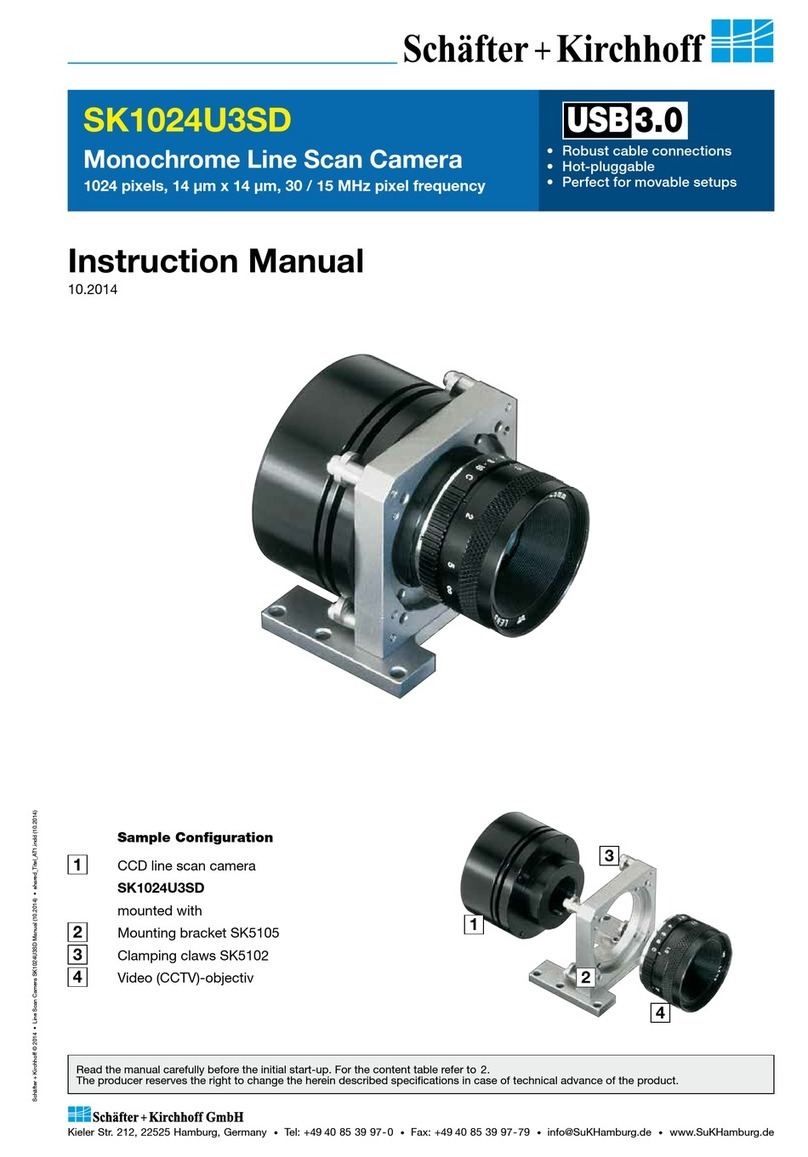

Introducing the SK1024VSD Line Scan Camera

Instruction Manual SK1024VSD shared_Introduction_GigEV_ML.indd

4

Instruction Manual SK1024VSD © 2019-02 E

The SK line scan camera series is designed for a wide

range of vision and inspection applications in both

industrial and scientific environments.

The SK1024VSD GigE VisionTM line scan camera uses

the Gigabit Ethernet communication protocol and is

100% compliant with the GigE VisionTM specifications

and the Gen<I>CamTM standard.

GigE Vision allows for fast image transfer using low

cost standard cables up to distances of 100m. With

GigE Vision, hardware and software from different

vendors can interoperate seamlessly via the GigE

connections. The camera is connected to a computer

either via the GigE socket directly or through a Gigabit

Ethernet switch.

When taking the camera into operation the first time

the Schäfter+Kirchhoff SkLineScan®program is recom-

mended. Once the camera driver and the SkLineScan®

program have been loaded from the SkLineScan CD

or zip-file then the camera can be parameterized. The

parameters, such as integration time, synchronization

mode or shading correction, are permanently stored in

the camera even after a power-down or disconnection

from the PC.

The oscilloscope display in the SkLineScan®program

can be used to adjust the focus and aperture settings,

for evaluating field-flattening of the lens and for orien-

tation of the illumination and the sensor, see 14.6 GigE

Connections and SkLineScan Software Installation (p.

69).

The Schäfter + Kirchhoff GigE Vision line scan

cameras implement a superset of the Gen<I>Cam™

specification which defines the device capabilities.

The settings made in the SkLineScan®program are

automatically provided to the device feature liste of any

Gen<I>Cam compliant software.

The Gen<I>CamTM standard provides a generic

programming interface for all kinds of cameras and, no

matter what features they implement, the application

programming interface (API) always remains the same.

The Gen<I>CamTM standard consists of multiple

modules relevant to the main tasks to be solved:

GenApi: for configuring the camera

Standard Feature Naming Convention (SFNC): recom-

mended names and types for common features

GenTL: transport layer interface, for grabbing images

For more information on the GigE VisionTM specifi-

cation, see:

https://www.visiononline.org/vision-standards-details.

cfm?type=5

or the Gen<I>CamTM standard:

http://www.emva.org/standards-technology/genicam/

1 Introducing the SK1024VSD Line Scan Camera

1.1 Intended Purpose and Overview

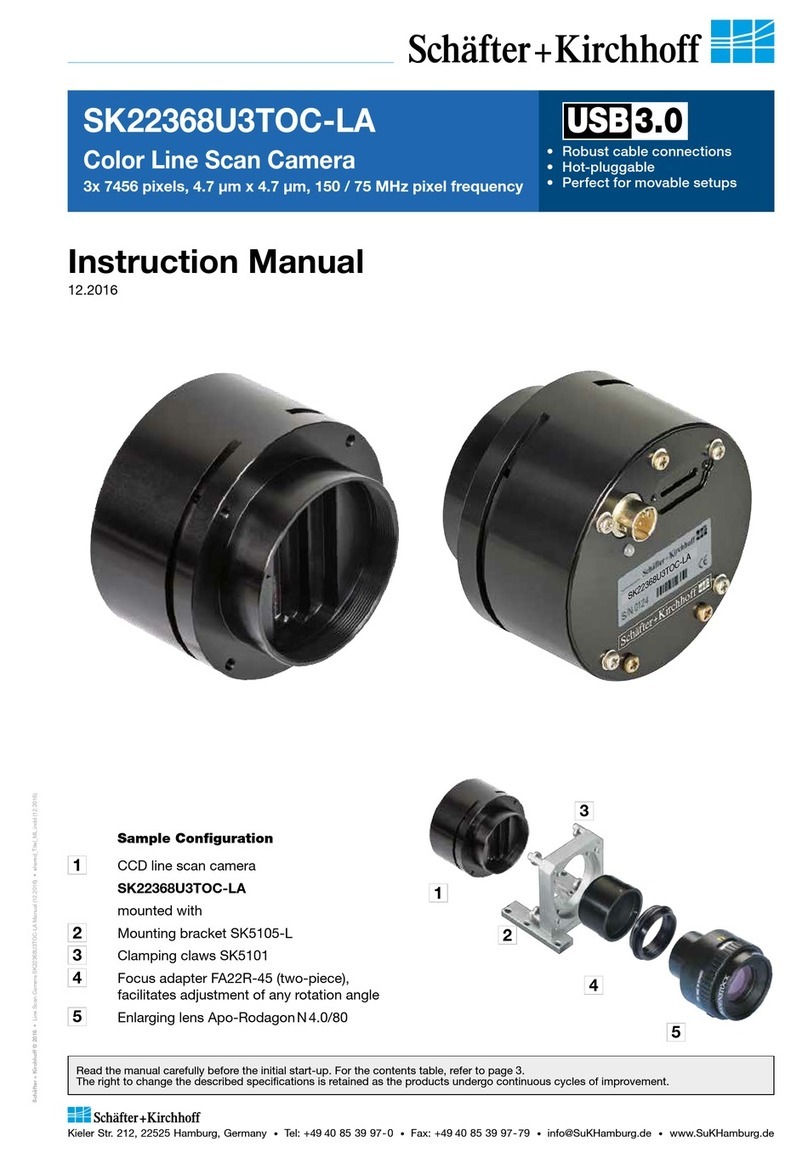

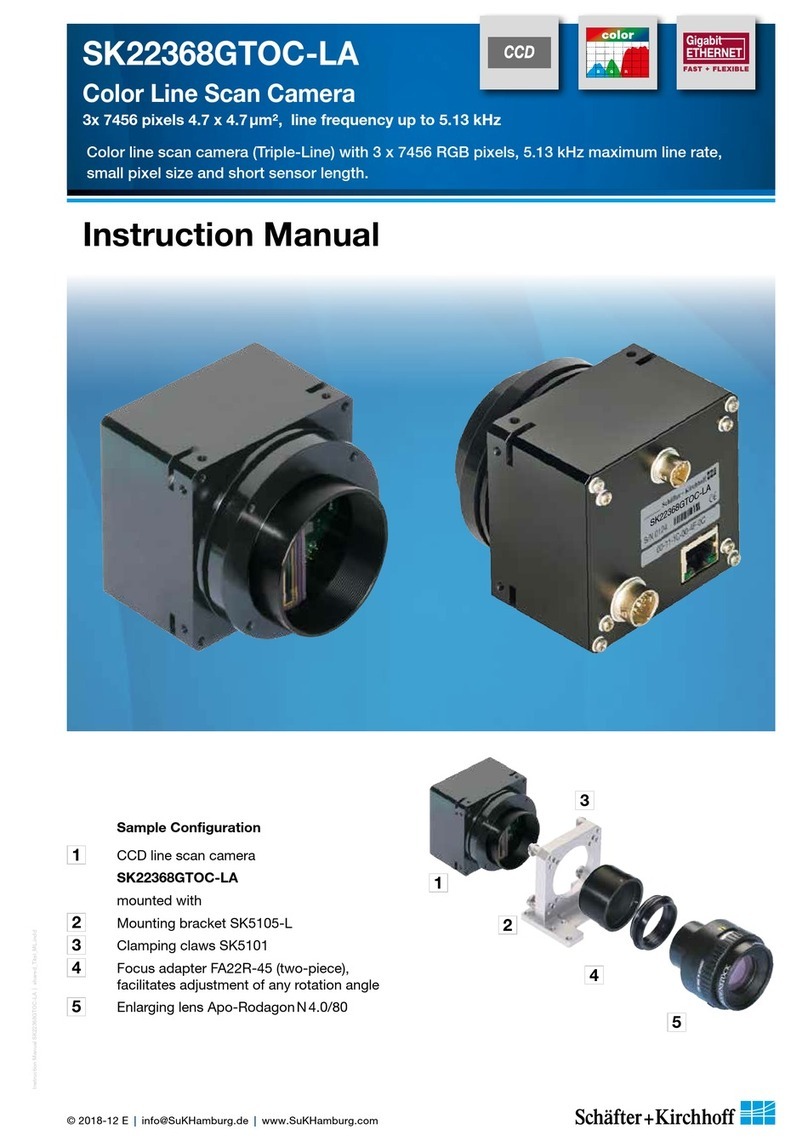

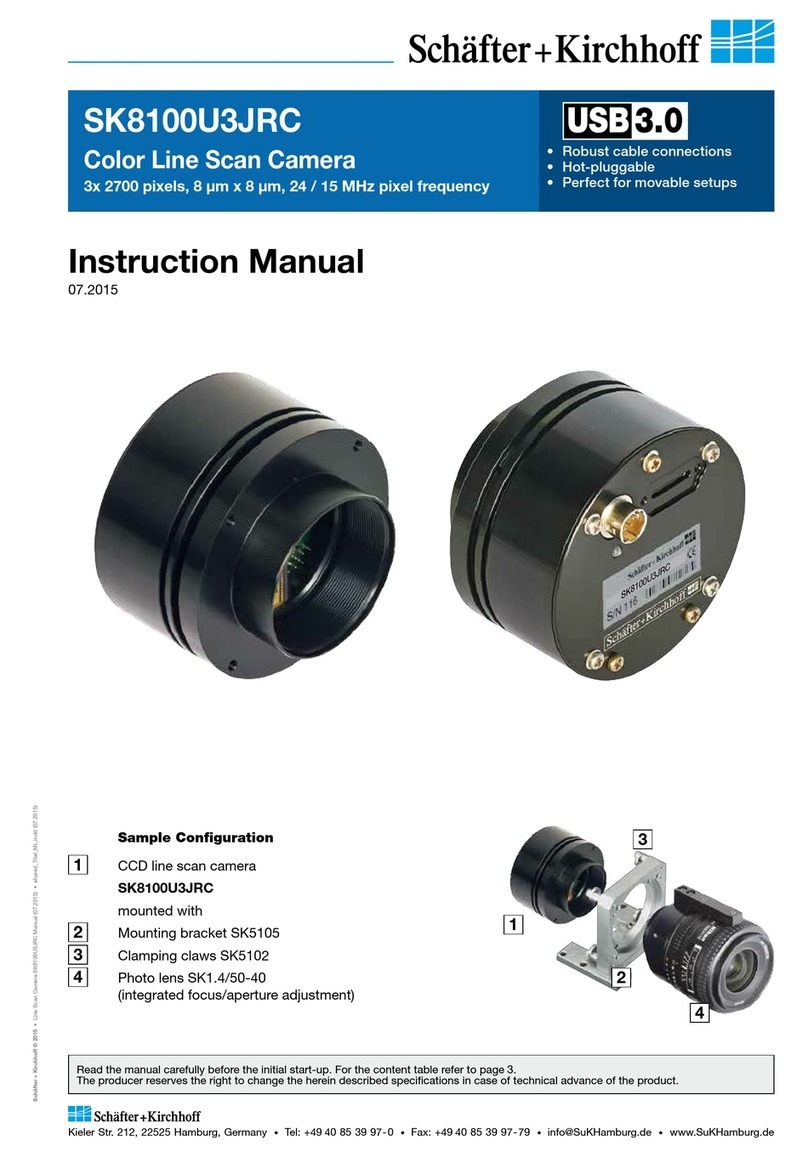

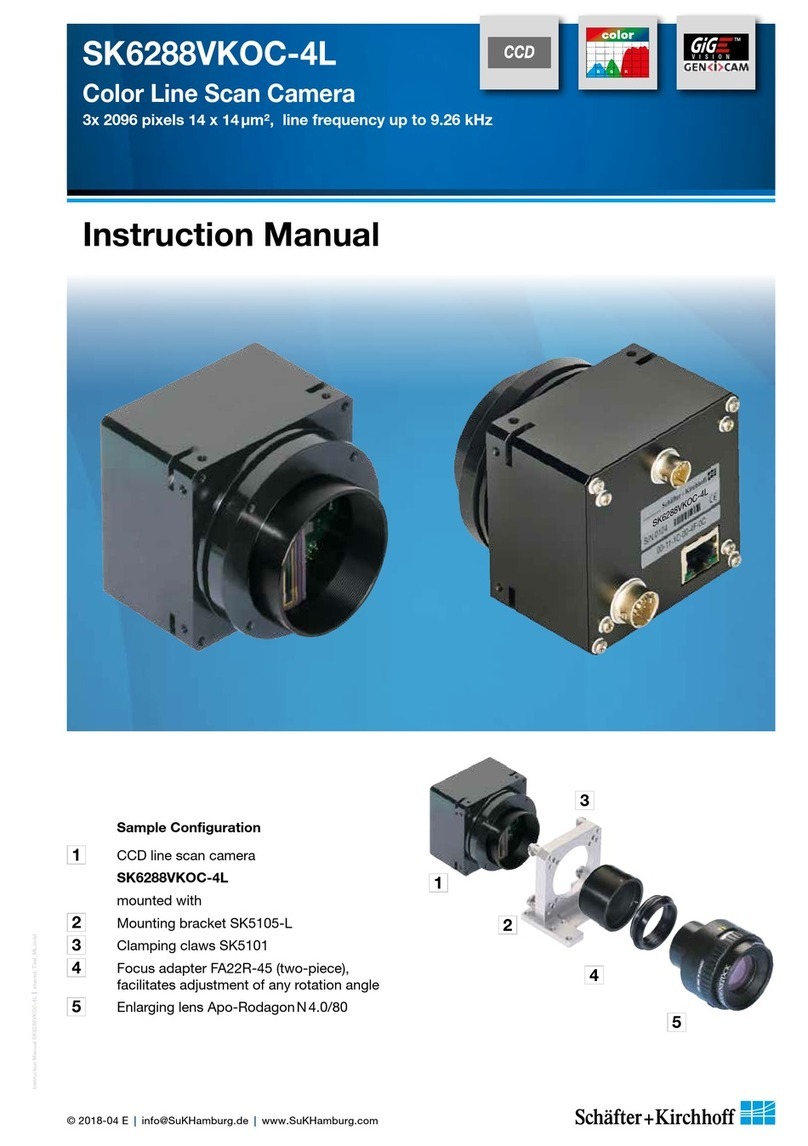

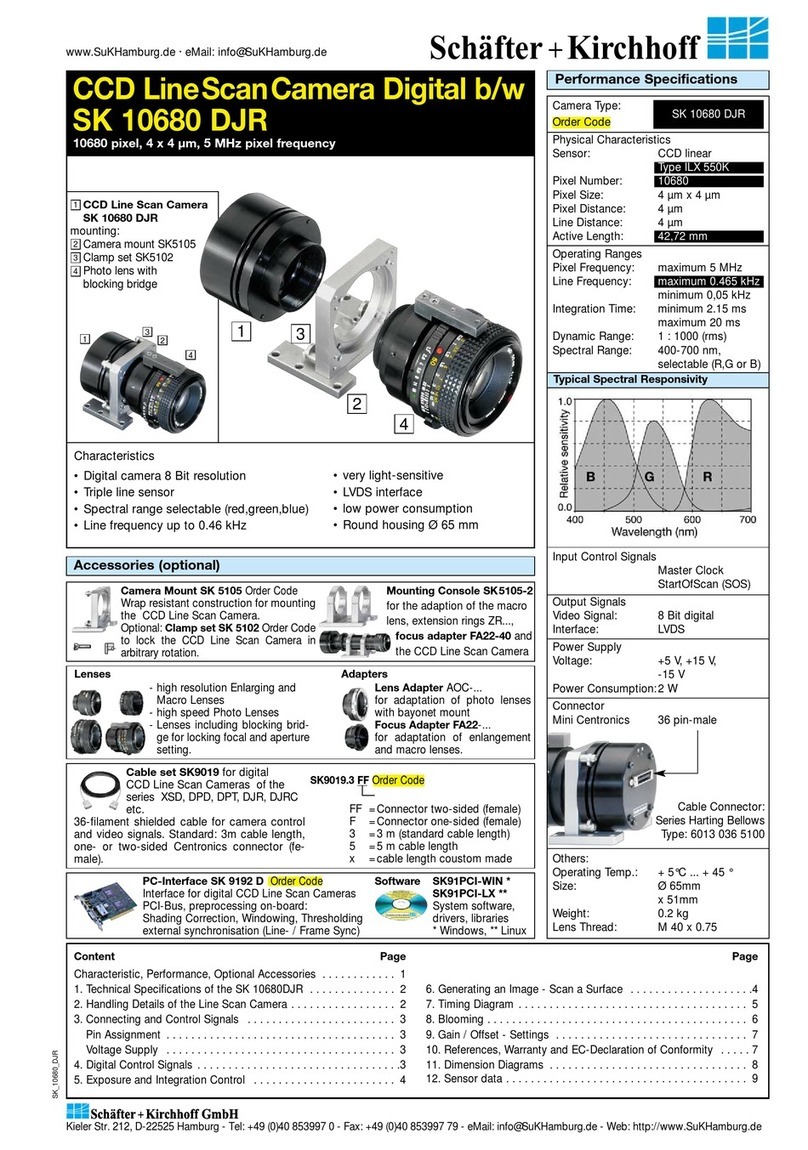

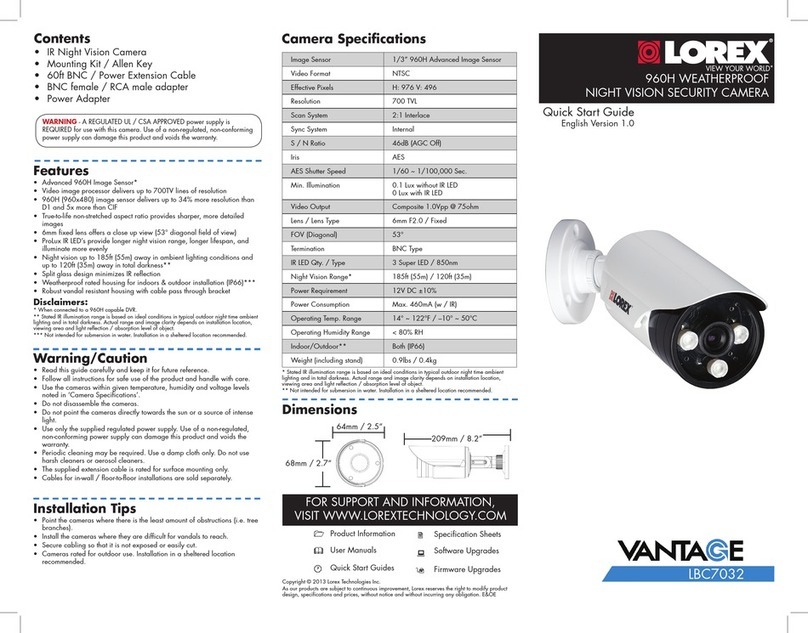

CCD line scan camera

2Power supply

3Illumination

Software Gen<i>Cam

-compliant, eBus driver

GigE switch

14

5

PC or

Notebook

with GigE

GigE interface for transmission

of video and control data over

distances up to 100 m

421

3

Application:

Parallel

acquisition

using a

GigE switch

4

2

1

5