Introducing the SK512CSH Line Scan Camera

Instruction Manual SK512CSH shared_Introduction_CamLink.indd

4

Instruction Manual SK512CSH © 2020-11 E

1 Introducing the SK512CSH Line Scan Camera

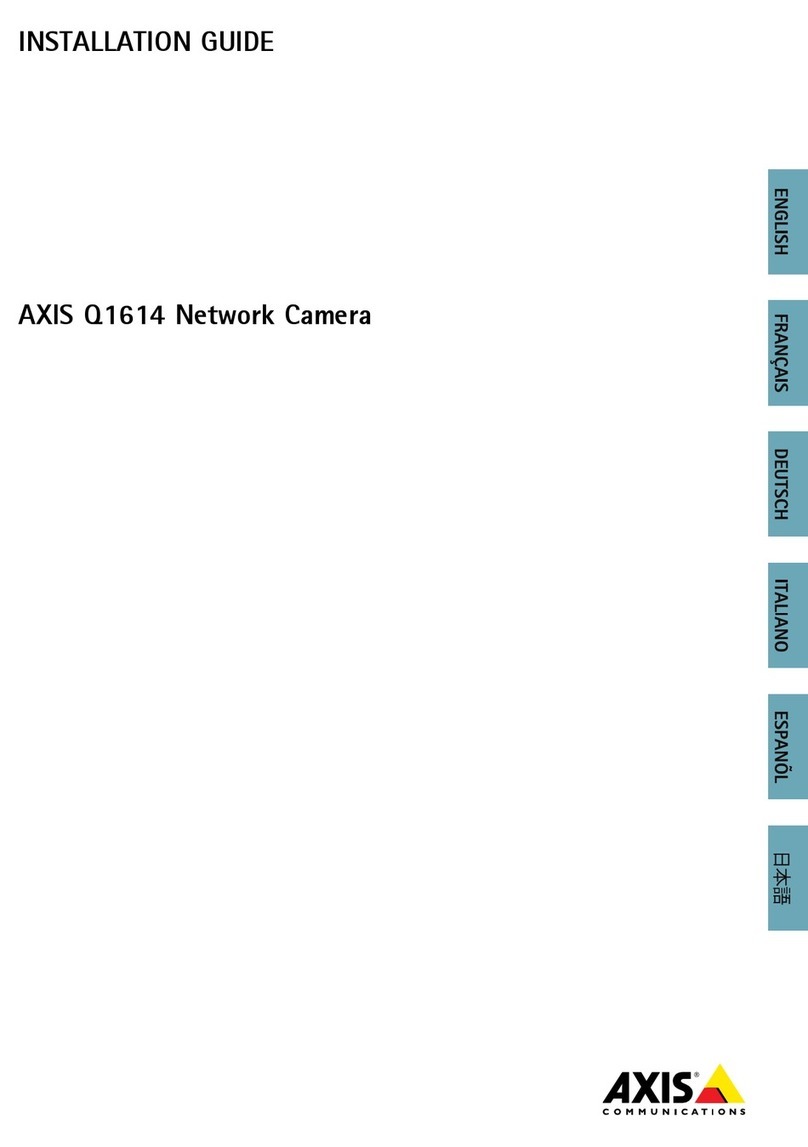

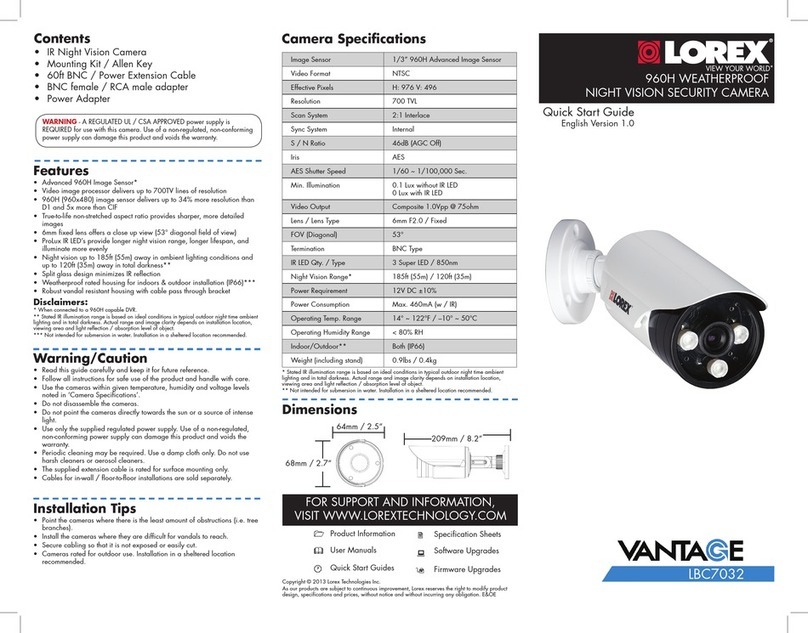

PC

CameraLink

grabber for PC

12

3

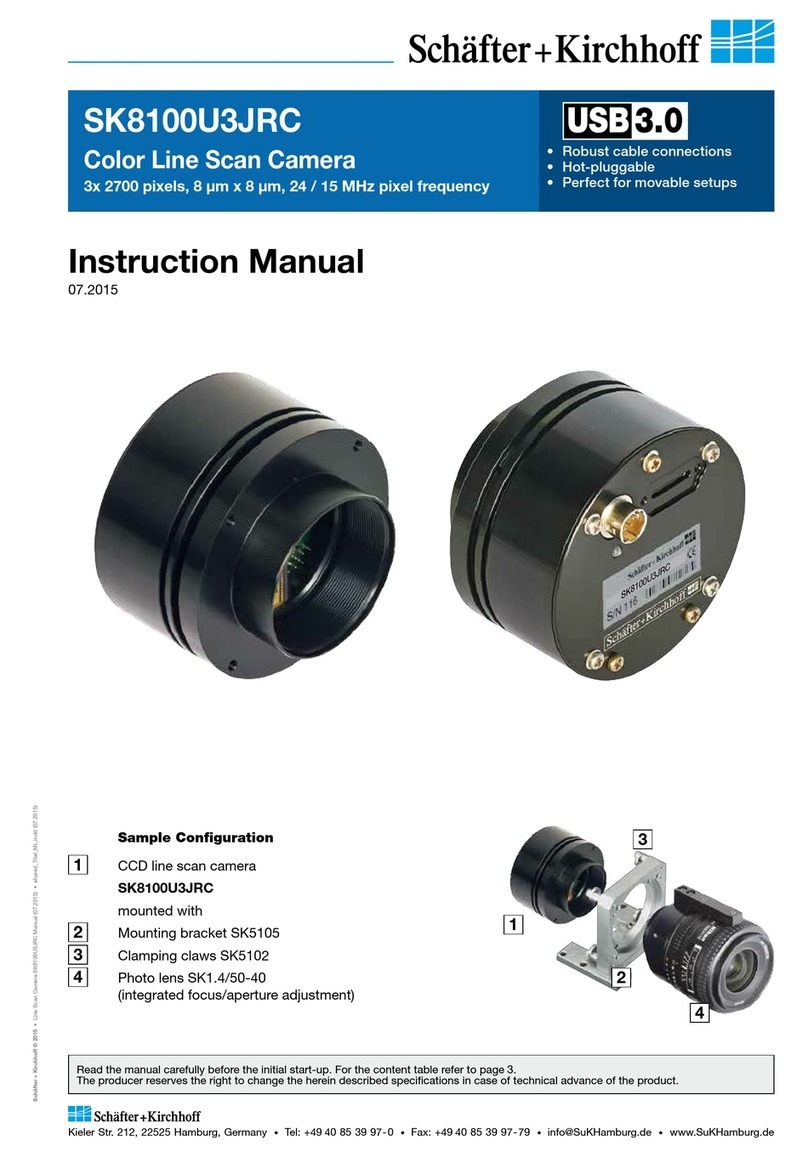

1Line Scan Camera

2Power Supply

3Illumination

4Grabber with base

configuration

4

Normally, functions like Shading Correction, signal

modification with a look-up table (LUT) or the definition

of a region of interest (ROI) are implemented in

the grabber board. For special requirements these

functions can be made availabel within the camera,

please contact the Schäfter +Kirchhoff customer

support where appropriate.

The camera is supplied precalibrated, with factory

settings for gain and offset. A readjustment is normally

not necessary.

The successful use of the line scan camera requires

that the complete optical system is properly set up,

especially the location of the illumination, the degree

of focus of the lens and the aperture setting. The most

critical factor is the perpendicular alignment of the

sensor axis either with the object to be measured or the

direction of its relative travel when scanned. For further

guidance see section 4.2 Adjustments for Optimum

Scan Results (p. 15).

The SK line scan camera series is designed for a wide

range of vision and inspection applications in both

industrial and scientific environments. The SK512CSH

is compliant with CameraLink Specification Rev 1.1.

Data acquisition requires that the grabber board

conforms to the CameraLinkTM standard. The grabber

board provides the Start-Of-Scan (SOS) signals

and thereby determines the exposure time and line

frequency of the camera.

CameraLink reads the camera specifications from

configuration files. Prior to the iniatial start-up, the

appropriate camera specific file must be created for the

grabber in use.

Beyond, the configuration program SkCLConfig allows

the full parameterization of the camera settings, such

as gain, offset and pixel frequency, via the Camera-

LinkTM serial port interface. SkCLConfig uses the clser*.

dll driver that is supplied with the CameraLink grabber

board.

For the development of custom applications use the

software development kits released from the grabber

board producers.

1.1 Intended Purpose and Overview