6

2. Installation

2.1 General criteria

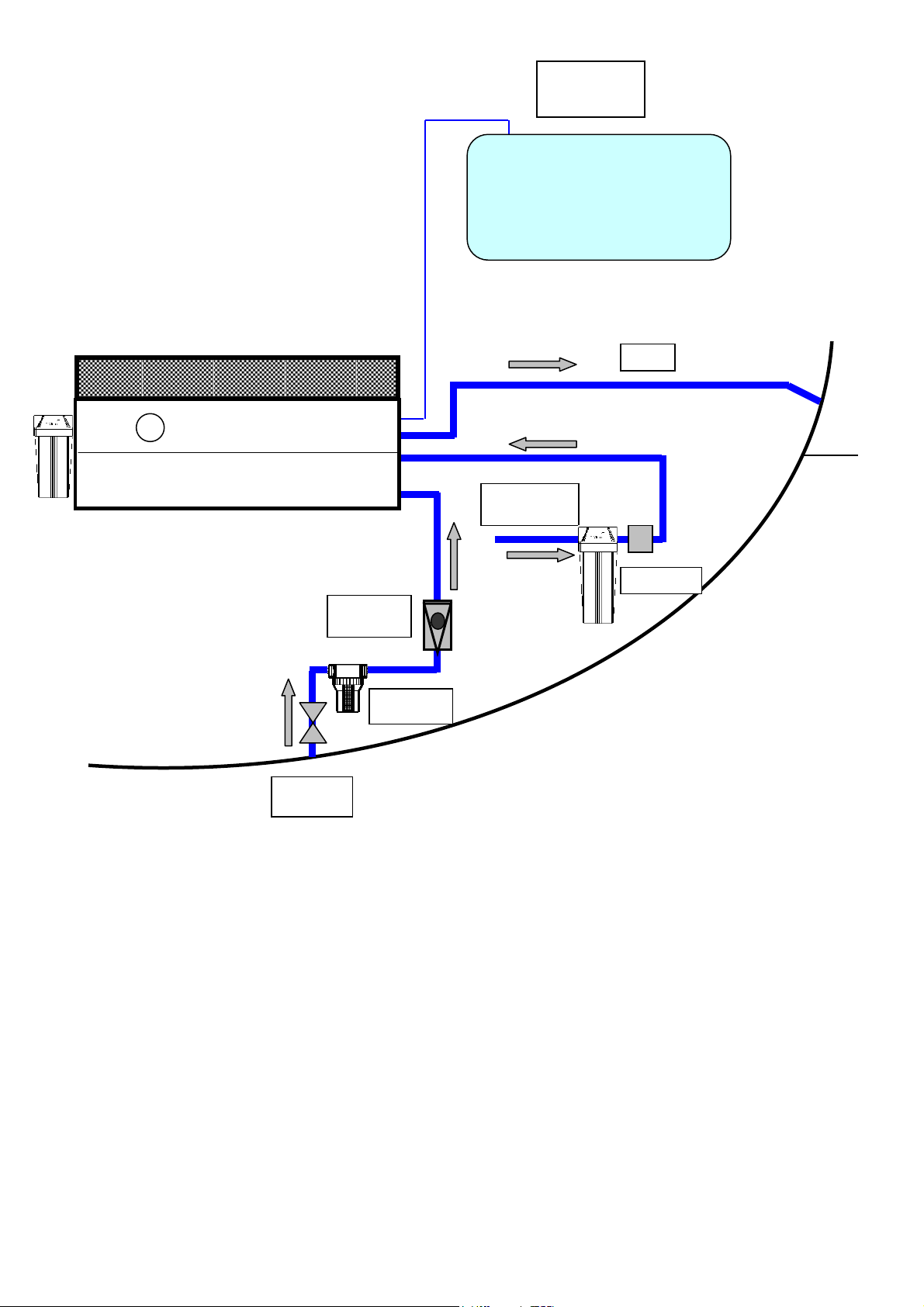

A planned installation will make both fitting and operation of your Ready 60 watermaker easier.

Details below need to be taken into account with your installation:

An appropriate seawater intake with necessary fittings.

Positioning of the watermaker .

Positioning of accessories.

Pipework and cable laying.

A good installation needs to be easy to use, easy to access for maintenance and filter changes. All

Watermaker components have been designed to achieve all of this. Draw a schematic electric and

hydraulic connection diagram when the installation plan is complete and keep it with this manual

for reference.

2. Installation

2.2 Components mounting

Watermaker positioning.

The horizontal and vertical distance of the watermaker, from the sea water inlet, is a critical

aspect of the installation. Even if the pumps are self-priming type, it is strictly adviced to install

the watermaker as low as possible respect the sea level, and as close as possible respect the

sea water intake.

If the watermaker is positioned too much above respect the sea level or too far from the water

inlet, the pumps will have difficult in inhaling water and frequent blocks can occur.

Usually the vertical distance respect the sea level is more critical than the horizontal distance

from the water intake. In example if the unit is positioned below the sea line, a distance from the

water inlet up to 3 meters can be tolerated.

On contrary, if the watermaker is positioned above the sea level, it is recommended a distance

from the water inlet of max 1-2 mts.

Anyway never install the unit above more than 30 cm. respect the sea level.

Avoid locating the unit where a loss of water can cause damage or jeopardize its safety.

Allow sufficient space for access to the casing containing the filter cartridge.

The unit must be installed horizontally on a suitable base strong enough to support its weight.

It may be necessary to create a suitable wooden or fiberglass structure for the unit if an existing

one not available. Avoid installing it on a surface susceptible to vibration.

The unit can be a little noisy in operation. Possible areas for siting are: sink closets, under berth

lockers, wardrobe bases (creating a false floor above it.)

Active carbons filter

The active carbons filter (and the preassembled electro-valve) need to be positioned vertically.

There are not specific restriction regarding the distance from the watermaker. The filter housing

is fixed, by means of Parker type screws, through the bracket supplied. It is necessary to leave

sufficient space below to allow unscrewing replacement of the filter.