Line Scan Camera SK8100U3JRC Manual (07.2015) • shared_Installation-Software_USB3.indd (07.2015)

8

2 Installation and Setup

SK8100U3JRC Instruction Manual (07.2015) © 2015

Schäfter + Kirchhoff GmbH • Hamburg

2.3 Software Installation

SK91USB3-WIN Installation

1. Power on the PC and insert the SK91USB3-WIN

CD to the disk drive.

2. The autostart function will launch the setup

program automatically. If it is deactivated, start the

setup.exe in the root folder of the CD manually.

3. Follow the display instructions and finish the

installation of the software package

SK91USB3-WIN.

Driver Installation

1. Connect the camera to a USB 3.0 connector of the

PC. The camera status indicator (LED) will indicate

the correct power supply for the camera with a red

light. No red light means there is a USB interface

failure, e.g. a faulty connector or cable.

2. The Windows operating system will detect a new

USB device and the Hardware Assistant will guide

you through the installation process.

3. Advise the Hardware Assistant to look for the best

driver on the local PC.

4. Navigate to the folder \Program Files (x86)\SK\

SK91USB3-WIN\Driver.

5. For a 64 bit operating system click on the subfolder

"x64", for a 32 bit system click on "x86".

6. Carry on with automatic driver installation. Ignore

missing driver signature.

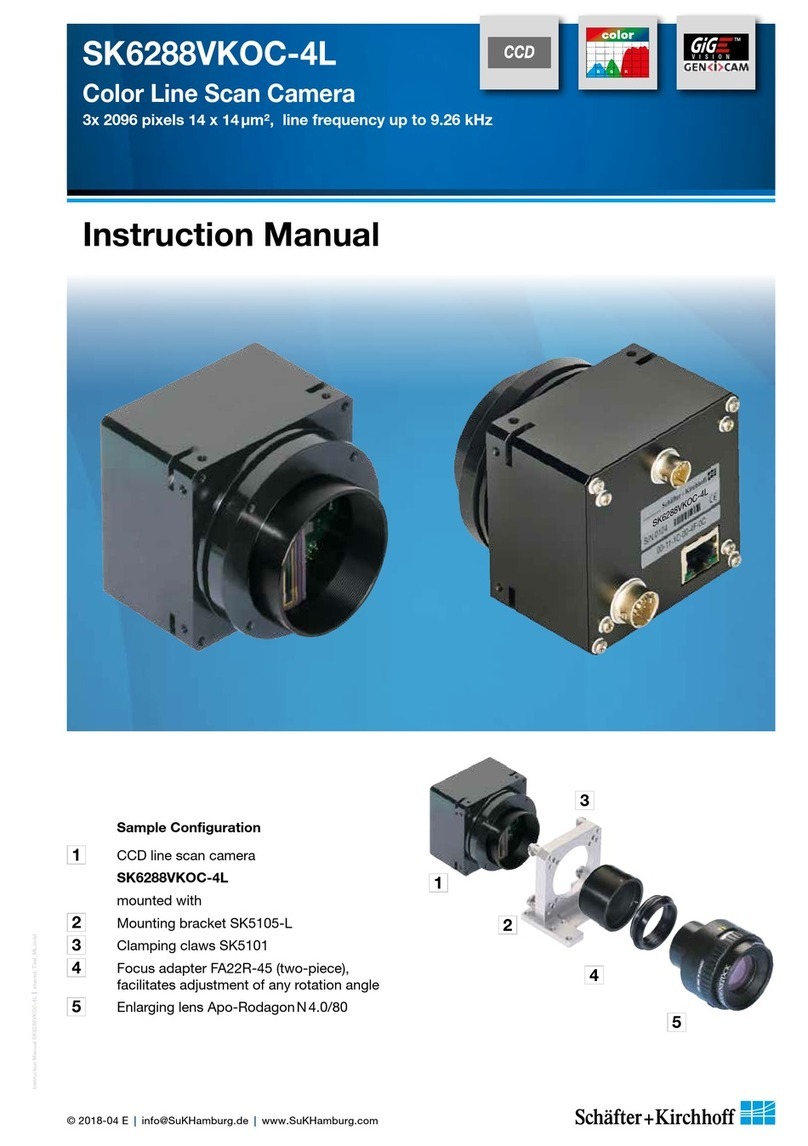

SkLineScan Start-up

• Start SkLineScan. A start-up dialog box pops up and

displays the connected cameras that have been

automatically detected.

SkLineScan start-up dialog

• Ensure the displayed camera type is identical with

the connected line scan camera. If necessary shut

down the program, disconnect the camera and wait

a few seconds. Then reconnect the camera and start

SkLineScan once again.

• The start-up dialog also indicates the active USB

standard. The optimum performance is provided by

USB 3.0.

• The camera LED should now light up green.

Initial Function Test

• Quit the SkLineScan startup dialog box.

• Select "OK" in the SkLineScan start-up dialog.

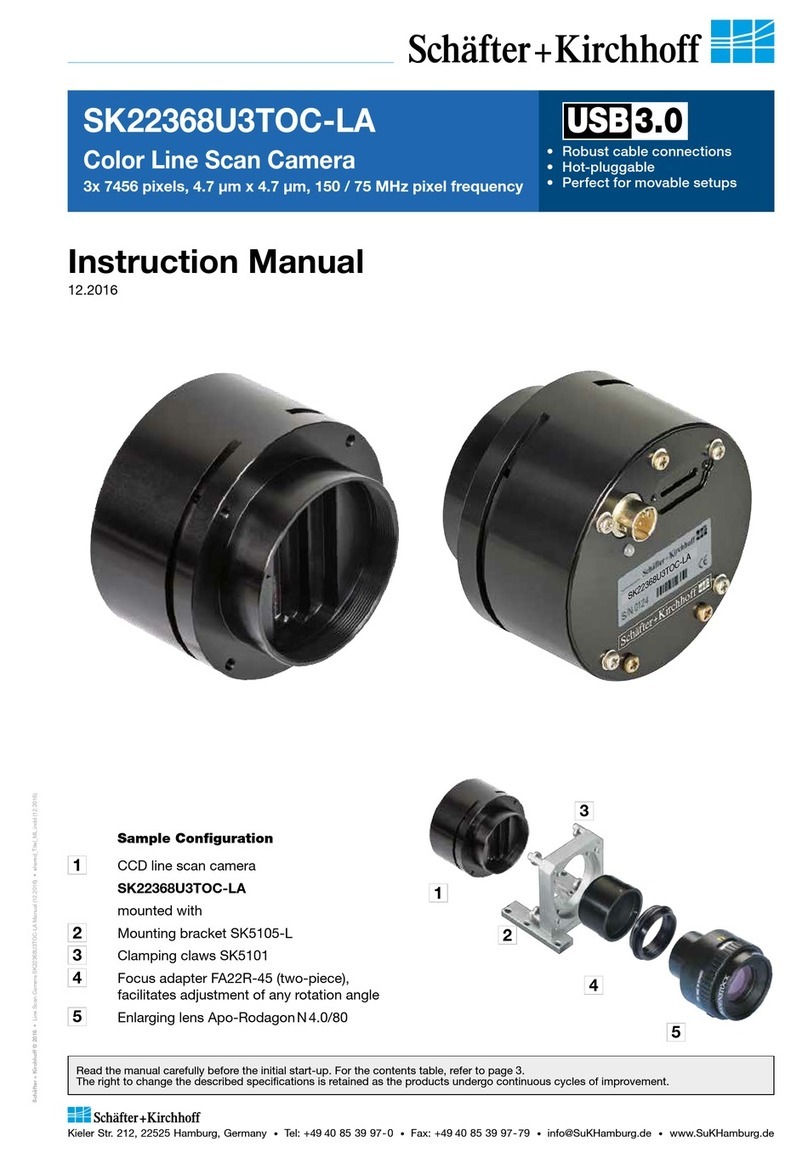

The oscilloscope display showing the current brightness

versus the pixel number indicates the correct

installation.

Line scan in oscilloscope display (brightness vs.

pixel number)

(Basic Visualization of the Sensor Output, p. 11)

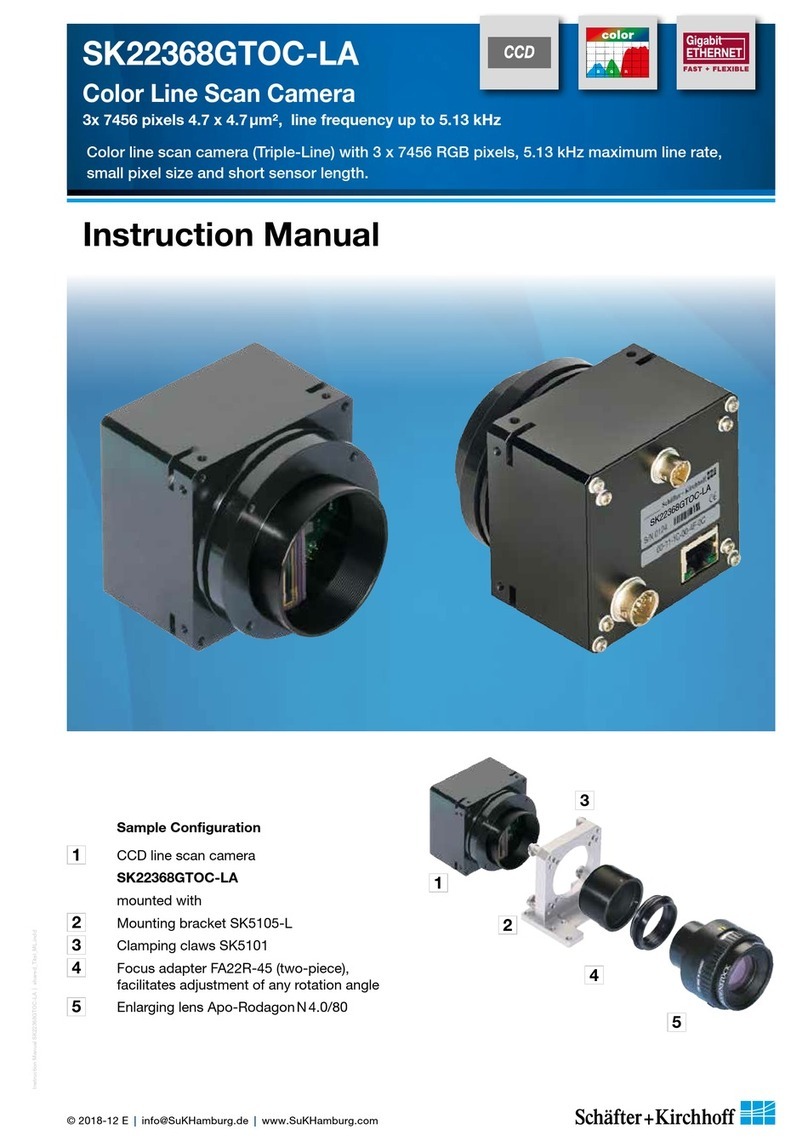

Camera Setup

SkLineScan setup dialog

For changing bit depth or pixel frequency the Setup

dialog must be started from the star-up dialog by pressing

the Setup button.

The default setting for the pixel frequency is the maximum

value. The lower value is perferable e.g. when in USB 2.0

mode. In case of USB 2.0 mode 8 bit bit depth is recom-

mended. The USB 2.0 mode can be caused by connecting

the camera in a USB 2.0 connector or from an unsuitable

cable.

• The PC hardware requirements are listed in section 1.3 Computer System Requirements, p. 5

• See section 2.2 Electrical Installation: Connections and I/O Signals, p. 7. prior to software installation.

• This section focusses on driver installation and initial operation of the camera. For a comprehensive description

of the software package, see the separate SK91USB3-WIN software manual.

2 Installation and Setup