schmersal AZ201ST2-T-1P2P-DU User manual

Other schmersal Switch manuals

schmersal

schmersal TQ 700 S User manual

schmersal

schmersal EX-ZQ 900 User manual

schmersal

schmersal AZ 16zi Programming manual

schmersal

schmersal AZ 415-33ZPK User manual

schmersal

schmersal EX-T 335 User manual

schmersal

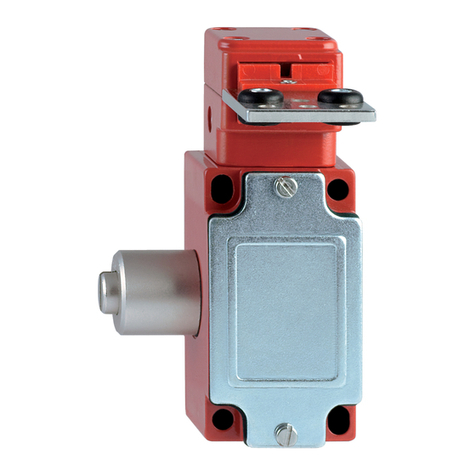

schmersal AZM300Z-I2-ST-1P2P-DU Operation and maintenance manual

schmersal

schmersal SHGV User manual

schmersal

schmersal AZM300Z-ST-SD2P-T-DU User manual

schmersal

schmersal AZM201Z-CC-T-1P2PW-2719-1 Service manual

schmersal

schmersal AZ 200 AS User manual

schmersal

schmersal BN 20 User manual

schmersal

schmersal AZM201Z-ST-T-1P2PW-2965-1-DU Operation and maintenance manual

schmersal

schmersal G50 User manual

schmersal

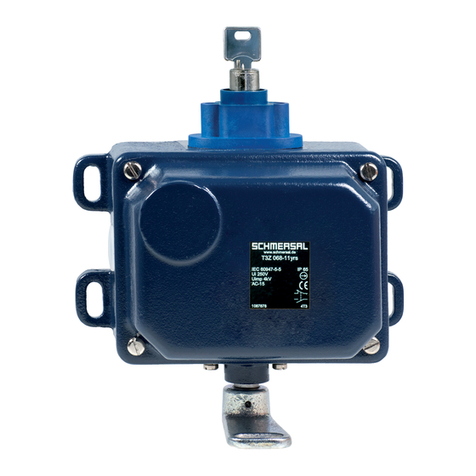

schmersal EX-T3Z 068 User manual

schmersal

schmersal EX-SHGV User manual

schmersal

schmersal AZM201B-SK-T-1P2PW-A Operation and maintenance manual

schmersal

schmersal TQ 700 S User manual

schmersal

schmersal MZM 120 User manual

schmersal

schmersal Z/T 235 AS User manual

schmersal

schmersal TQ200 User manual

Popular Switch manuals by other brands

SMC Networks

SMC Networks SMC6224M Technical specifications

Aeotec

Aeotec ZWA003-S operating manual

TRENDnet

TRENDnet TK-209i Quick installation guide

Planet

Planet FGSW-2022VHP user manual

Avocent

Avocent AutoView 2000 AV2000BC AV2000BC Installer/user guide

Moxa Technologies

Moxa Technologies PT-7728 Series user manual

Intos Electronic

Intos Electronic inLine 35392I operating instructions

Cisco

Cisco Catalyst 3560-X-24T Technical specifications

Asante

Asante IntraCore IC3648 Specifications

Siemens

Siemens SIRIUS 3SE7310-1AE Series Original operating instructions

Edge-Core

Edge-Core DCS520 quick start guide

RGBLE

RGBLE S00203 user manual