2

Operating instructions

Safety switch TZG

EN

1.6 Warning about misuse

In case of improper use or manipulation of the safety

switchgear, personal hazards or damages to machinery

or plant components cannot be excluded. The relevant

requirements of the standard ISO 14119 must be observed.

1.7 Exclusion of liability

We shall accept no liability for damages and malfunctions resulting from

defective mounting or failure to comply with this operating instructions

manual. The manufacturer shall accept no liability for damages

resulting from the use of unauthorised spare parts or accessories.

For safety reasons, invasive work on the device as well as arbitrary

repairs, conversions and modifications to the device are strictly

forbidden; the manufacturer shall accept no liability for damages

resulting from such invasive work, arbitrary repairs, conversions and/or

modifications to the device.

2. Product description

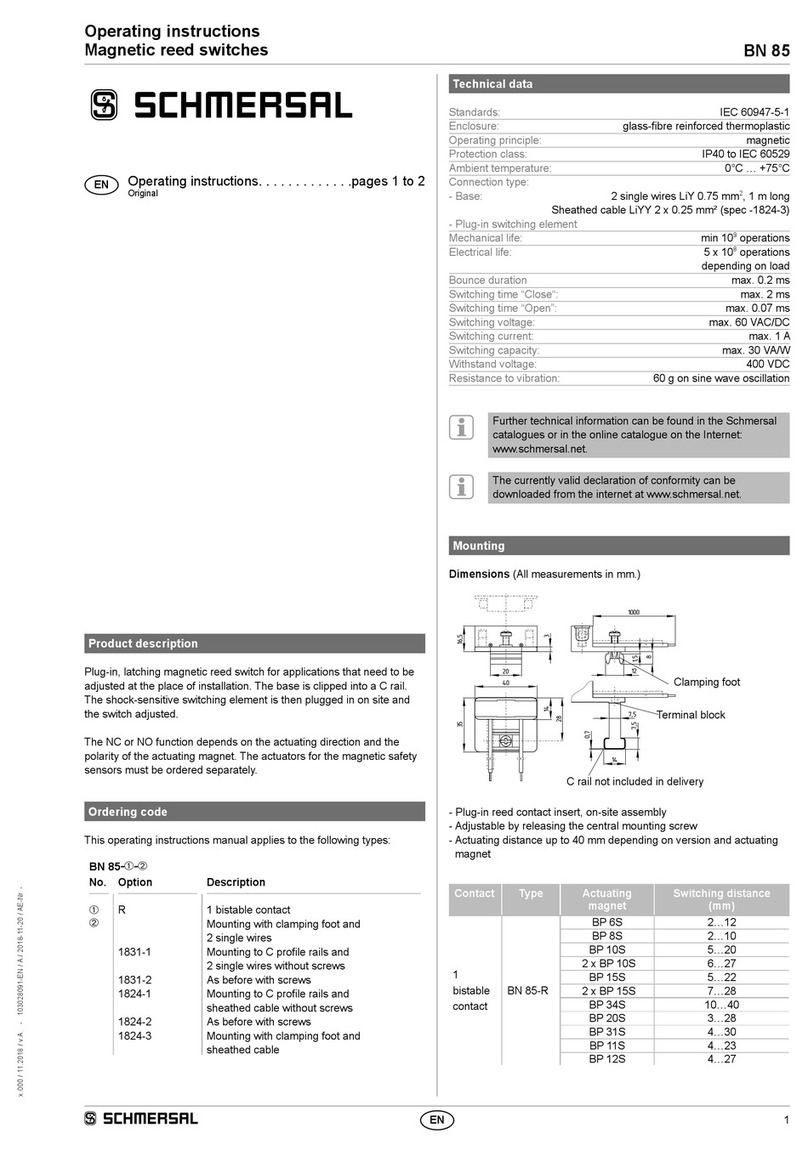

2.1 Ordering code

This operating instructions manual applies to the following types:

TZG

➀➁

/

➂

No. Option Description

➀

Slow action

P Snap action only 1 NC /1 NO contact

➁

01 Head positioned to the front

02 Head positioned to the left

03 Head positioned to the right

04 Head positioned to the rear

➂

103 1 NC contact / 1 NO contact

110 2 NC contacts

1103 2 NC contact / 1 NO contact

3330 3 NC

Not all component variants, which are possible according to this order

code, are available.

Only if the information described in this operating instructions

manual are realised correctly, the safety function and

therefore the compliance with the Machinery Directive is

maintained.

2.2 Special versions

For special versions, which are not listed in the order code below 2.1,

these specifications apply accordingly, provided that they correspond to

the standard version.

2.3 Purpose

The safety switch has been designed to prevent, in conjunction with the

control part of a machine, movable safety guards from being opened

before hazardous conditions have been eliminated. They are also

suitable for fitting on profile sections and existing equipment.

Safety switches can only be used for applications, in which

the hazardous situation is terminated without delay (e.g. run-

on movements) when the safety guard is opened.

When the safety guard is opened, the NC contacts are positively

opened and the NO contacts are closed.

The user must evaluate and design the safety chain in accordance with

the relevant standards and on the required safety level.

2.4 Technical data

Standards: IEC 60947-5-1; EN ISO 13849-1;

ISO 14119; BG-GS-ET-15

Enclosure: glass-fibre reinforced thermoplastic, self-extinguishing

Actuator: steel

Contact material: Silver

Protection class: IP67

Contact type: change-over with double break Zb,

or 2 NC contacts, or 3 NC contacts,

galvanically separated contact bridges

Switching system: AIEC 60947-5-1; slow action,

NC contact with positive break

Connection: screw terminals

Cable type: solid wire

Cable section: 0,5 … 2,5 mm²

Cable type: stranded wire

Cable section 0,5 … 1,5 mm²,

with conductor ferrules,

Cable entry: M20 × 1,5

Actuating speed: 0.2 m/s

Actuating frequency: max. 1200 operations/h

Mechanical life: > 1 million operations

Ambient temperature: −25 °C … +70 °C

Utilisation category: AC-15, DC-13

Ie/Ue:8 A / 230 VAC; 5 A / 24 VDC

only TZGP: 6 A / 230 VAC; 4 A / 24 VDC

Ui:400 V

only TZGP 250V

Uimp:2.5 kV

Ithe:10 A

Us:24 VAC/DC 110/230 VAC

Max. fuse rating: 10 A gG D-fuse

2.5 Safety classification

Standards: EN ISO 13849-1

B10d (NC contact): 2.000.000

B10d (NO contact) at 10% ohmic contact load: 1.000.000

Service life: 20 years

TF

D

10Dopop

op

n

3. Mounting

3.1 General mounting instructions

3/2 mounting holes are provided for fixing the switch. The safety

switch must not be used as end stop. Any mounting position. The

mounting position however must be chosen so that the components

are protected against soiling and damage. In case of painting activities,

the components must be covered. The supplied fixing material must

be used. If another actuating direction is desired, the four screws of

the actuating head must be loosened. Turn the actuating head in the

desired direction and retighten the screws (tightening torque 0.5 Nm).

The default screws installed in the actuating head can be replaced with

the supplied tamperproof screws.

Mounting of the actuators: See mounting instructions actuators.

Please observe the remarks of the standards EN ISO 12100,

EN 953 and ISO 14119.

The 3-pole variants can only be connected to 2 screw points.

For stability reasons, at least the hatched area shown on the

image must be provided as full contact surface.