Contents

VSi-…/VSi-…-D vacuum/pressure switch

www.schmalz.com

1Safety Instructions...............................................................................................5

1.1 Classification of safety instructions ...................................................................................5

1.2 Warnings ...........................................................................................................................6

1.3 Mandatory symbols ...........................................................................................................6

1.4 General safety instructions................................................................................................7

1.5 Intended use......................................................................................................................8

1.6 Requirement for the user...................................................................................................8

2Product Description.............................................................................................9

2.1 General description ...........................................................................................................9

2.2 Versions.............................................................................................................................9

2.3 VSi design (without display)............................................................................................10

2.4 VSi design … D (with display) .........................................................................................10

3Technical Data..................................................................................................11

3.1 General data....................................................................................................................11

3.2 Electrical data..................................................................................................................11

3.3 Mechanical data ..............................................................................................................12

3.4 Factory settings...............................................................................................................12

4Installation and commissioning .........................................................................13

4.1 Assembly.........................................................................................................................13

4.2 Electrical connection .......................................................................................................13

4.2.1 Pin assignment, M8 connector /M12 connector..............................................................15

4.3 IO-Link commissioning....................................................................................................15

5Interfaces ..........................................................................................................16

5.1 Digital switching outputs (SIO)........................................................................................16

5.2 IO-Link.............................................................................................................................16

5.2.1 Configuration server........................................................................................................17

5.3 NFC.................................................................................................................................17

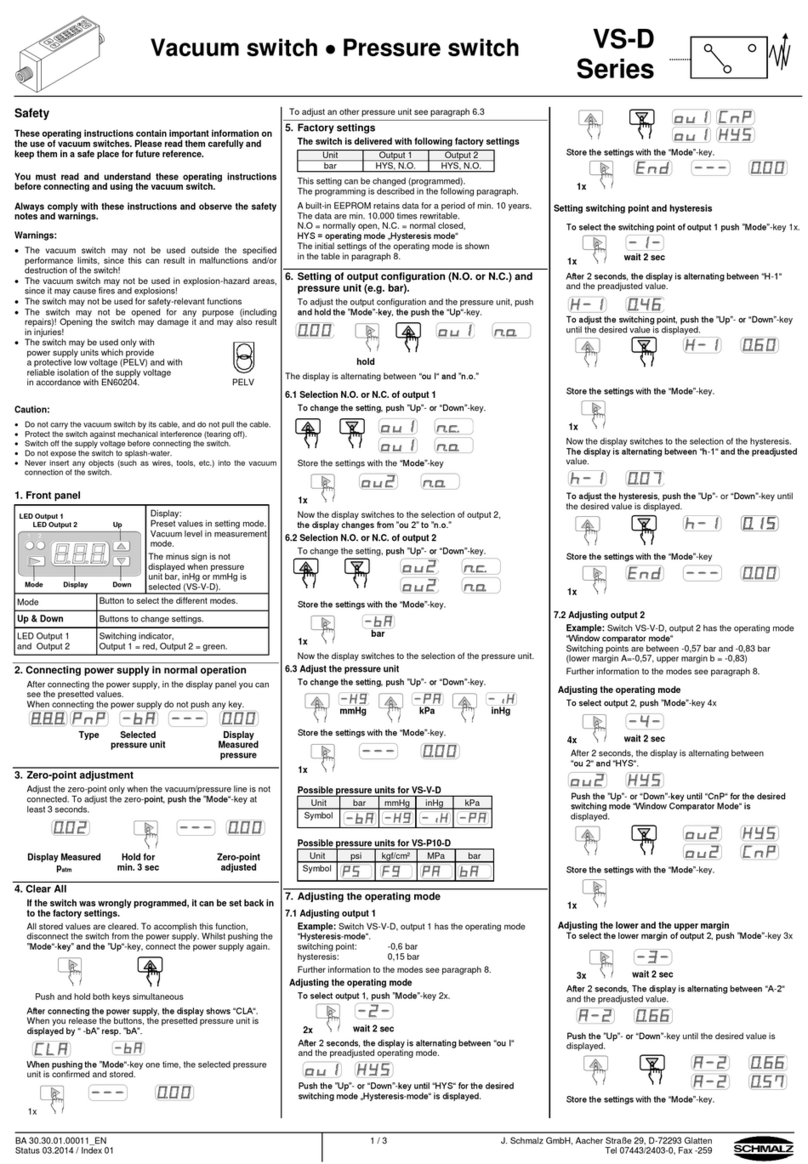

6Manual operation of the display version............................................................18

6.1 Operating concept...........................................................................................................18

6.1.1 Display of vacuum and pressure values .........................................................................18

6.1.2 Navigating in the menu....................................................................................................19

6.1.3 Editing the parameters ....................................................................................................19

6.1.4 Entering the PIN code .....................................................................................................21

6.1.5 Automatically quitting the menu ......................................................................................21

6.2 Basic menu......................................................................................................................22

6.3 Extended functions (EF)..................................................................................................23

6.4 Info (INF) .........................................................................................................................24

6.5 Displaying the basic settings (slide show).......................................................................25

7Function description..........................................................................................26

7.1 Overview..........................................................................................................................26