#Bio25 11 – 140813 Page 3 of 40

Contents

1. Introduction.................................................................................................. 4

2. Safety Instructions ........................................................................................ 5

3. General Description...................................................................................... 6

4. Technical Data .............................................................................................. 7

4.1. Specifications..................................................................................................7

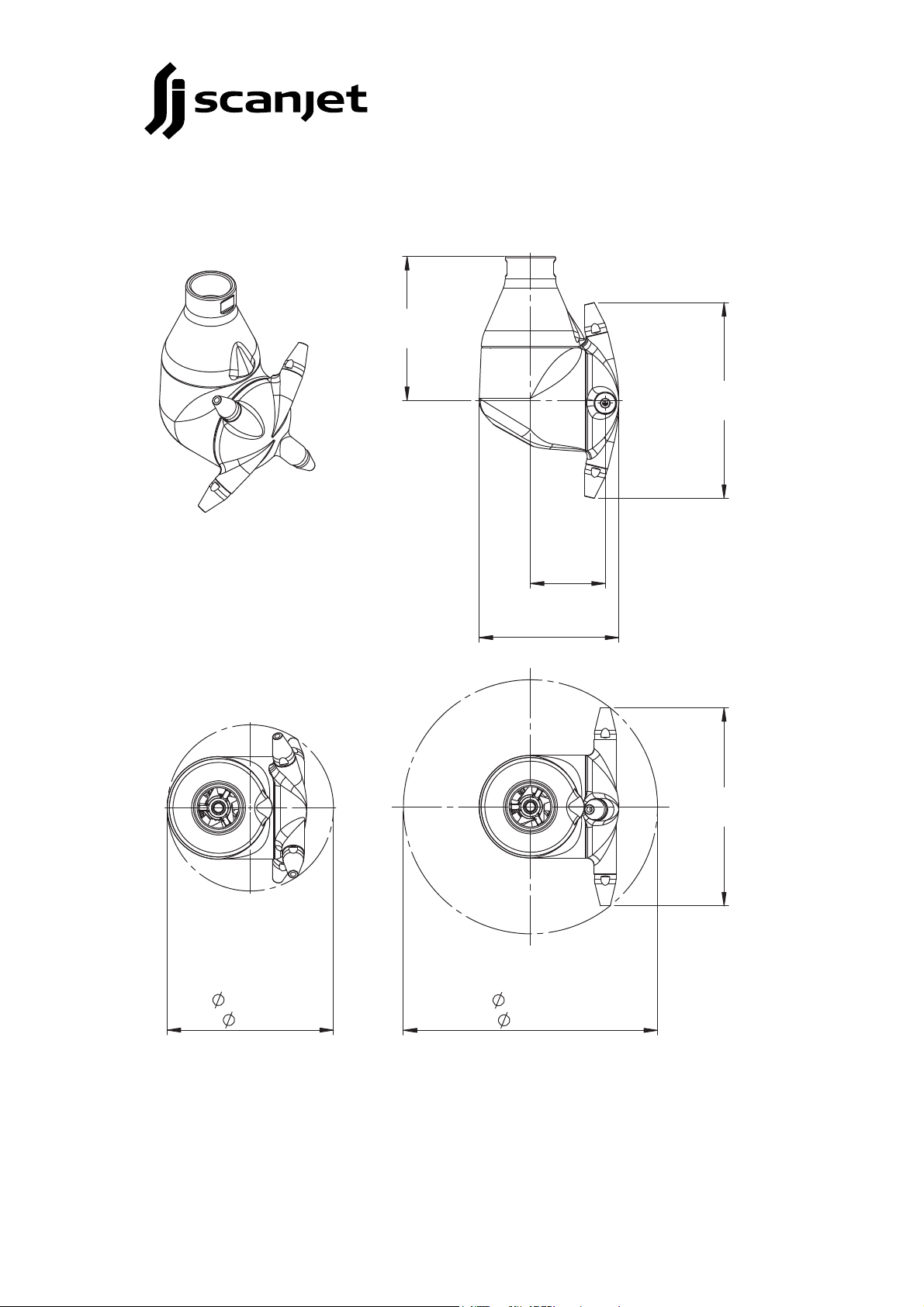

4.2. Dimensions BIO 25 .........................................................................................8

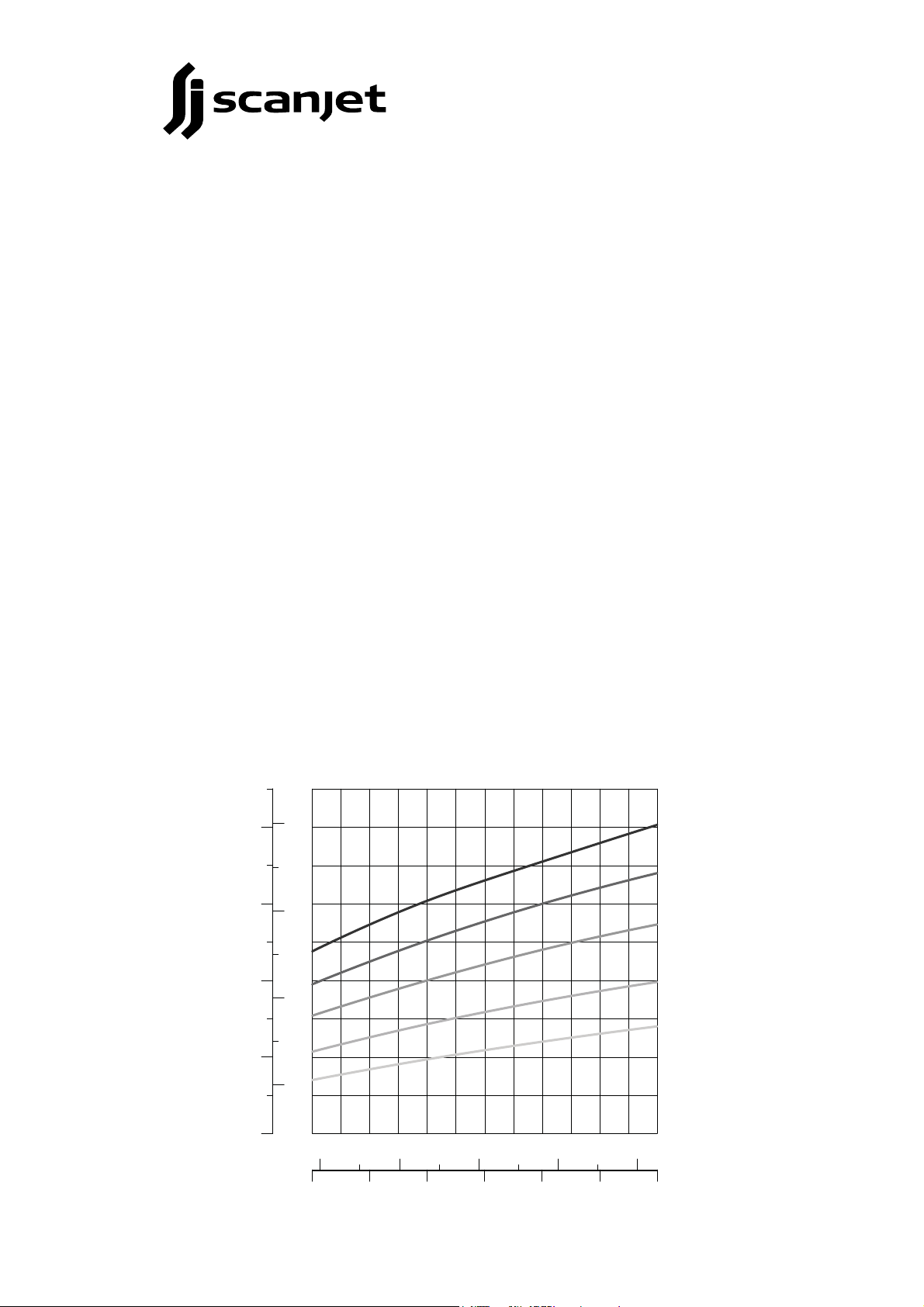

5. Performance Data......................................................................................... 9

6. Installation Instructions............................................................................... 12

6.1. Connecting to Supply Line ............................................................................13

7. Maintenance............................................................................................... 14

7.1. Preventive maintenance ................................................................................14

7.2. Service kits....................................................................................................15

7.3. Service intervals ............................................................................................16

7.4. Disassembly ..................................................................................................17

7.5. Reassembly ...................................................................................................21

8. Trouble Shooting Guide.............................................................................. 24

9. How to Order Spare Parts........................................................................... 25

10. Exploded Drawing View ........................................................................... 26

11. Spare Parts List - BIO 25......................................................................................27

12. Spare Parts List - Old Versions ............................................................................29

13. Accessories ............................................................................................... 30

13.1. Welding Adapter.........................................................................................30

14. Service Kit Contents ................................................................................. 32

15. Basic Settings............................................................................................ 33

15.1. BIO 25 - 4 nozzles .......................................................................................33

16. Tool Kit ..................................................................................................... 34

16.1. Standard Tool..............................................................................................34

16.2. Optional Tool..............................................................................................34

17. Service Card.............................................................................................. 35

18. Claim Report ............................................................................................ 37