1

3

2

Installation and Setup

7

Instruction Manual SK12240U3KOC-LB shared_Installation-Electric_USB3_ML.indd

Instruction Manual SK12240U3KOC-LB © 2020-03 E

2.2 Electrical Installation: Connections and I/O Signals

All Schäfter+Kirchhoff USB3.0 line scan cameras can be operated with a USB 2.0 interface. Note that there might be

limitations in terms of the maximum data transfer rate. The details for your camera can be found in section 1.4 Line

Scan Camera - Specifications (p. 5).

If the power consumption of the camera exceeds 4.5 Watt (USB3.0) or 2.5 Watt (USB 2.0), then connect an external

source to socket 2.

Installation and Setup

Accessories (see also Accessories (p. 36)):

Combined Synchronization and Power Cable SK9016.1.5

Use this cable to feed external synchronization signals and supply voltage into socket 2.

Connectors:

Hirose plug HR10A, female 6pin (camera side)

Lumberg SV60, male 6-pin connector (for supply voltage)

Phoenix 6 pin connector incl. terminal block (for synchronization signals)

Standard length 1.5m

Power Cable SK9015.xMF

Use this cable to feed external supply voltage into socket 2.

Connectors:

Hirose plug HR10A, female 6pin (camera side)

Lumberg SV60, male 6-pin connector (for supply voltage)

Length 1.5 m (standard) or 0.2 m

USB 3.0 cable SK9020.3

For connecting socket 1with the PC or USB hub. Standard length 3.0 m

Power Supply Unit PS051515

Input: 100-240 VAC, 0.8 A, 50/60 Hz IEC 320 C14 coupler

(for IEC C13 power cord)

Output: +5V DC, 2.5 A / +15 V DC, 0.5 A / -15 V DC, 0.3 A

Cable length 1 m, with Lumberg connector KV60, female 6-pin

(for power cable SK9015.x or SK9016.x)

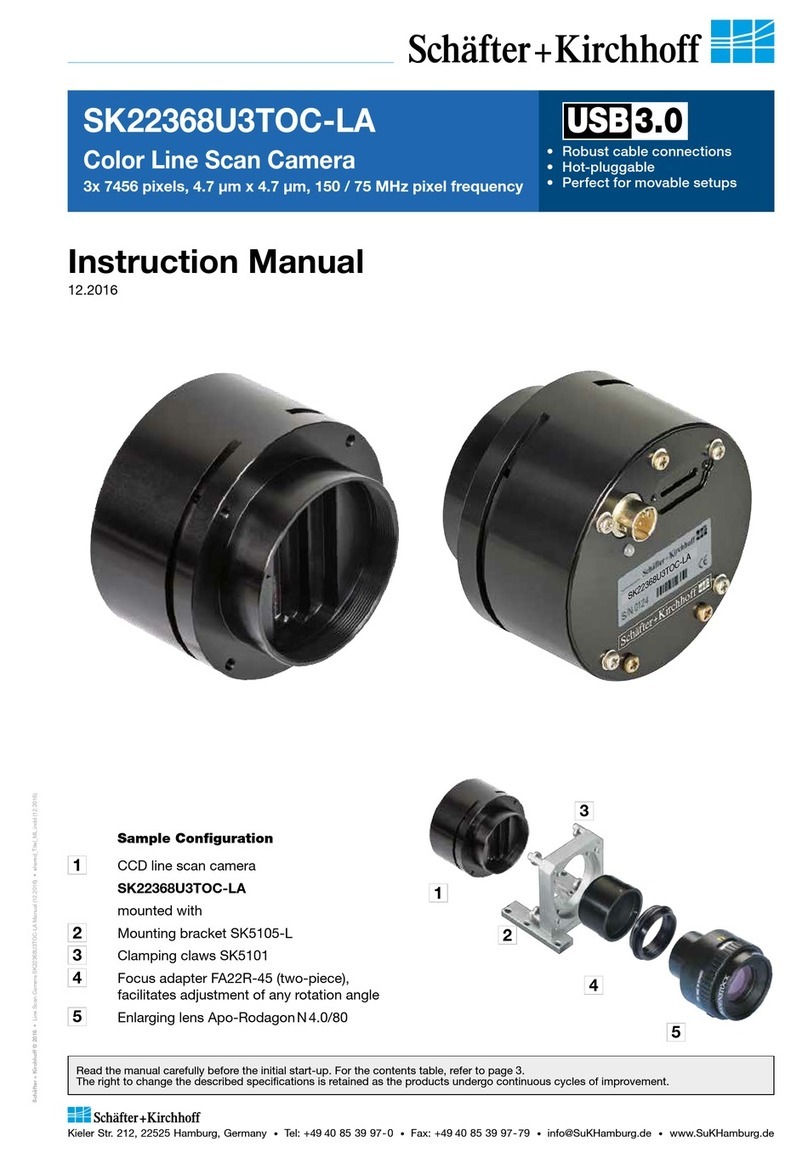

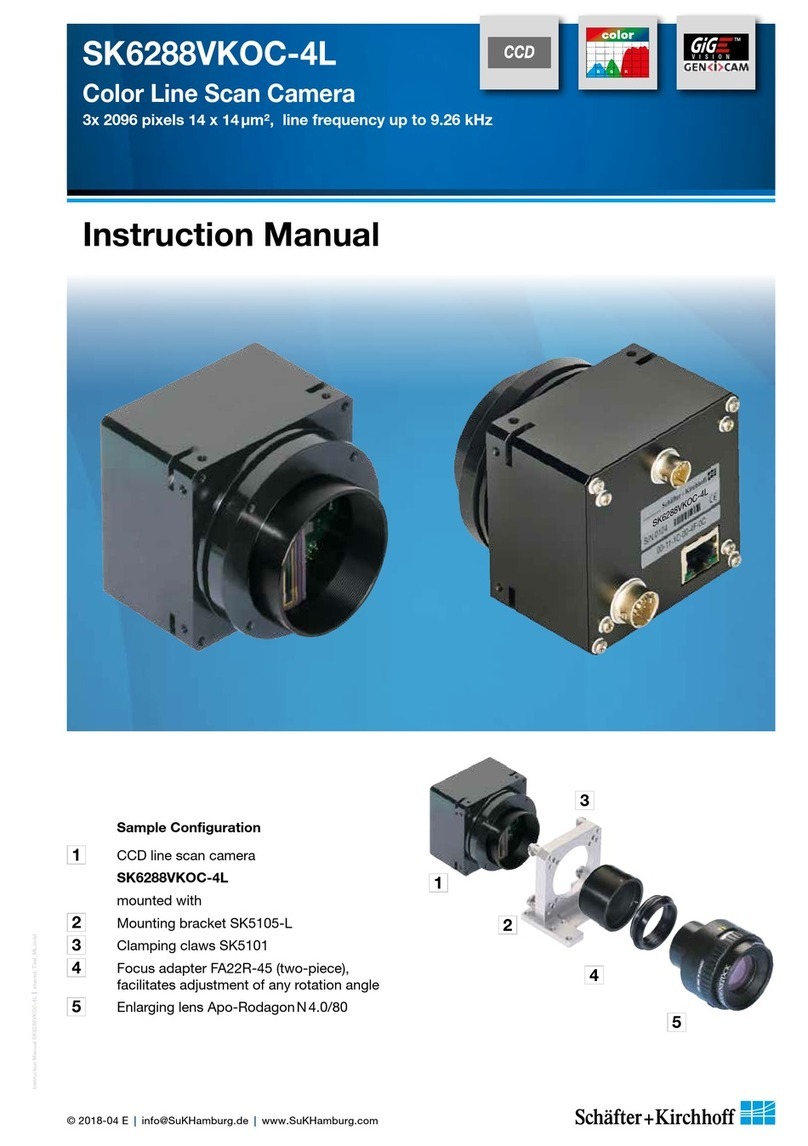

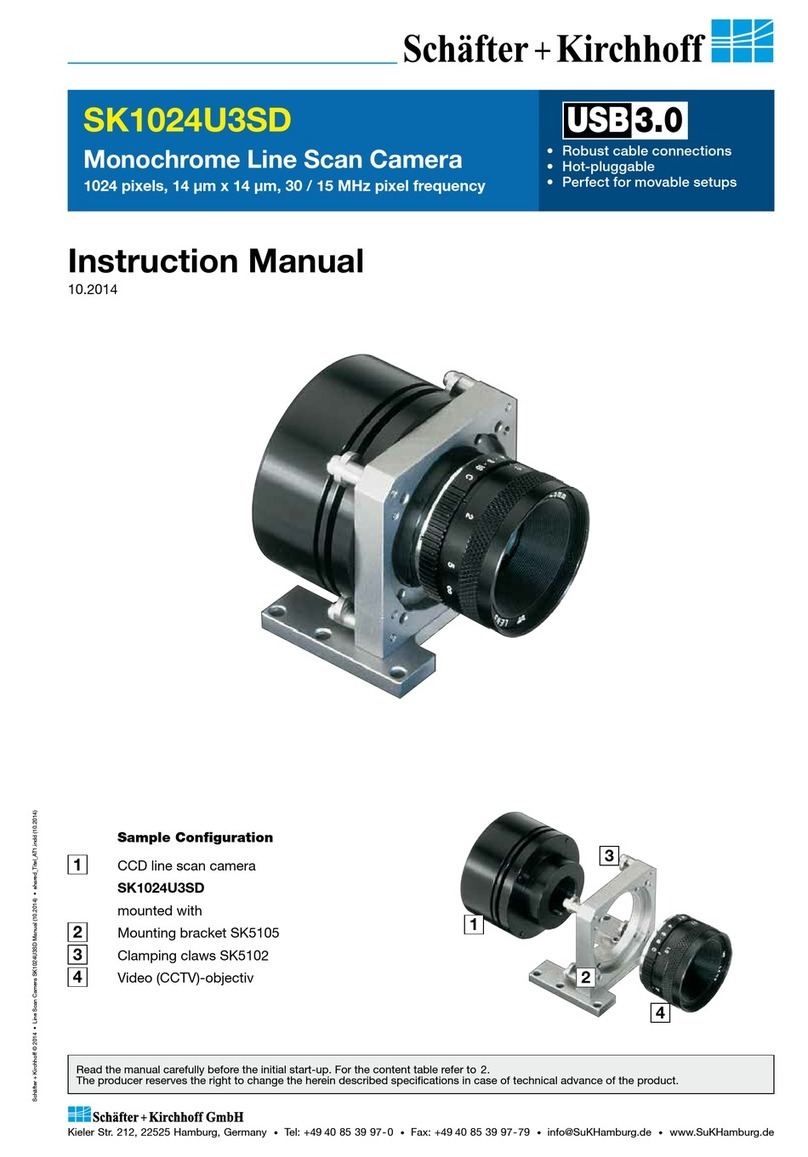

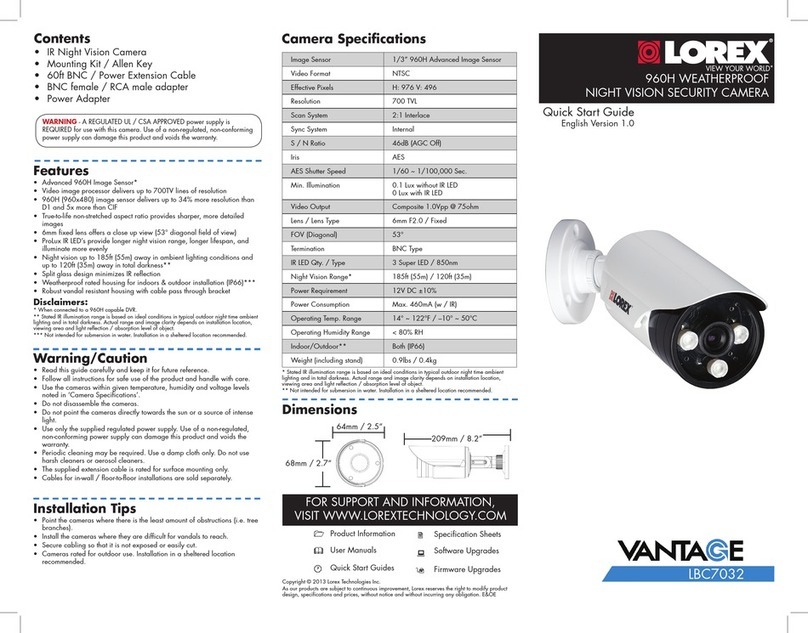

2

1

3

4

5

6

Synchronization and power *

Power: 5.5 W

Socket: Hirose series 10A, male 6-pin

2

Pin Signal Pin Signal

1Line Sync B 4+5 V *

2+15 V * 5Line Sync A

3Frame Sync 6GND

* from external power supply unit

Line Sync A/B and Frame Sync: TTL levels

3Status indicator

off no power, check connection to the external power

supply unit

red power on

green power on, firmware is loaded, camera is ready

• The USB 3.0 interface provides data transfer, camera control and power supply capabilities to the

SK12240U3KOC-LB line scan camera. The operating power can also be fed into socket 2. This is only

mandatory when the camera is operated at 60 MHz or when it is connected to an USB 2.0 interface.

• If you want to operate the camera in FREE RUN trigger mode the connection is completed with the USB 3.0

cable provided the power supply is ensured.

• For any kind of synchronized operation the external trigger signal(s) have to be wired to socket 2in addition.

A frame synchronization signal and two separate line synchronization signals can be handled. The various

trigger modes are particularly described in section Synchronization of the Image Acquisition with the Feed

Rate of the Object (p. 18)

1Data and power

USB 3.0 socket type µB with threaded holes for locking screws