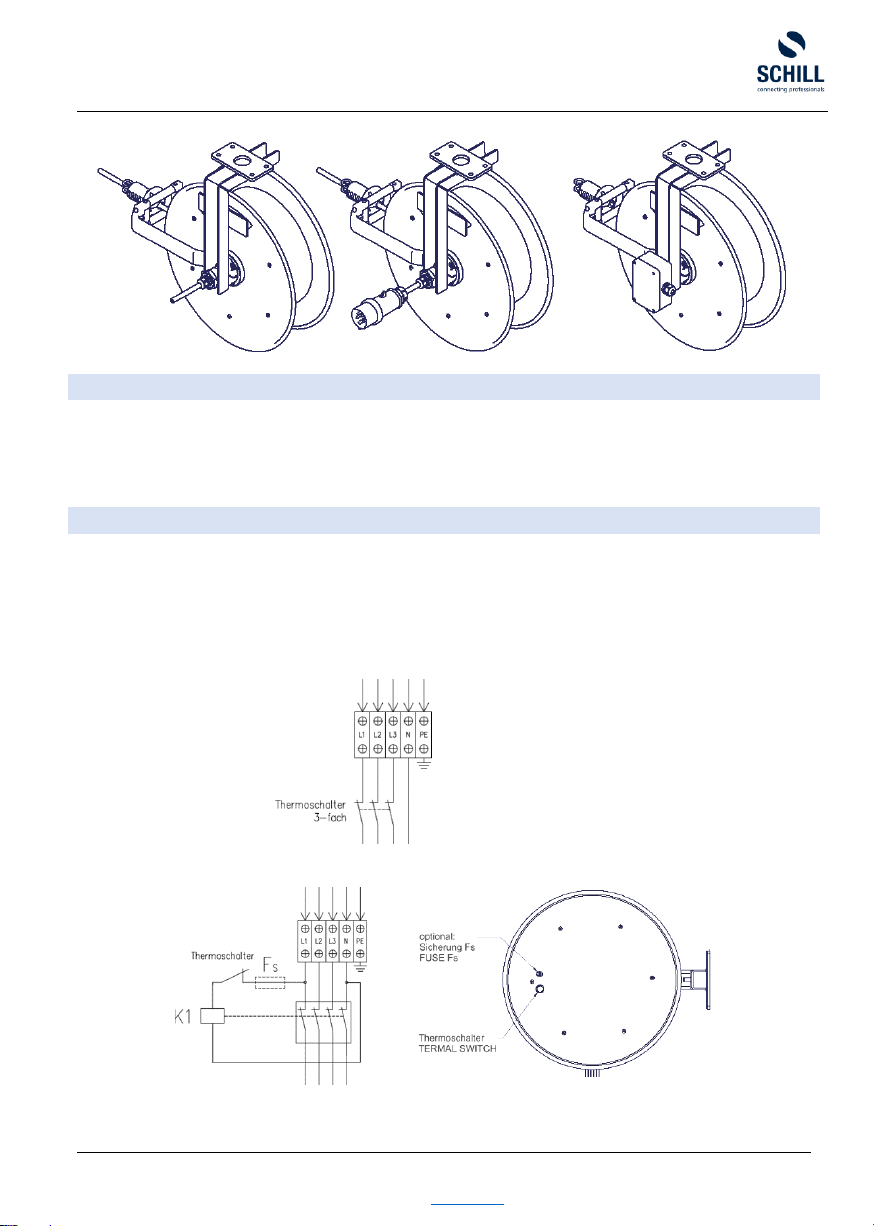

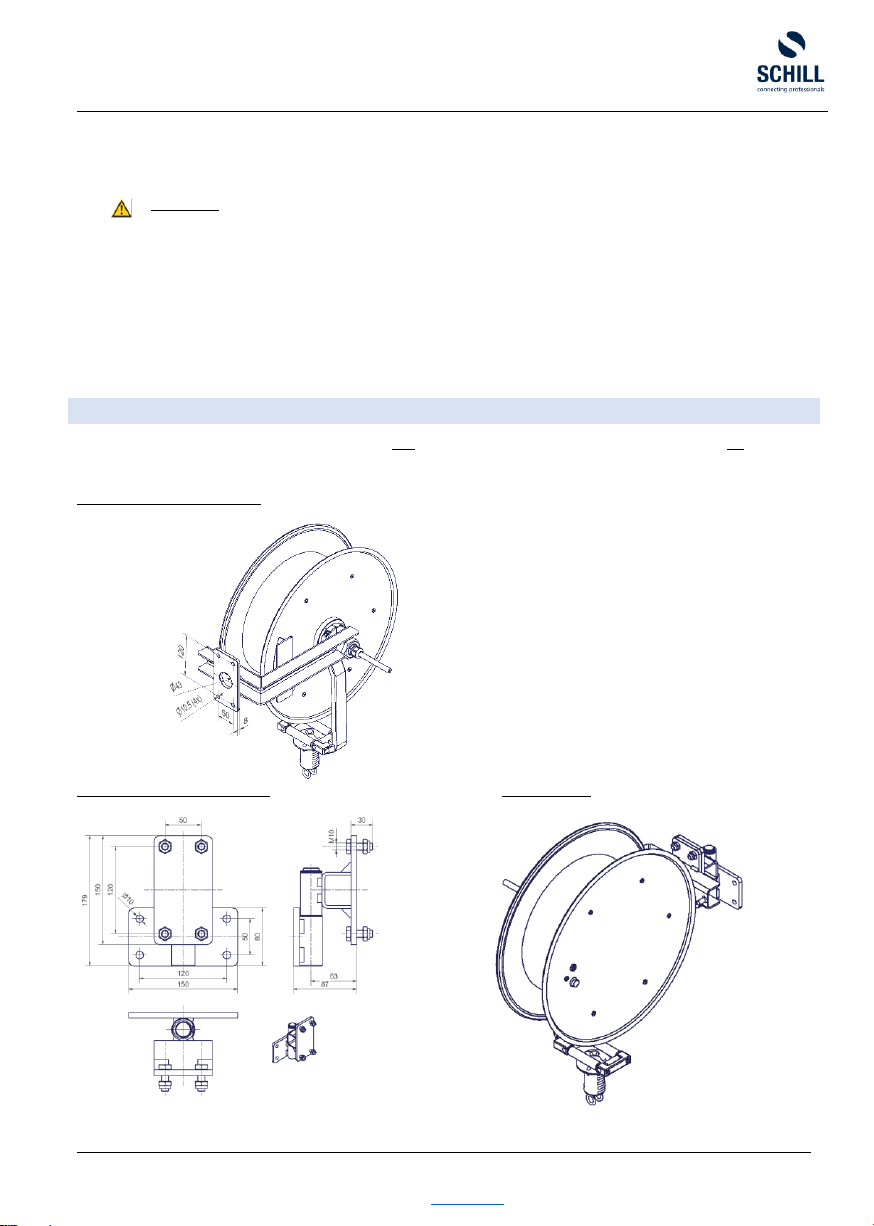

automatic cable rewinder FT / FTE 046

installation and operating instruction

installation and operating instruction FT_FTE 046 - A5 46759000 Seite 2 31.03.2020

Schill GmbH & Co. KG; Bruckstraße 44; 70734 Fellbach www.schill.de

INTRODUCTION

All information necessary for a correct assembly to ensure trouble free operation of the cable reel are described in the present operating

instructions. The warranty given by the manufacturer is only valid if these operating instructions are observed and adhered to. Terms and

conditions are available upon request or at https://www.schill.de/en/footer/general-terms.

Additional user manuals for other product variants can be found at https://www.schill.de/en/downloads or received on request (see

"CONTACT").

GENERAL

Automatic cable rewinder provide for a modern power supply of workstations or the perfect supply of electrical energy, data and signals for

mobile devices. The cable is only pulled out when needed and in the required length. The remainder stays neatly stored on the cable reel

and is protected from contamination and damage. The power connection is always accessible, but never in the way. The cable length can

be easily adapted to a changing work situation. There is no cable chaos, no tripping hazard anymore. If the cable connection is no longer

needed, a short pull on the cable stopper will suffice and the cable will roll up neatly. The automatic cable rewinder provides safety and

order.

HANDLING

The coiled cable should be pulled out to the required length against the spring

tension, but

please refrain from the use of undue force. The

cable is

coiled and fixed in position as described under

"LOCKING DEVICE". The cable should never be pushed in manually. If the cable

becomes entangled when

winding it onto the reel, simply pull the cable out again and then rewind.

MAINTENANCE

The cable reel does not require any

maintenance, due to the excellent antifriction properties of the plastic bearing. However, the cable

must be checked in

regular intervals for damages and replaced

if necessary.

CONTINOUS OPERATION

The cable reel is designed for manual use in

workshops. The standard cable reel is fitted with a standard available cable. If used for

automated applications when a high degree of mobility is required, the standard applied cable has limitations. A special cable with a

support core should be used in those

applications. In order to ensure a reliable function, the cable lengths must be reduced by at least 1/3.

If you consider automated applications, please contact the manufacturer up-front (see “CONTACT”).

SPIRAL SPRING

The

spiral spring is subject to natural wear

and tear and can result in a fatigue fracture of the spring

steel. Based on experience, we

recommend changing the spring after approx.

30.000 operations. The term “operations”

defines not only a complete winding and

unwinding of the spring but

includes

also a partial movement of the spring. For a safe replacement of the coil spring, please refer to

paragraph (“REPLACING THE SPIRAL SPRING”).

SPRING LOAD

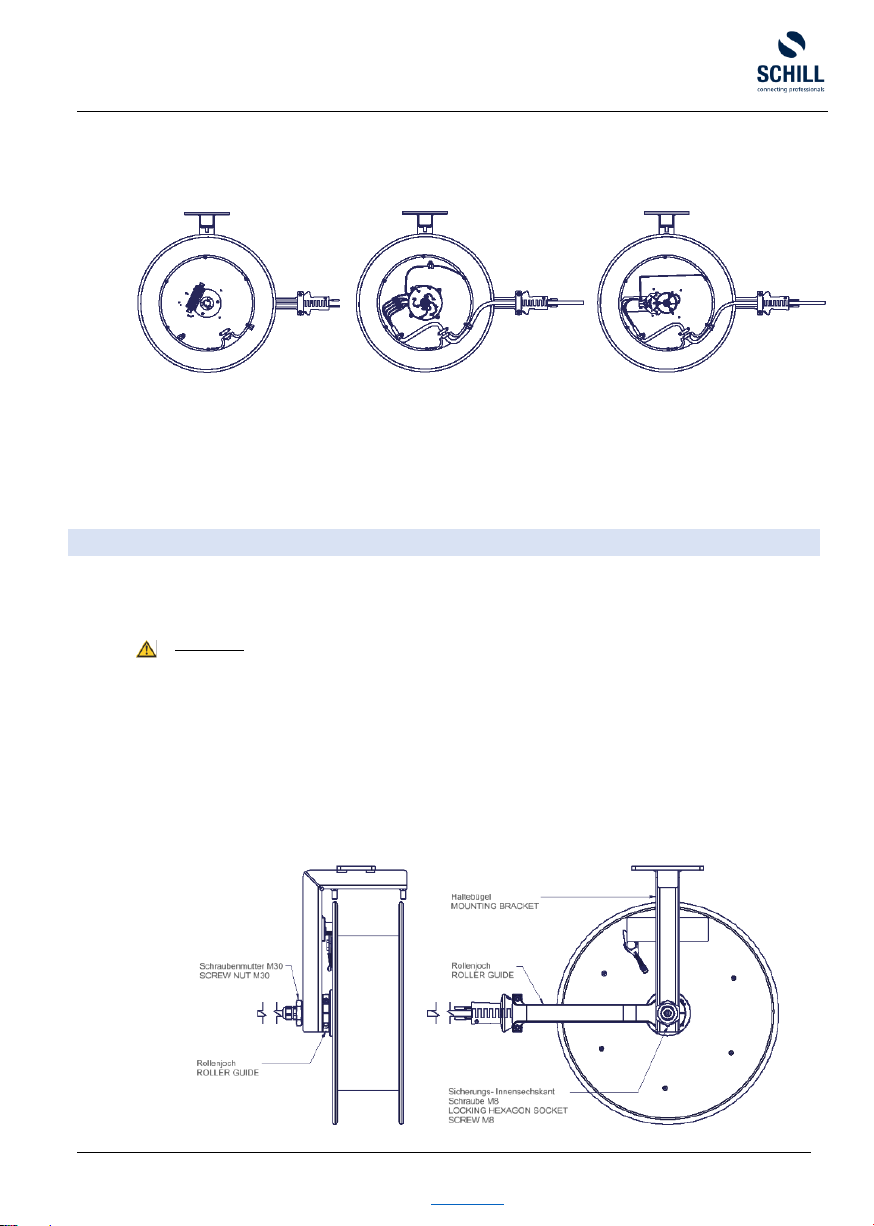

The spring load is set atthe factory. It may become necessary to adjust this setting. Before doing so, the locking device should be engaged.

Then remove the cable stopper and draw the cable out of the roller guide. The load can be increased by additional windings of the cable

anti clockwise and decreased by unwinding the cable in clockwise direction (rewind). Once this hasbeen completed, it is very important that

the cable is fed back through the roller guide and secured with the cable stopper. Increasing the spring load reduces the extractable cable

length. A reduction of the spring load may affect the rewind function of the reel.

ATTENTION

Do not release the cable when rewinding, the tension of the spring can accelerate the winding speed to such a degree that the

swinging cable end could cause injury.

Also damage to the cable and spring could be the result of such an action.