Introducing the SK22368GTOC-LA Line Scan Camera

Instruction Manual SK22368GTOC-LA shared_Introduction_GigE_ML.indd

4

Instruction Manual SK22368GTOC-LA © 2018-11 E

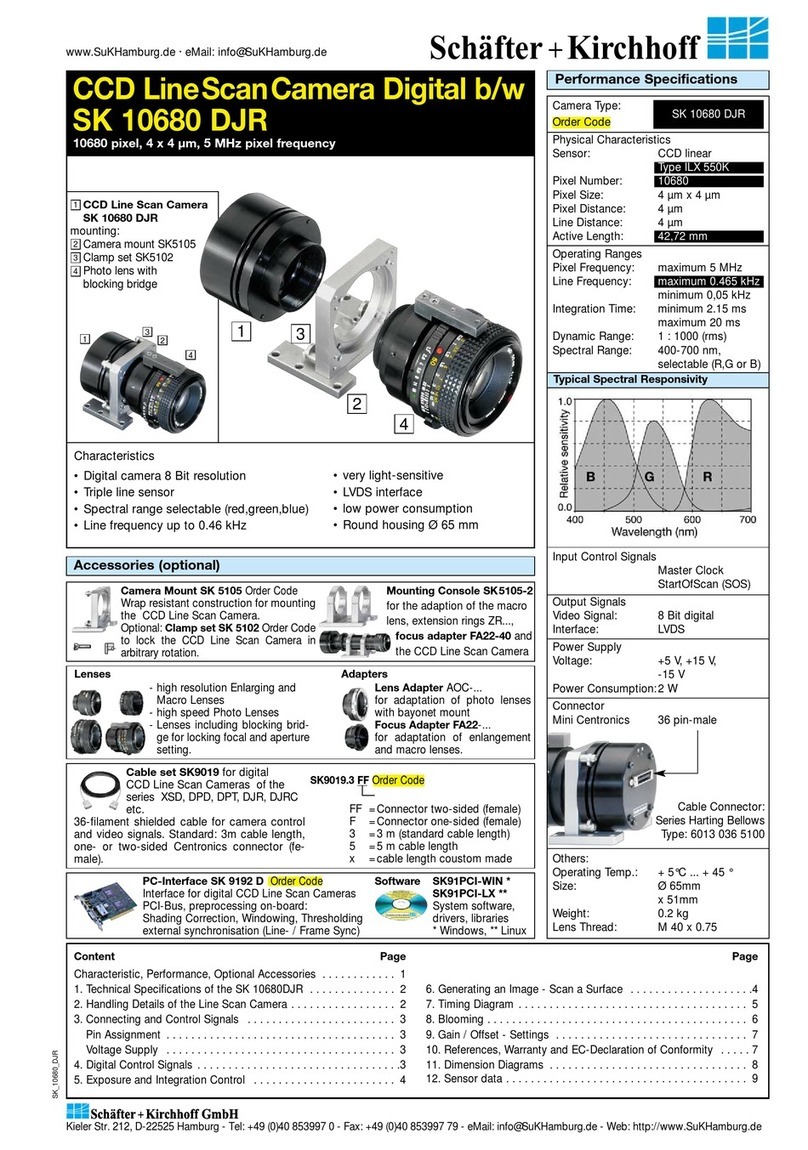

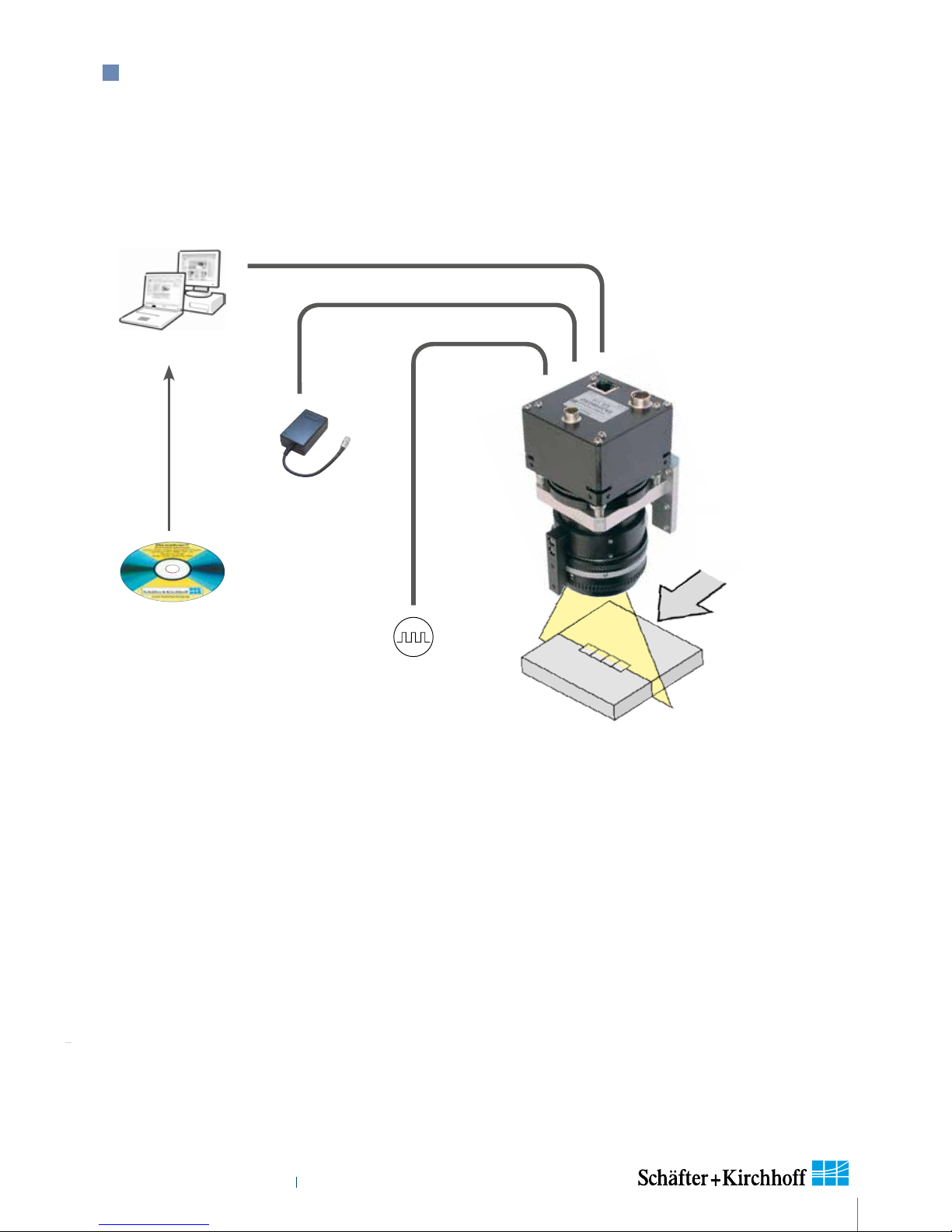

The SK line scan camera series is designed for a wide

range of vision and inspection applications in both

industrial and scientific environments. The GigE series

camera SK22368GTOC-LA uses the Gigabit Ethernet

communication protocol, enabling fast image transfer

using low cost standard cables up to 100 m in length. The

Gigabit Ethernet interface makes the line scan camera

highly scalable to faster Ethernet speeds, distinguishing

it with high performance and total flexibility.

All of the GigE cameras from Schäfter+Kirchhoff are

externally synchronizable and no grabber board is

needed as signal preprocessing is performed inside the

camera and does not impinge on CPU use.

Additional features include:

• customer-specific I/O signals in addition to the video

signal

• specialpreprocessingalgorithmscanbeimplemented

in the camera

• consistent attribution of camera IDs in multi-camera

operations

• SDK from Schäfter+Kirchhoff with the SkLineScan

operating program, libraries and examples.

1 Introducing the SK22368GTOC-LA Line Scan Camera

1.1 Intended Purpose and Overview

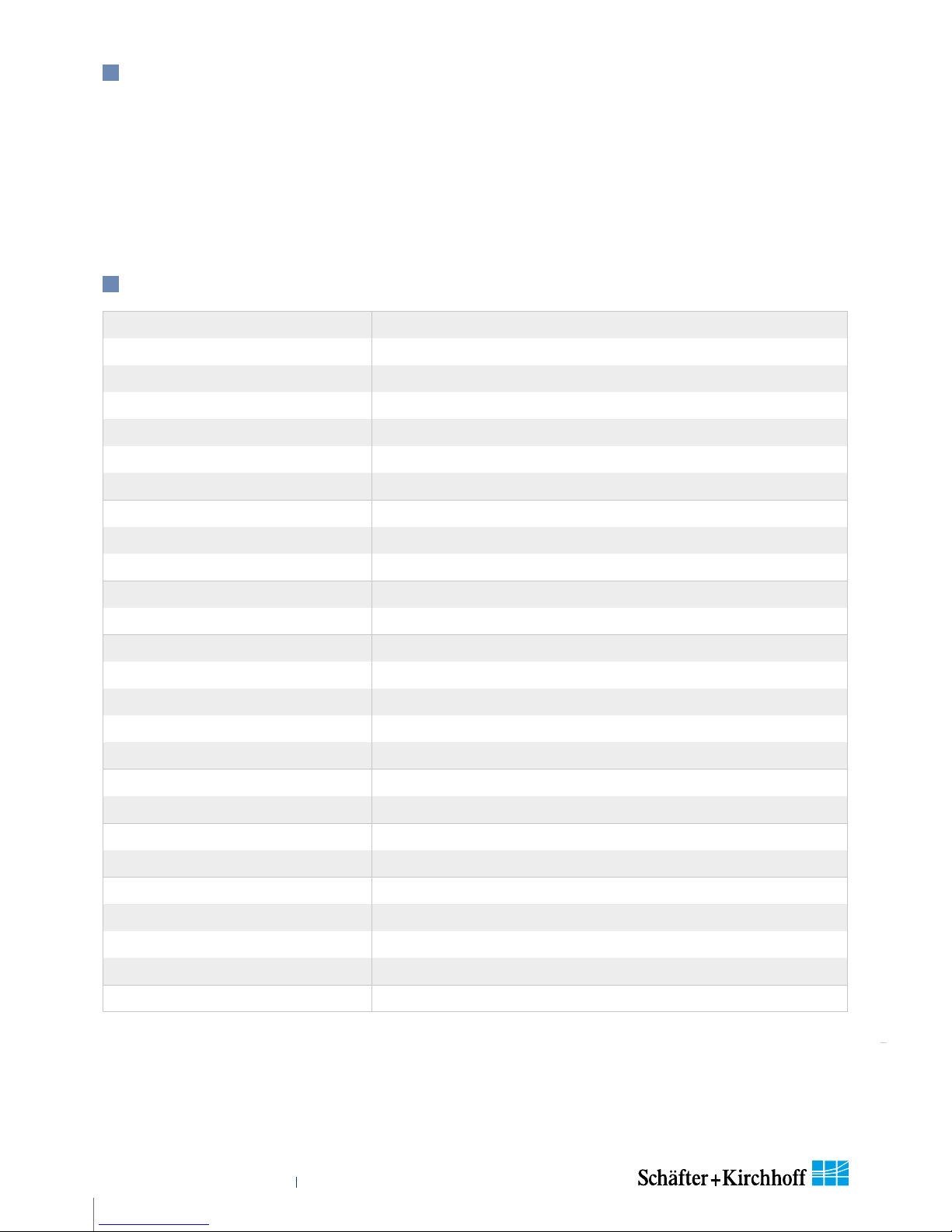

Features

Shading Correction X

Programmable Lookup Table X

Thresholding X

Window Function (ROI) X

Line Trigger, Frame Trigger X

Frame Trigger Delay X

Threshold Trigger X

Advanced Synchonization Ctrl. X

Integration Control for R, G, B X

Decoupling of line frequency X

Extra signals for diagnosis X

Data cable length 100 m

Windows SK91GigE-WIN SDK

LabVIEW SK91GigE-LV VI Library

Linux -

The camera can be connected to a computer either via

the GigE socket directly or through a Gigabit Ethernet

switch.

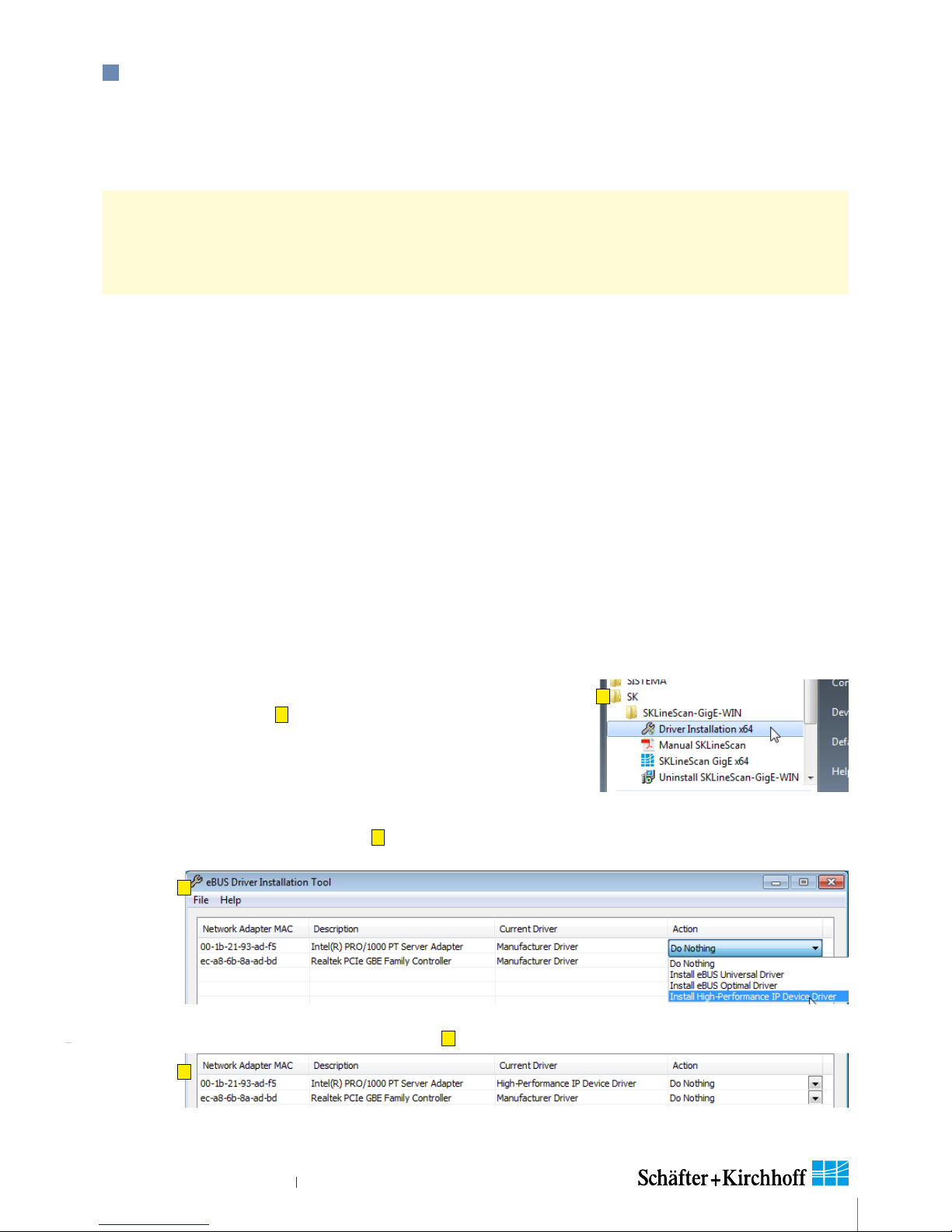

Once the camera driver and the SkLineScan® program

have been loaded from the SK91GigE-WIN CD then the

camera can be parameterized. The parameters, such

as integration time, synchronization mode or shading

correction, are permanently stored in the camera even

after a power-down or disconnection from the PC.

The oscilloscope display in the SkLineScan® program

can be used to adjust the focus and aperture settings, for

evaluating field-flattening of the lens and for orientation

of the illumination and the sensor, see 3 Camera Control

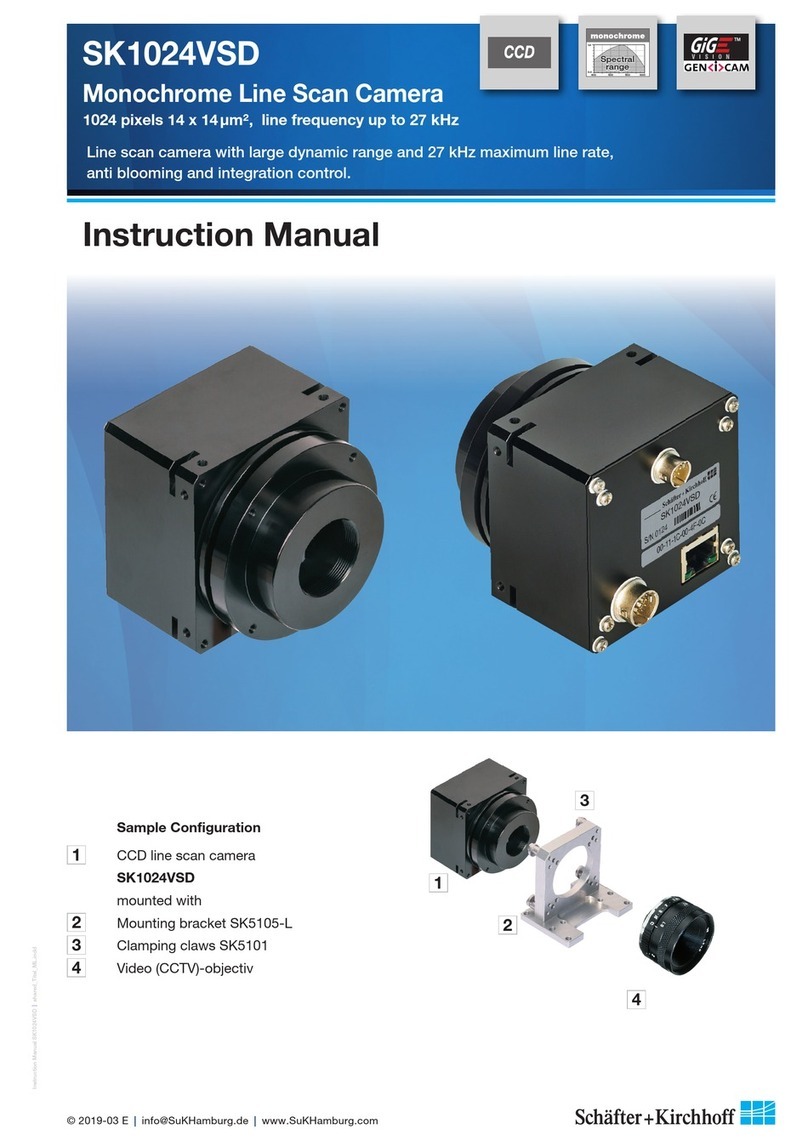

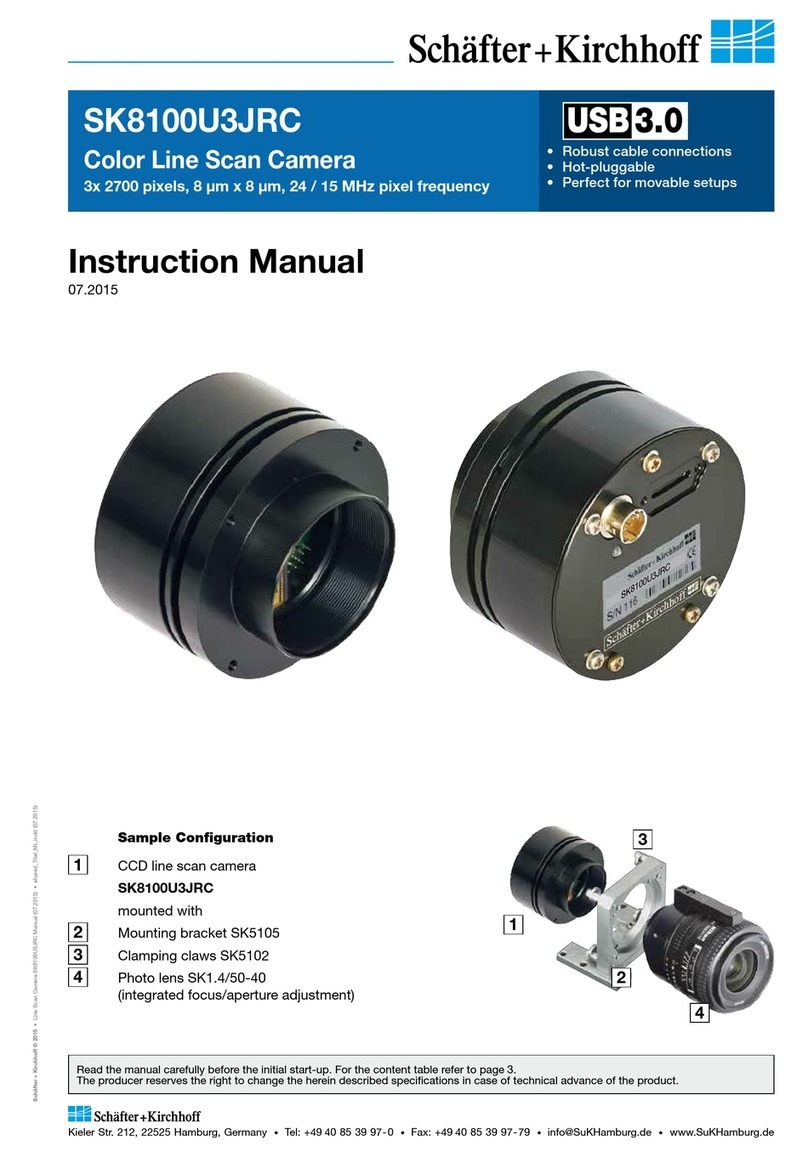

and Performing a Scan (p. 12).CCD line scan camera

2Power supply

3Illumination

Software, SDKs and eBus

driver

GigE switch

14

5

PC or

Notebook

with GigE

GigE interface for transmission

of video and control data over

distances up to 100 m

421

3

Advanced

preprocessing

Fixed camera

IDs for multi-

camera systems

Application:

Parallel

acquisition

using a

GigE switch

4

2

1

5