Contents

EN-US · 30.30.01.03279 · 01 · 12/22 3 / 36

Contents

1Important Information ...................................................................................................................................5

1.1 Note on Using this Document.............................................................................................................5

1.2 The technical documentation is part of the product ........................................................................5

1.3 Type Plate.............................................................................................................................................5

1.4 Symbols.................................................................................................................................................6

2Fundamental Safety Instructions................................................................................................................... 7

2.1 Intended use ........................................................................................................................................7

2.2 Non-Intended Use................................................................................................................................7

2.3 Personnel Qualification ....................................................................................................................... 7

2.4 Warnings in This Document ................................................................................................................ 7

2.5 Residual Risks .......................................................................................................................................8

2.6 Modifications to the Product .............................................................................................................. 8

3Product description......................................................................................................................................... 9

3.1 General Description ............................................................................................................................. 9

3.2 Versions ................................................................................................................................................9

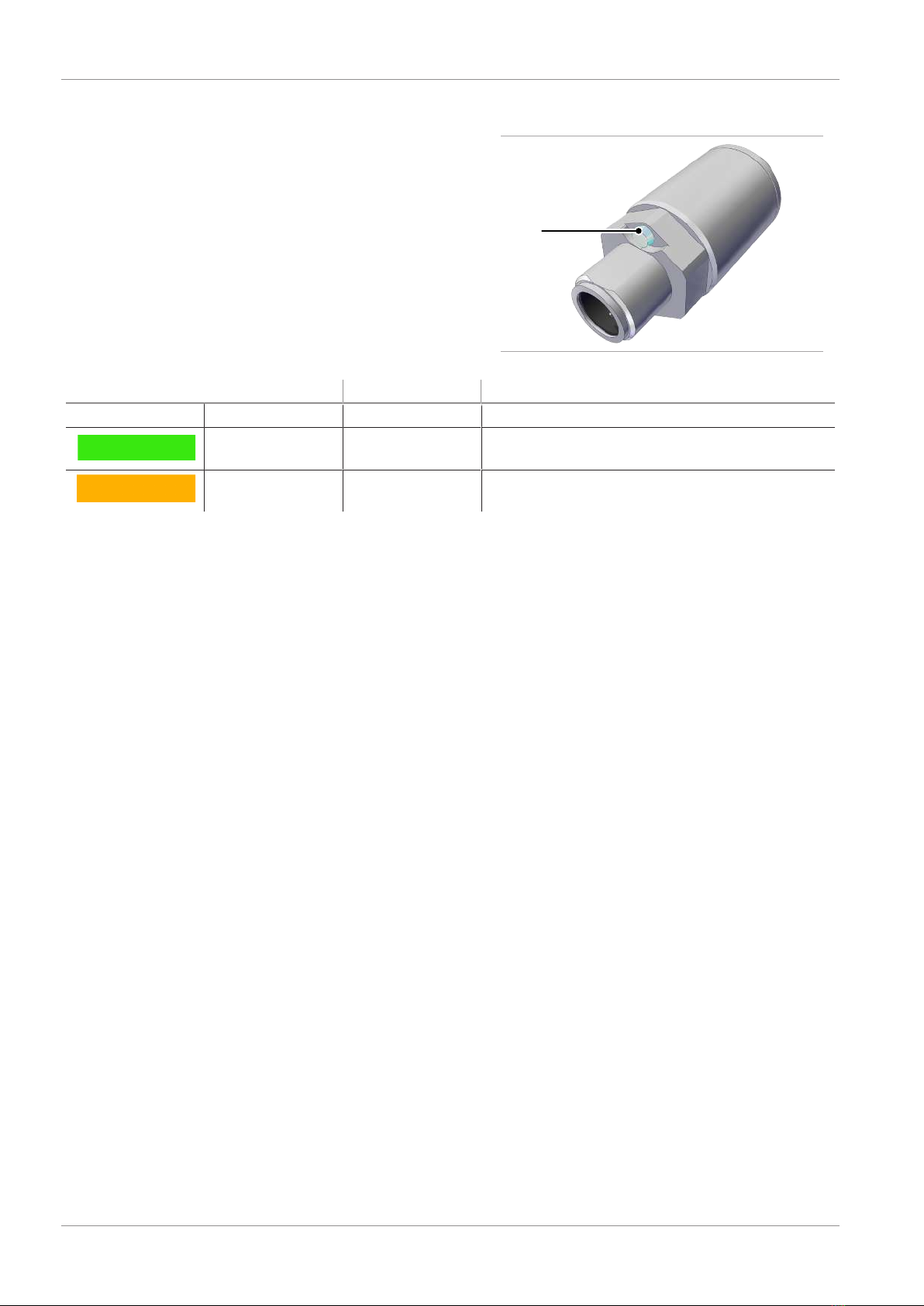

3.3 Design of the VSi HD ...........................................................................................................................9

3.4 LED Status Display..............................................................................................................................10

4Technical Data...............................................................................................................................................11

4.1 General Data ...................................................................................................................................... 11

4.2 Electrical Data ....................................................................................................................................11

4.3 Mechanical Data ................................................................................................................................11

4.4 Factory Settings..................................................................................................................................12

5Installation ....................................................................................................................................................13

5.1 Mounting ...........................................................................................................................................13

5.2 Electrical Connection ......................................................................................................................... 13

6IO-Link Commissioning................................................................................................................................. 15

7Interfaces.......................................................................................................................................................16

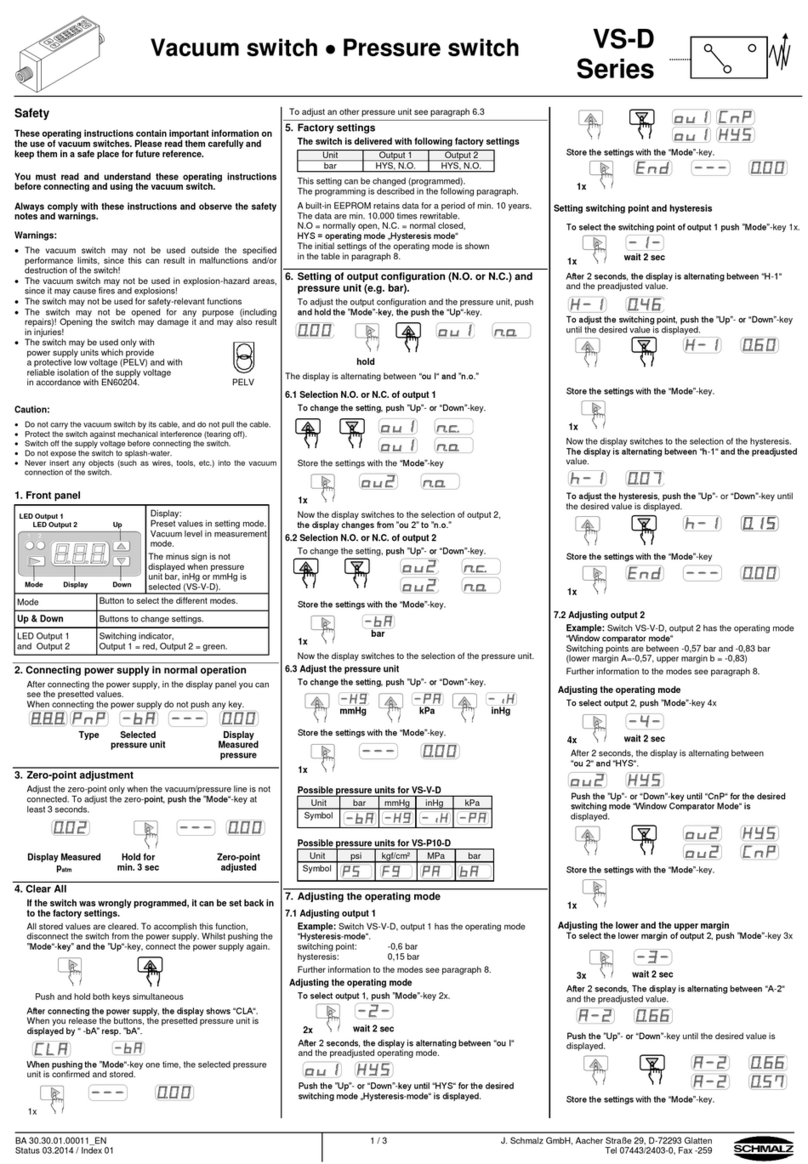

7.1 Digital Switching Outputs (SIO) ........................................................................................................ 16

7.2 IO-Link ................................................................................................................................................16

7.3 Replacement of the Device with a Parameterization Server ..........................................................17

8Description of Functions ..............................................................................................................................18

8.1 Overview of Functions.......................................................................................................................18

8.2 Measuring Vacuum............................................................................................................................19

8.3 Monitoring the Operating Voltage .................................................................................................. 19

8.4 Switching Points.................................................................................................................................19

8.5 Teach-in for Switching Points ...........................................................................................................21

8.6 Additional Switching Point Settings.................................................................................................22

8.7 Access Rights ......................................................................................................................................22

8.8 Device Identification..........................................................................................................................23

8.9 System Monitoring and Diagnostics ................................................................................................. 24

8.10 System Commands ............................................................................................................................. 25

8.10.2 Zero-Point Adjustment (Calibration)....................................................................................25