Contents

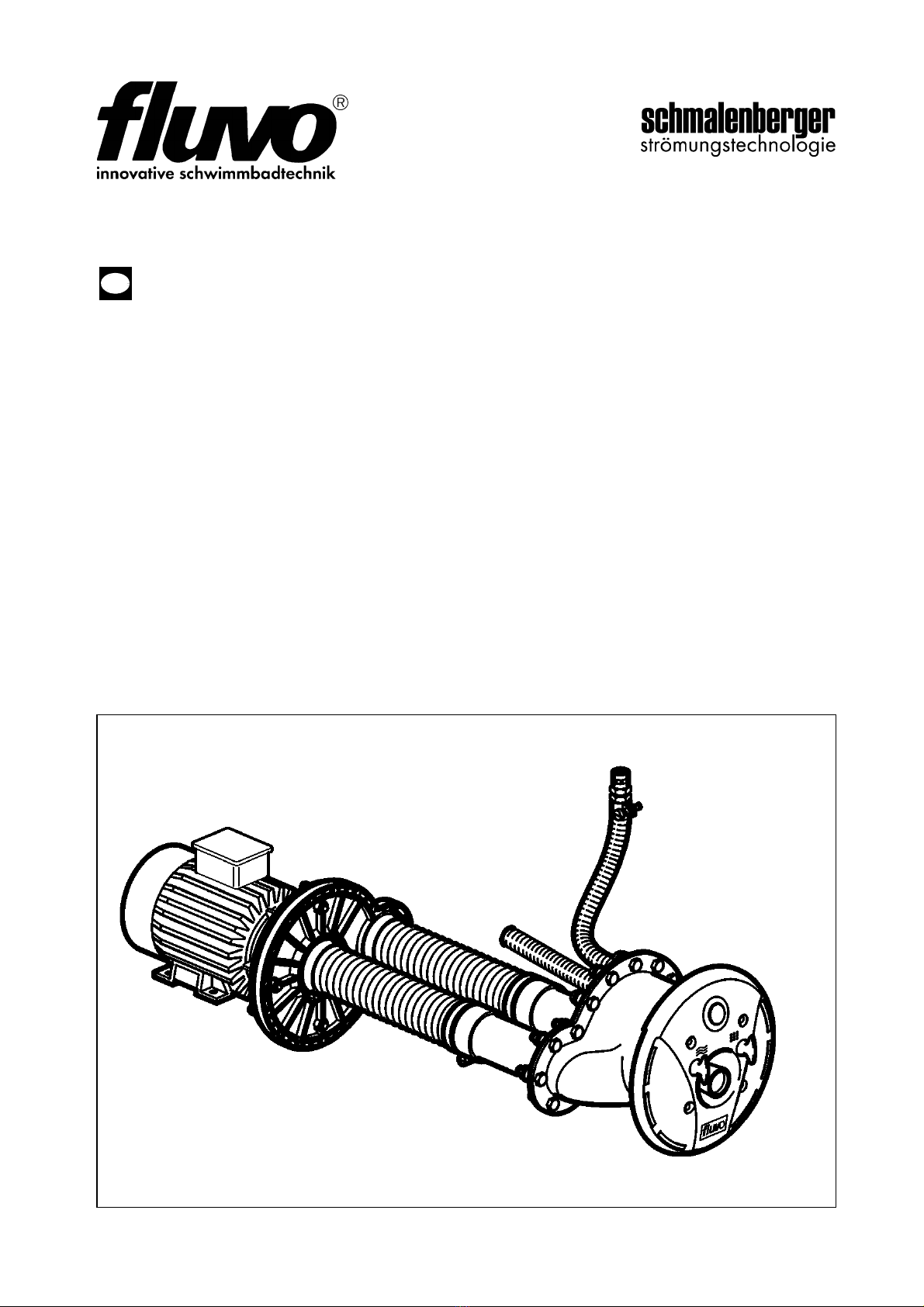

5 0 C2G rondo

Version: 27201 - H

Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

Contents

1 General............................................................................................... 5

1.1 Guarantee notice ............................................................................................................. 5

1.2 General............................................................................................................................ 5

1.3 Usage Instructions........................................................................................................... 5

2 Safety Instructions............................................................................ 5

2.1 General............................................................................................................................ 5

2.2 Symbols........................................................................................................................... 6

3 Unit Description / General Technical Data...................................... 6

3.1 Technical Data................................................................................................................. 6

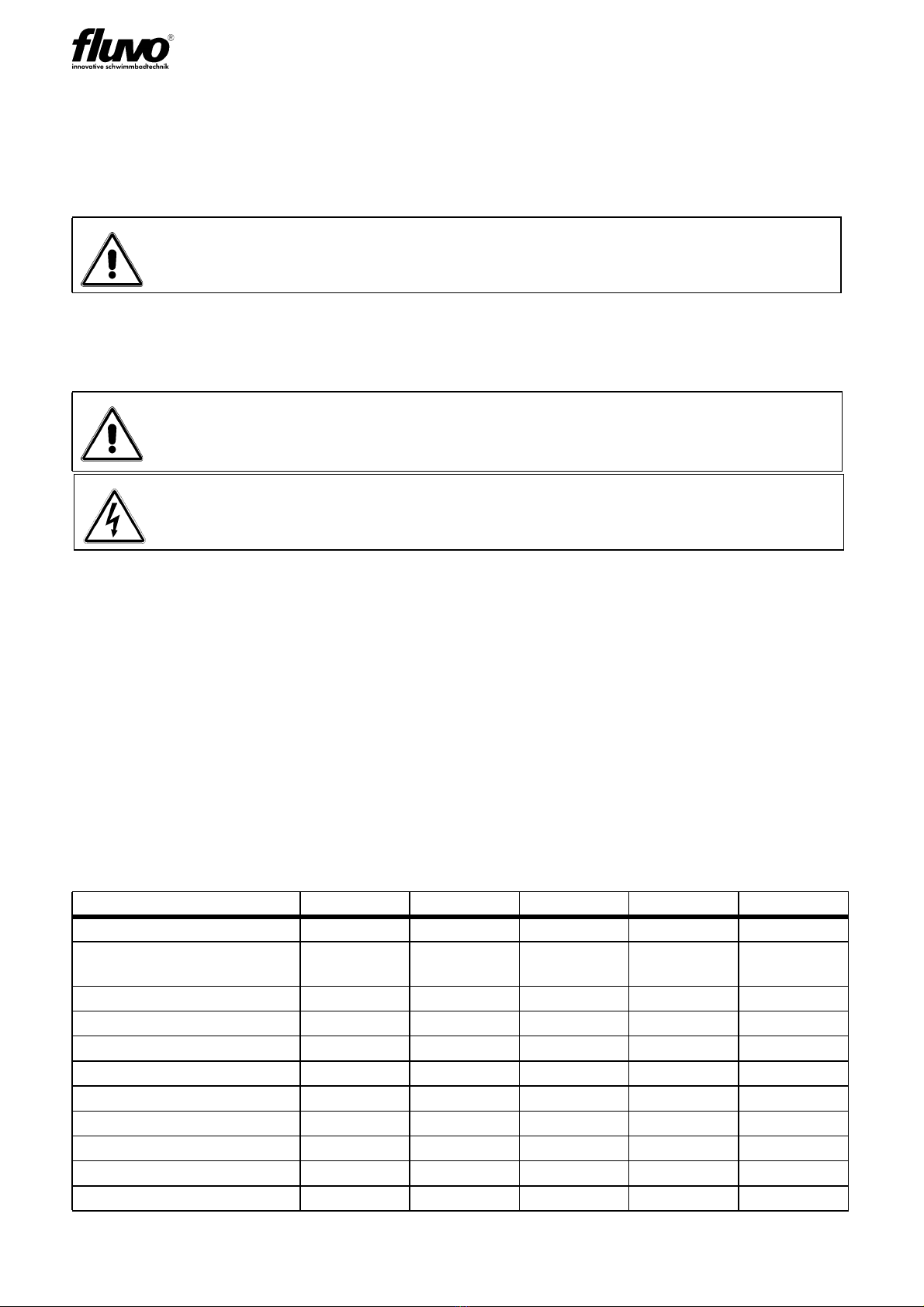

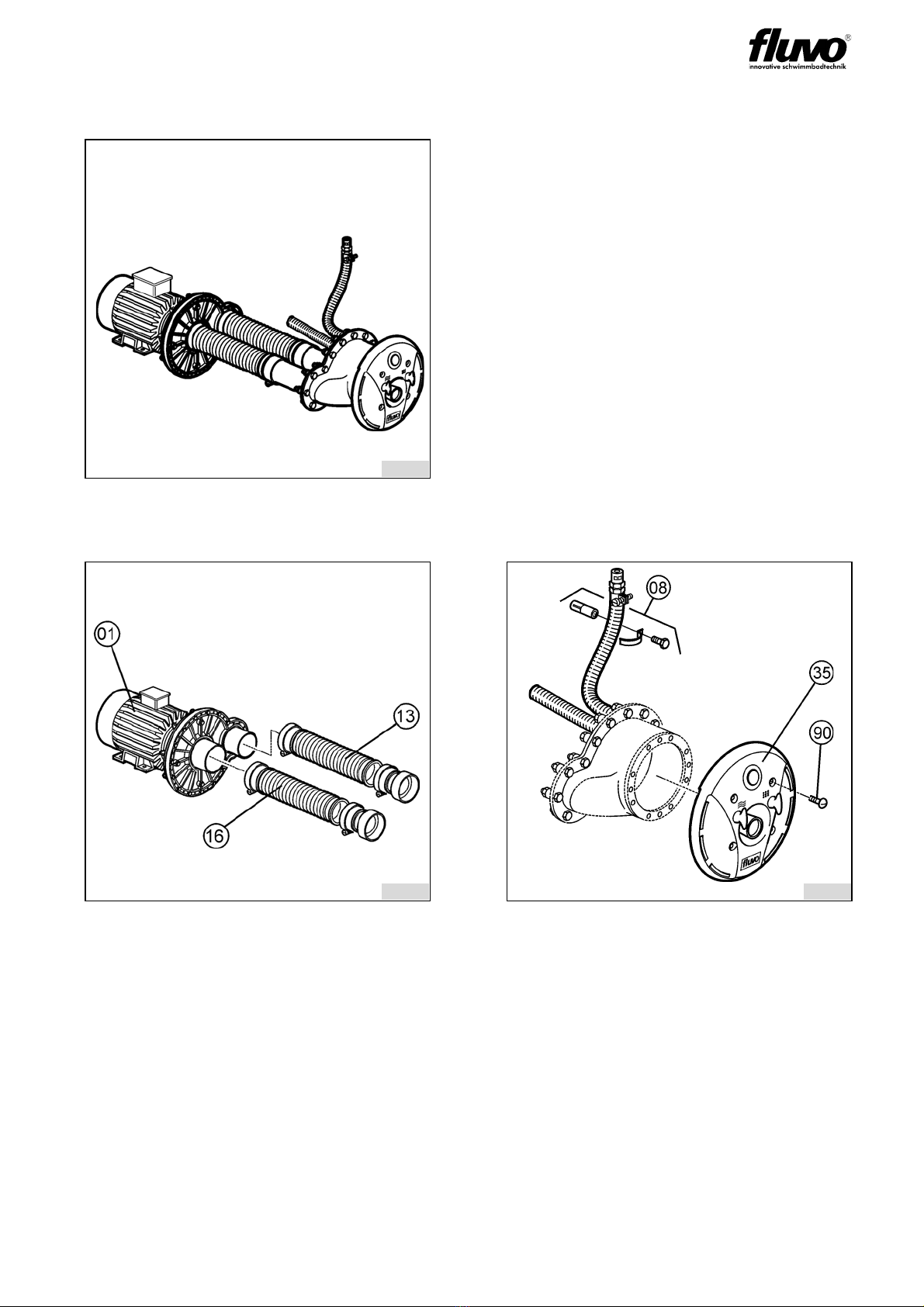

3.2 Device Units..................................................................................................................... 7

4 Installation Site Specifications / Installation .................................. 9

4.1 Base frames for the installation ....................................................................................... 9

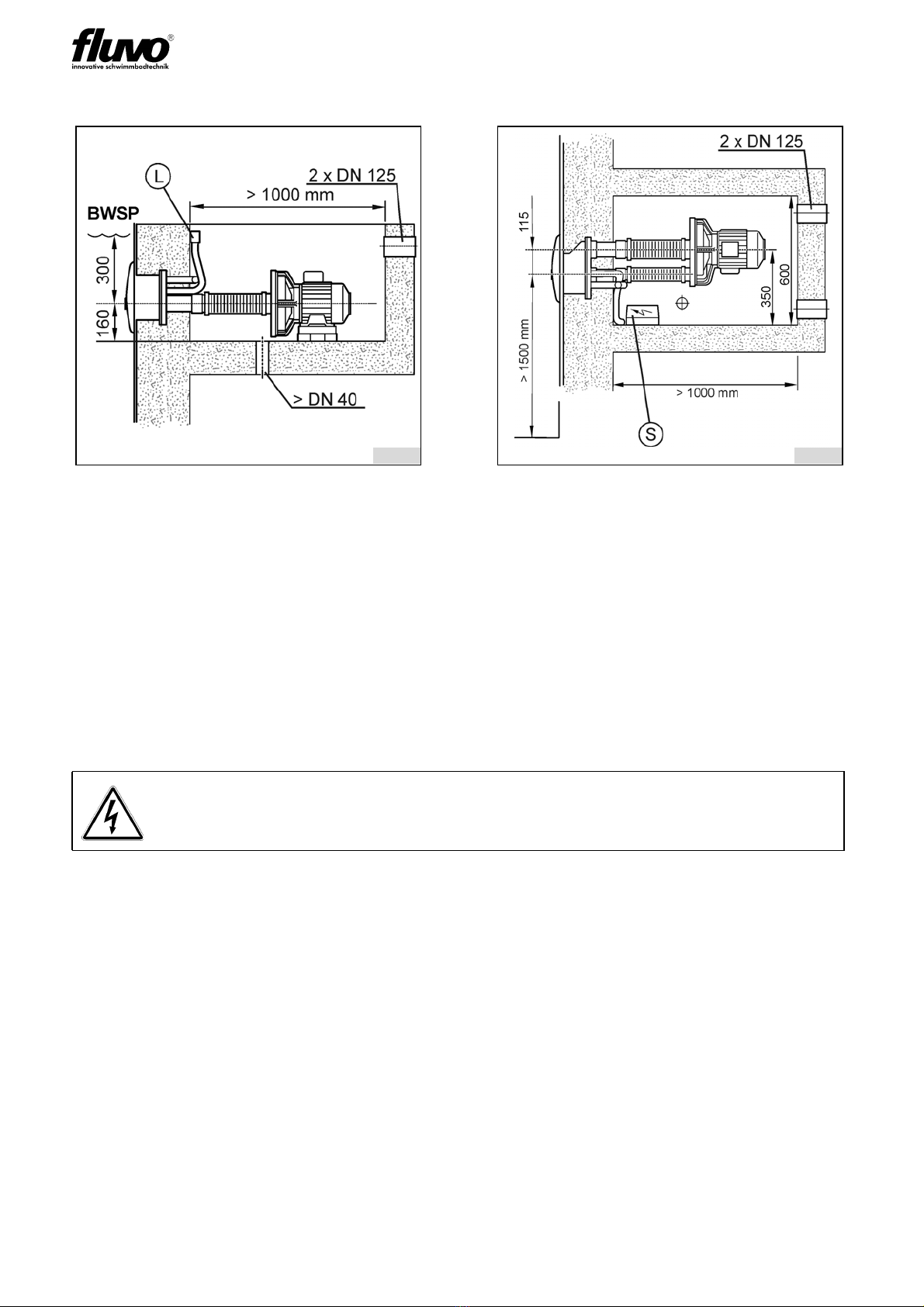

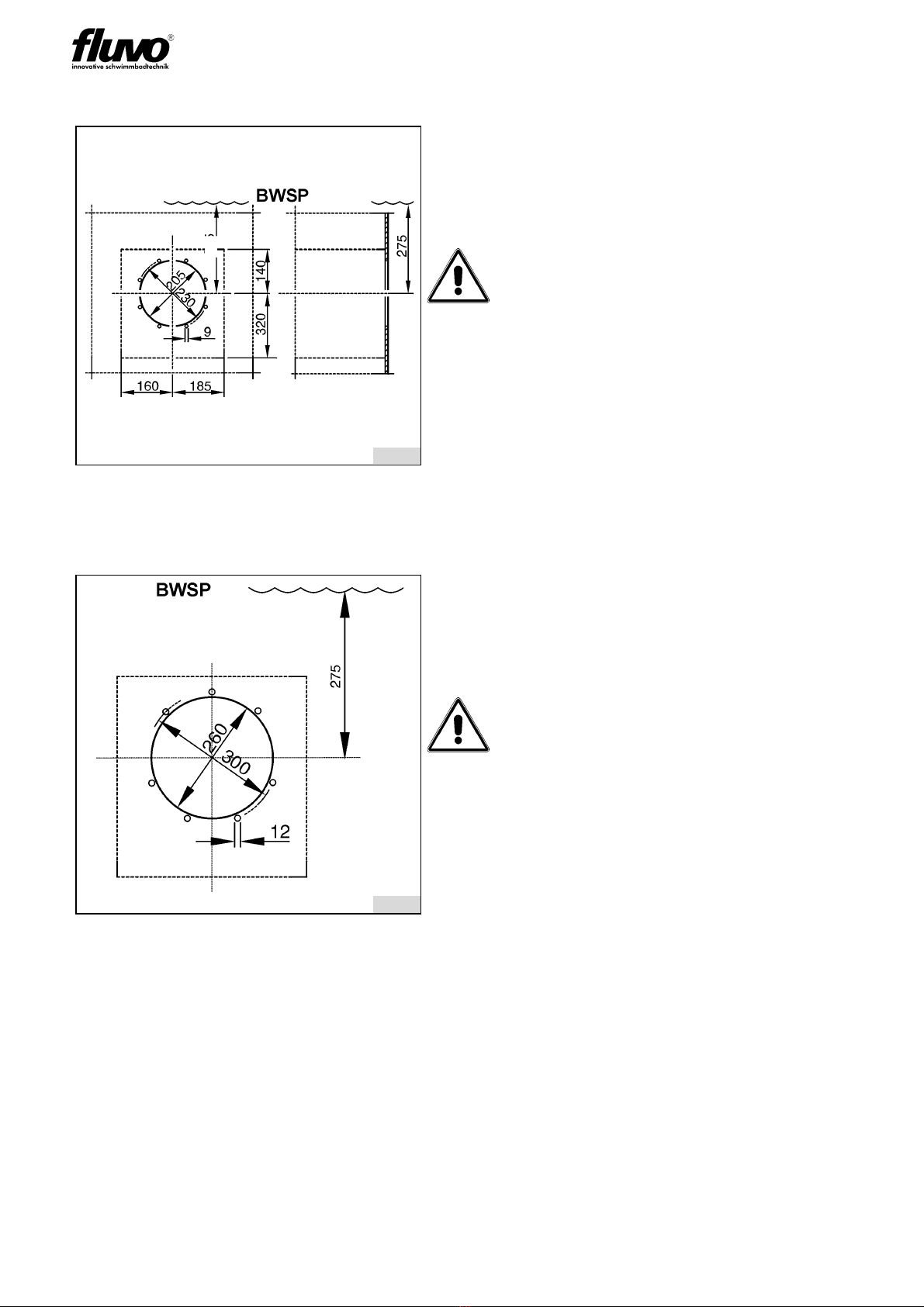

4.2 Planning the pump pit.................................................................................................... 10

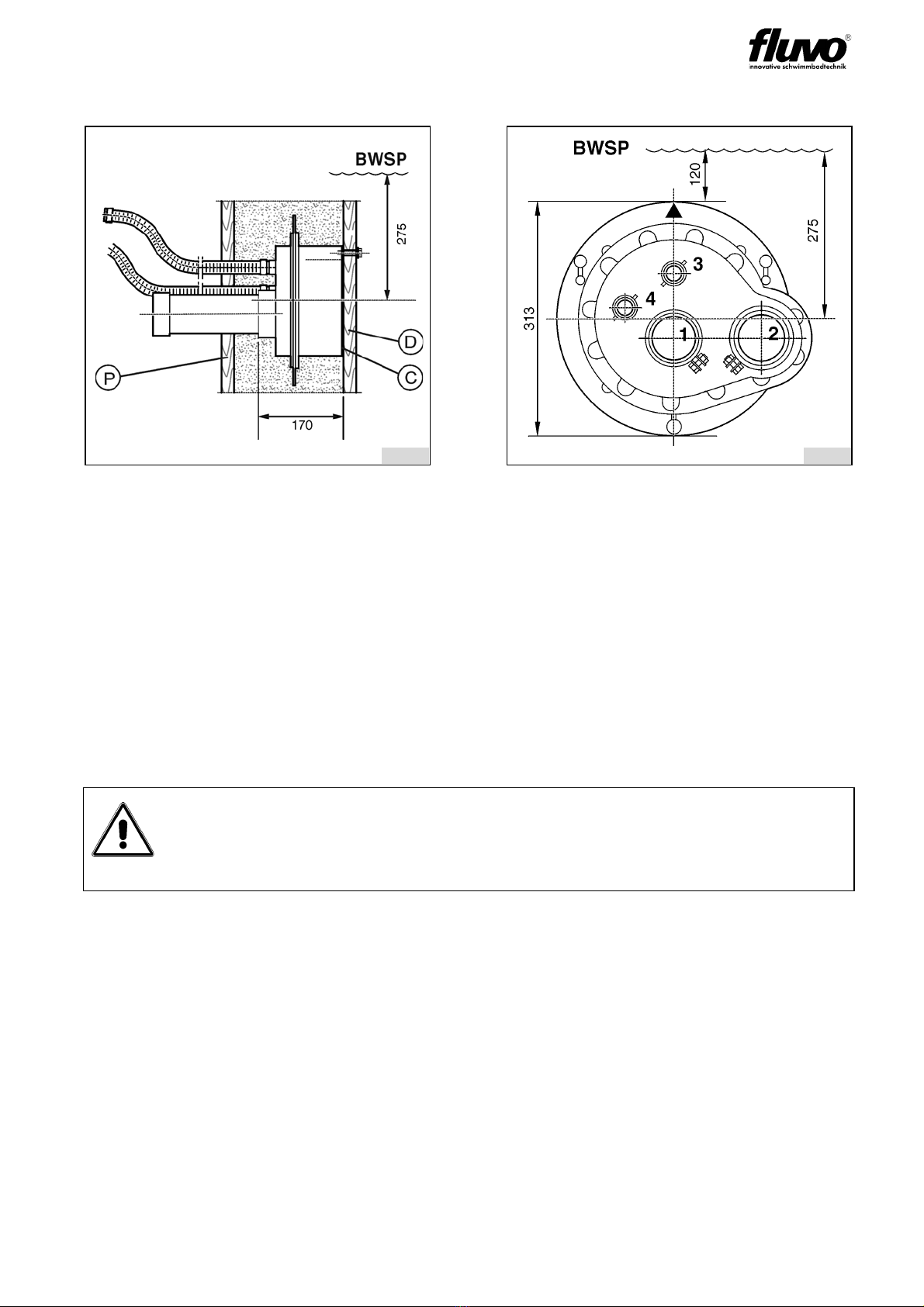

4.3 Installation preparations / Concrete pool ....................................................................... 11

4.4 Installation preparations / Pre-fabricated pool ............................................................... 12

4.5 Installation preparations / Wooden-liner pool ............................................................... 12

4.6 Installation - general ...................................................................................................... 13

4.7 Mounting the installation kit / Pre-fabricated pool.......................................................... 14

4.8 Mounting the installation kit / Wooden-liner pool ........................................................... 15

4.9 Pump Kit Installation...................................................................................................... 16

4.10 Connection to the pool................................................................................................... 16

4.11 Connection to the pump................................................................................................. 17

4.12 Installing the switchgear cabinet.................................................................................... 17

4.13 Non-return air valve installation ..................................................................................... 18

4.14 Installation of the face plate assembly - general............................................................ 18

5 Electrical connections.................................................................... 19

5.1 Electrical Connections - general.................................................................................... 19

5.2 Electrical connections AC ............................................................................................. 20

5.3 Electrical connections three-phase current.................................................................... 20

6 Start-up / Operating ........................................................................ 21

7 Fault Assistance ............................................................................. 22

8 Shutdown / Overwintering.............................................................. 23

8.1 Empty the pool............................................................................................................... 23

8.2 Face plate assembly overwintering ............................................................................... 23

8.3 Draining the pump ......................................................................................................... 23

9 Maintenance and Repair................................................................. 24

9.1 General.......................................................................................................................... 24

9.2 Maintenance .................................................................................................................. 24

9.3 Repairs .......................................................................................................................... 24

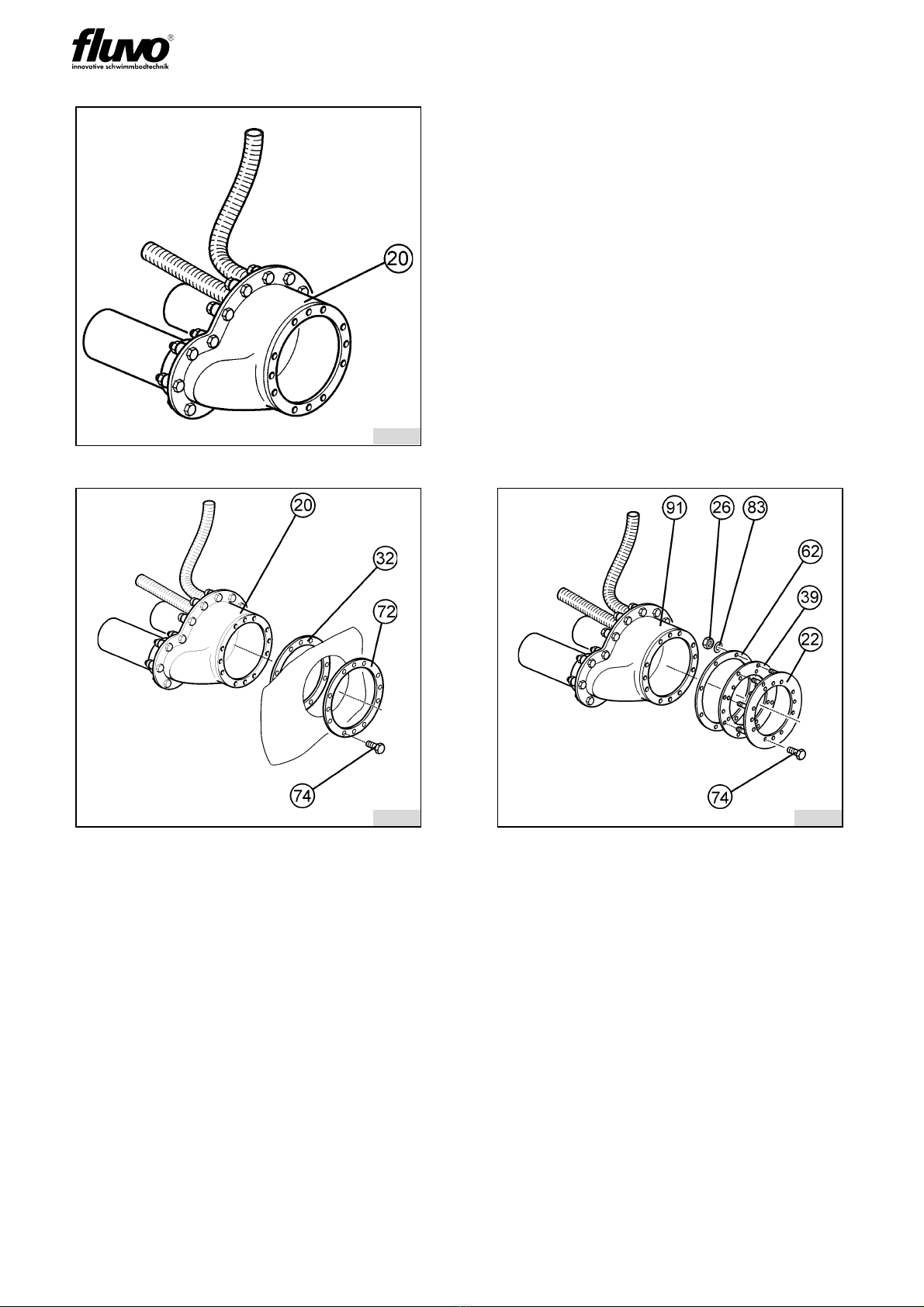

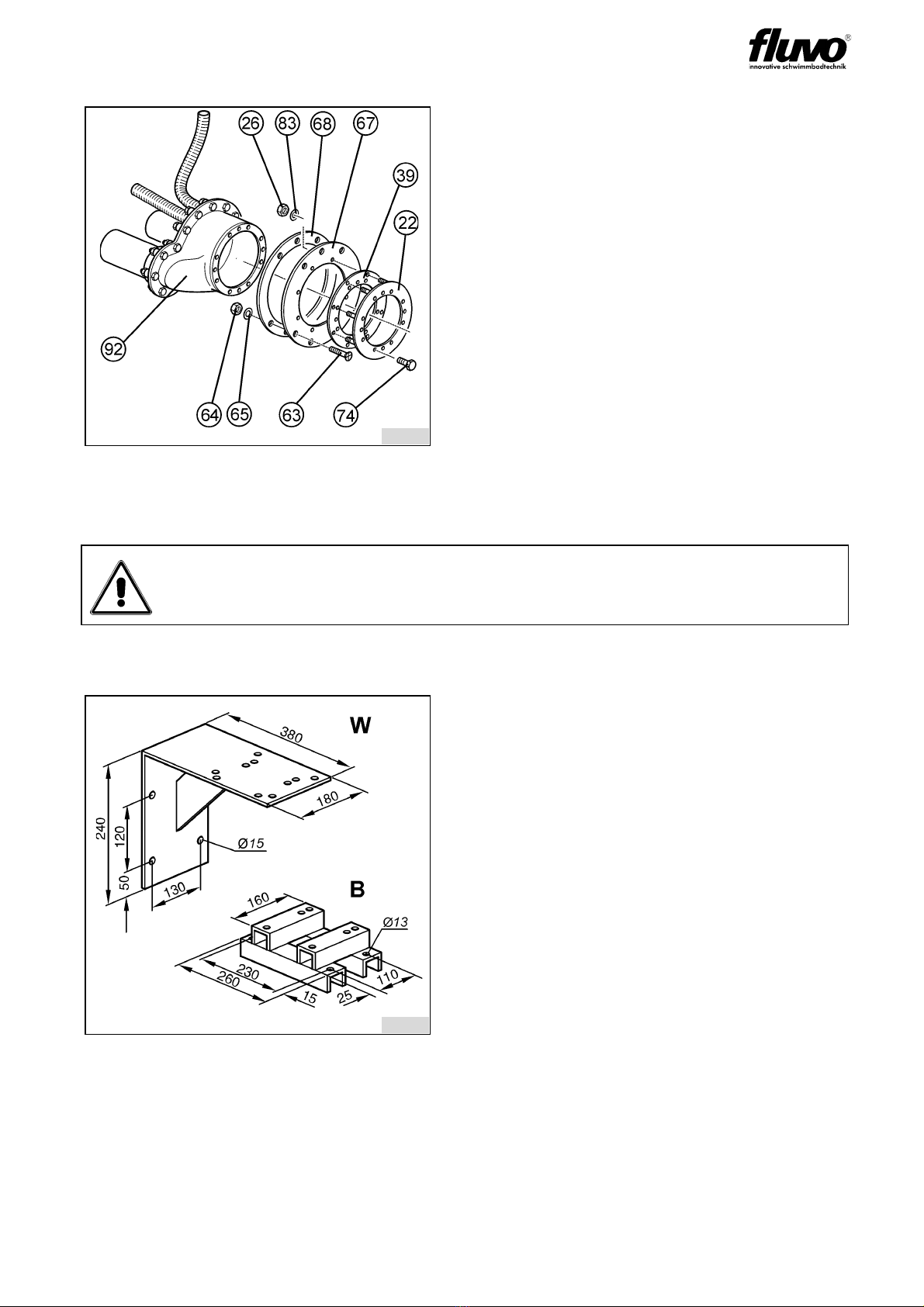

10 Spare parts ...................................................................................... 24

11 Spare Parts List and Drawing ....................................................... 121

11.1 Spare Parts List ............................................................................................................121