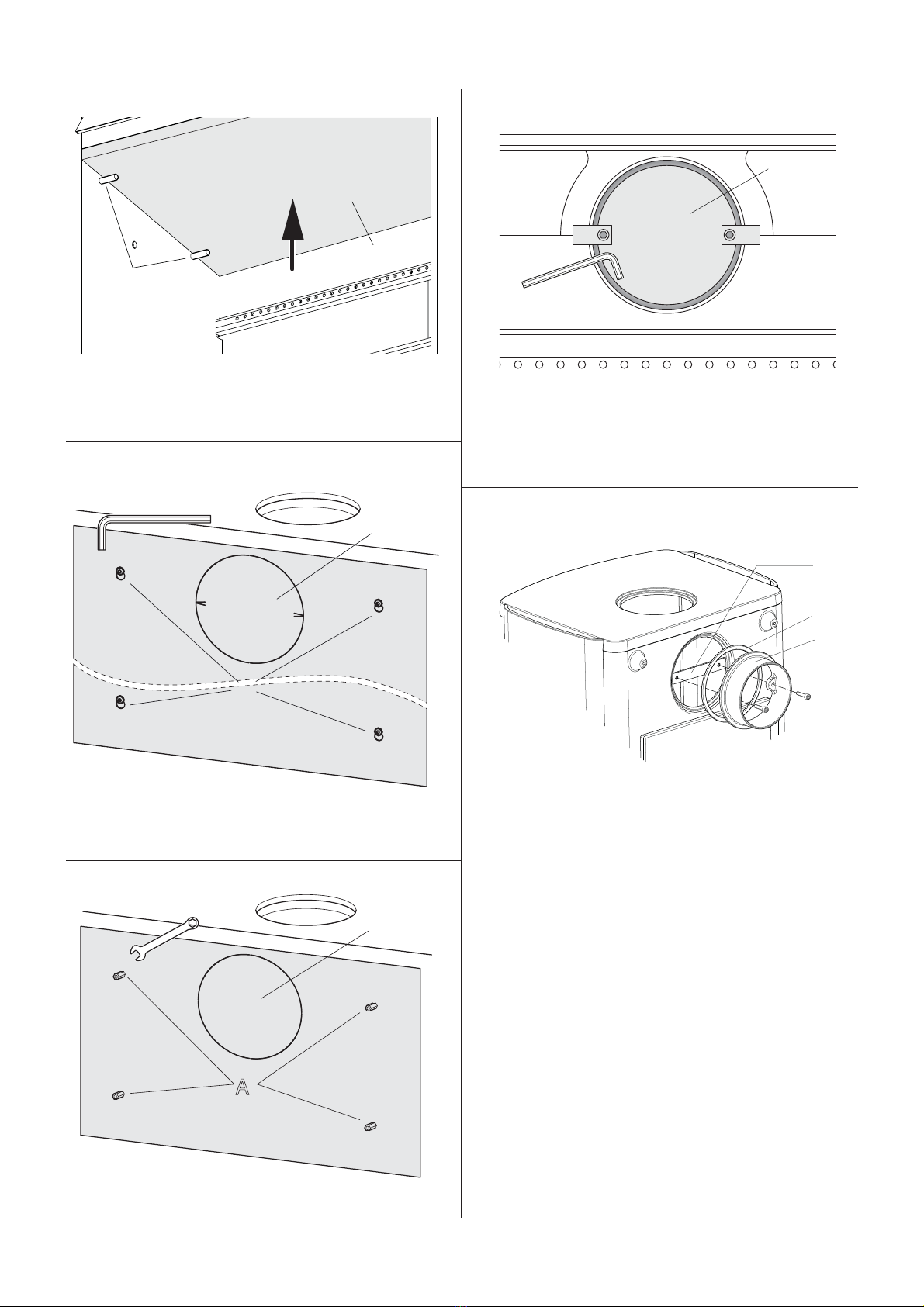

Combustible floor protection

If the fireplace is to be mounted on a combustible floor, cover

the floor under and in front of the fireplace with a plate made of

metal or other non-combustible material. The recommended

minimum thickness is 0,9 mm (fig. 1a).

Any flooring made of combustible material, such as linoleum,

carpets, etc. must be removed from under the floor plate.

Requirement for protecting combustible flooring in front of

fireplace

The front plate must be in accordance with national laws and

regulations.

Contact your local building authorities regarding restrictions

and installation requirements.

4.2 Wall

Minimum distance to combustible wall

For distance to combustiblewall see fig. 1b.

Minimum distance to incumbent

firewall

For distance to incumbent firewall see fig. 1c.

Firewall requirement

The firewall must be at least 100 mm thick and be made of

brick, concrete-stone or light concrete. Other materials and

constructions with satisfactory documentation may also be

used.

English