Contents

4 / 94 EN-US · 30.30.01.02237 · 00 · 04/20

6 Component Functions...................................................................................................................................44

6.1 Overview of Functions ......................................................................................................................... 44

6.2 Bus Module Functions .......................................................................................................................... 45

6.2.1 System Commands (0x0002)......................................................................................................45

6.2.2 Device Identification ................................................................................................................. 46

6.2.3 User-Specific Localization..........................................................................................................48

6.2.4 Access Rights: PIN Code for NFC Write Protection (0x005B) ................................................... 49

6.3 Device Status of the Whole Terminal SCTSi........................................................................................ 49

6.3.1 Device Monitoring (Determination of the Required System Parameters) ............................. 50

6.3.2 Device Diagnostics ..................................................................................................................... 53

6.4 Ejector SCPSt Functions ........................................................................................................................ 59

6.4.1 Switching Points (0x0064 to 0x0067)........................................................................................ 59

6.4.2 Control Functions (0x006D).......................................................................................................60

6.4.3 Blow-Off Function (0x006E) ...................................................................................................... 61

6.4.4 Set Permitted Evacuation Time t1 (0x006B)............................................................................. 62

6.4.5 Set Permitted Leakage (0x006C)............................................................................................... 63

6.4.6 Counters (0x008C, 0x008D, 0x008F, 0x0090)............................................................................ 63

6.4.7 Manual Operation of the Ejectors............................................................................................ 64

6.4.8 Changing the Blow-Off Flow Rate on the Ejector................................................................... 65

6.5 IO-Link Master Functions ..................................................................................................................... 66

6.5.1 Process Data Management ....................................................................................................... 66

6.5.2 IO-Link Port Configuration ....................................................................................................... 66

6.5.3 IO-Link ISDU – data management (read/write parameter data of IO-Link devices).............. 72

6.6 DI Module Functions ............................................................................................................................ 76

7 Transport and Storage..................................................................................................................................78

7.1 Checking the Delivery .......................................................................................................................... 78

7.2 Removing the Packaging ..................................................................................................................... 78

7.3 Reusing the Packaging......................................................................................................................... 78

8 Installation.....................................................................................................................................................79

8.1 Installation Instructions........................................................................................................................ 79

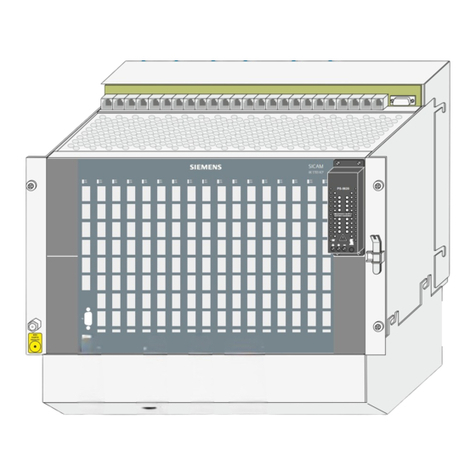

8.2 Mounting .............................................................................................................................................. 79

8.3 Connecting the Compressed Air and Vacuum.................................................................................... 80

8.3.1 Recommended Line Cross Sections (Internal Diameters) in mm............................................. 80

8.4 Electrical Connection............................................................................................................................ 81

8.4.1 Instructions for Start of Operations ......................................................................................... 82

8.4.2 Bus module ................................................................................................................................ 82

8.4.3 IOL Master Module.................................................................................................................... 83

8.4.4 DI module................................................................................................................................... 84

9 Operation ......................................................................................................................................................85

9.1 Safety Instructions for Operation........................................................................................................ 85

9.2 Checking for Correct Installation and Function ................................................................................. 85

10 Maintenance..................................................................................................................................................86

10.1 Safety .................................................................................................................................................... 86

10.2 Replacing the Silencer.......................................................................................................................... 86

10.3 Replacing the Press-In Screens............................................................................................................. 86

10.4 Cleaning the Compact Terminal.......................................................................................................... 86

11 Spare and wearing parts, accessories .........................................................................................................87

11.1 Spare and Wearing Parts ..................................................................................................................... 87

11.2 Accessories ............................................................................................................................................ 87