Line Scan Camera SK22368U3TOC-LA Manual (12.2016) • shared_Installation-Software_USB3.indd (12.2016)

8SK22368U3TOC-LA Instruction Manual (12.2016) © 2016

Schäfter + Kirchhoff GmbH • Hamburg

Installation and Setup

2.3 USB3 Connections and SkLineScan Software Installation

Installation and Setup

This section is a quick reference for installing the SkLineScan adjustment and configuration software and to set

up the USB3 camera driver. SkLineScan and the SkLineScan manual is provided for download on the

Schäfter + Kirchhoff website under http://www.sukhamburg.com/support.html. It is also part of the fee-based

software development kit SK91USB3-WIN.

SkLineScan Installation and Automatic Camera Driver Installation

Prior to the installation, power on the PC (not the camera) and unpack the downloaded zip-file to a temporary

folder. Alternatively, if your installation medium is a CD, insert the disk to the drive.

The autostart function may launch the setup program automatically from CD. Otherwise, look for one of these

installation files:

SkLineScan-USB3-Win_x64.msi SK91USB3-Win_x64.msi

SkLineScan-USB3-Win_x86.msi SK91USB3-Win_x86.msi

Then start the applicable installation file manually. This will set up the Schäfter + Kirchhoff SkLineScan camera

control and adjustment tool as well as the USB3 Line Scan Camera Driver.

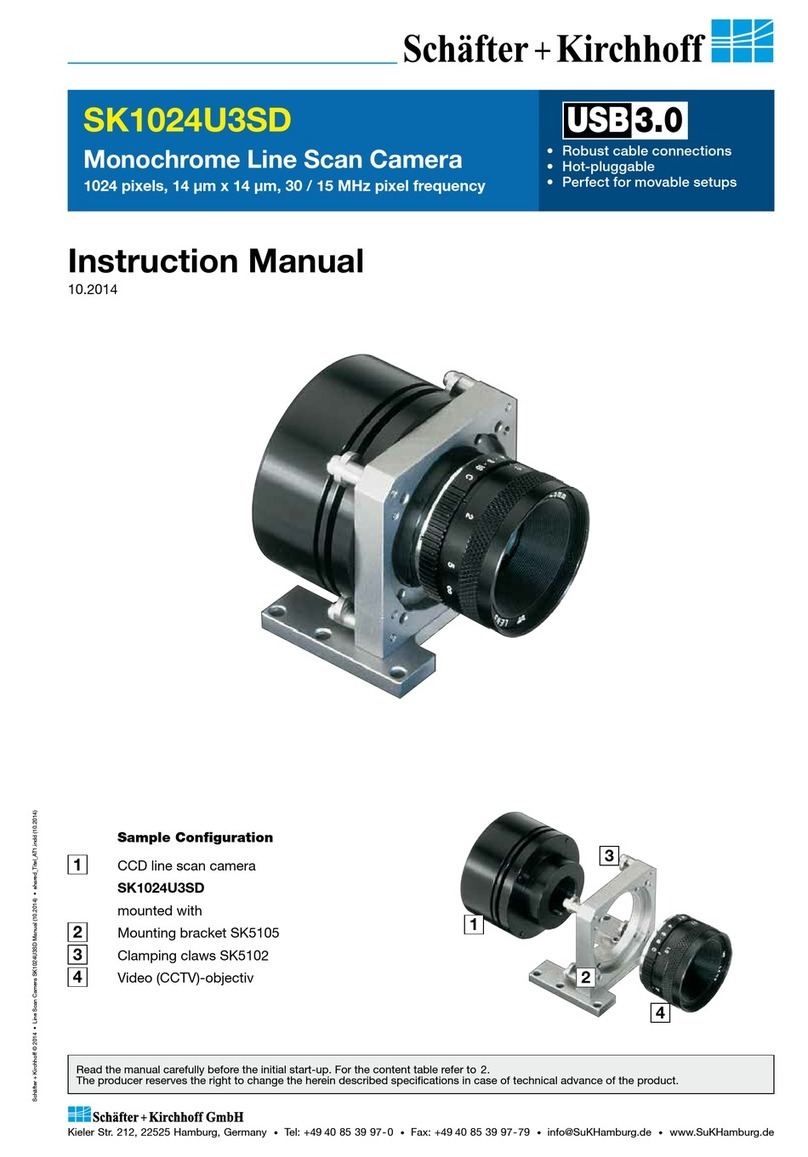

Step 1: Install SkLineScan. The setup program will

automatically install the Schaefter +

Kirchhoff USB3 Line Scan Camera Driver.

Step 2: Plug in the USB3 connection cable to the

camera. if appropriate switch on the external

power supply.

Step 3: Start the SkLineScan program.

Initial Function Test

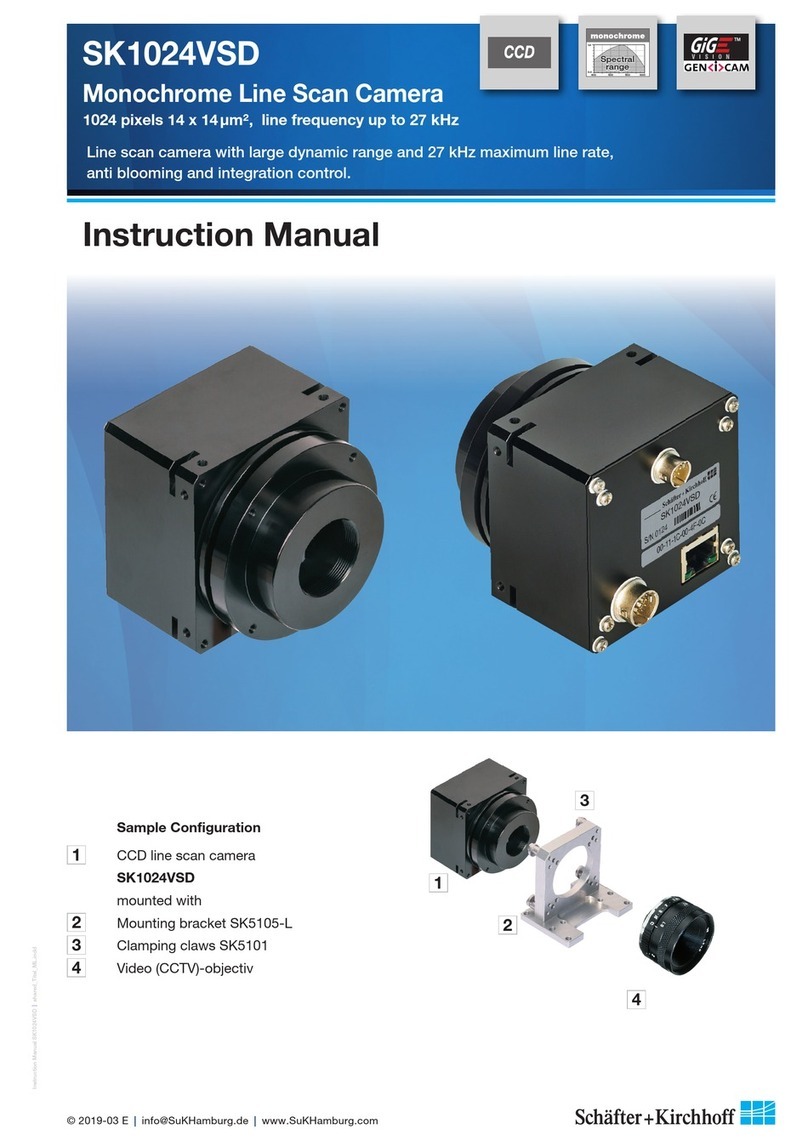

• Quit the SkLineScan startup dialog

box.

• Select "OK" in the SkLineScan

start-up dialog.

The Signal Window showing the current

brightness versus the pixel number

indicates the correct installation.

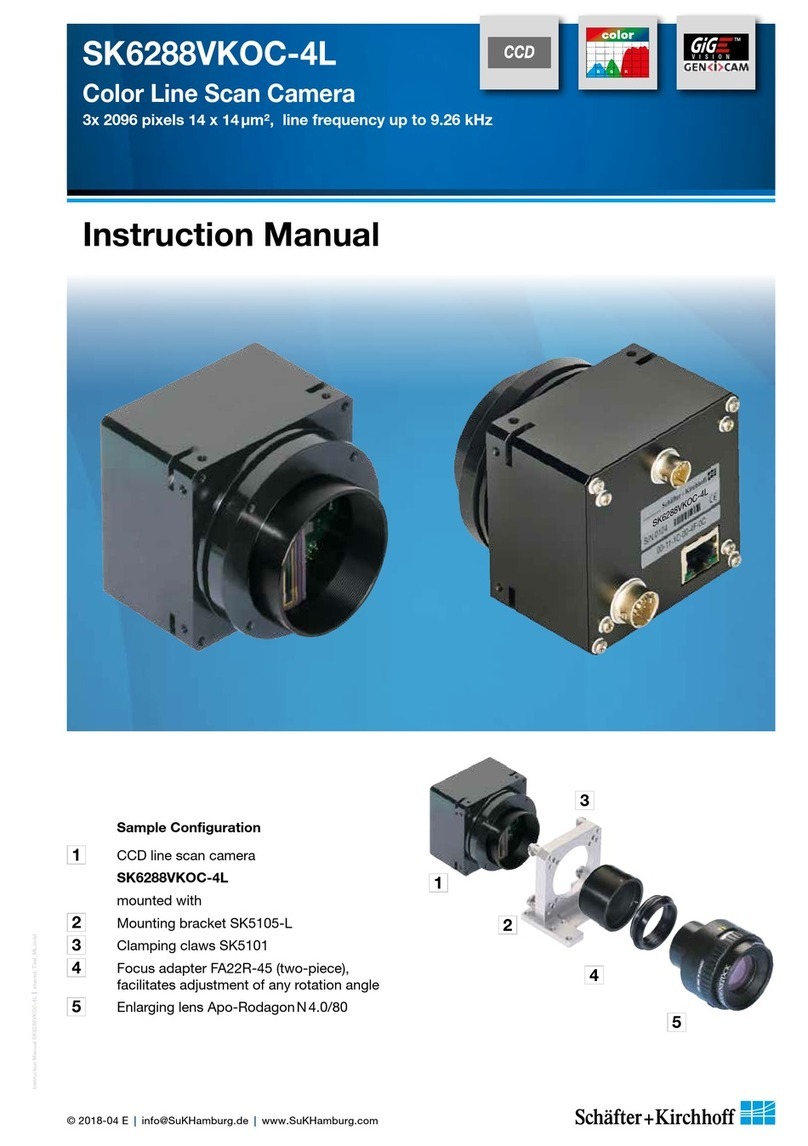

Camera Setup

Use the Setup dialog for

• activating/deactivating a connected USB3 camera

(activated device is ticked)

• changing the pixel frequency

• setting the bit depth of the video signal to 8 or 12-bit.

In USB 2.0 mode the lower pixel frequency and 8-bit video

signal is recommended SkLineScan Setup dialog

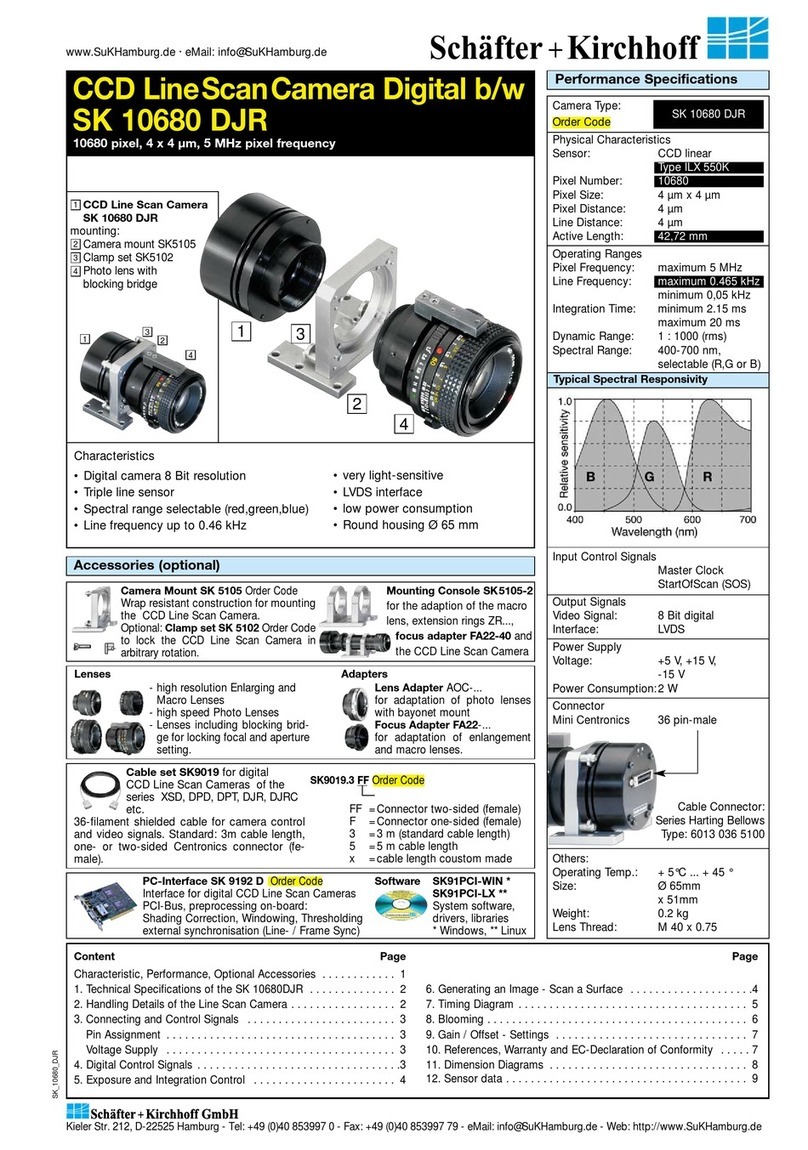

SkLineScan Start-up

• Start SkLineScan.

• A start-up dialog box pops up and

displays the connected camera(s) that

have been automatically detected. It

also indicates the active USB standard. The optimum

performance is provided by USB3.0.

• The camera LED changes from red to green color light.

Desktop Icon