Operating table OPX mobilis –

E

DITION

01-05-GB ID.-Nr.: 02007844

7

Safety instructions

The operating table OPX mobilis has been constructed

according to the latest state of engineering and according

to the acknowledged rules of safety engineering.

Nevertheless, its use may inflict danger to life or physical

safety of the user or of third parties, or impairment to the

operating table or to other material assets.

Do not use the operating table unless in perfect condition

and only for its intended use, with regard to safety and

possible dangers, and observing the operating manual!

Any malfunction which may affect the safety has to be

eliminated immediately!

Electrically conductive double castors, electrically

conductive pads and a potential equalization socket are

standard features of the operating table OPX mobilis. It

may be used inside rooms where the electrical installation

conforms to German VDE (i. e. the Association of

German Electrical Engineers) 0100-710 standard or to

an equivalent national standard. If the operating table

OPX mobilis is equipped with non-electrically conductive

(coloured) pads, it must not be used in the presence of

flammable anaesthetic mixtures.

Always keep this operating manual at hand at the site of

use of the operating table!

Additionally to the operating manual, observe the

general rules implied by the law and otherwise obligatory

for accident prevention and environmental protection!

Do not carry out any modifications, extensions or

reconstructions of the operating table unless approved by

the manufacturer.

Spare parts have to meet the requirements stipulated by

the manufacturer. This is always guaranteed when using

original spare parts.

Observe the intervals prescribed or stated in this

operating manual for periodical check-ups!

Take care that running and process materials as well as

parts replaced are disposed of safely and with minimum

environmental impact!

Intended use

According to German VDE 0100-710 standard, the

operating table OPX mobilis may be used inside rooms of

the application groups 0, 1 or 2. It is exclusively designed

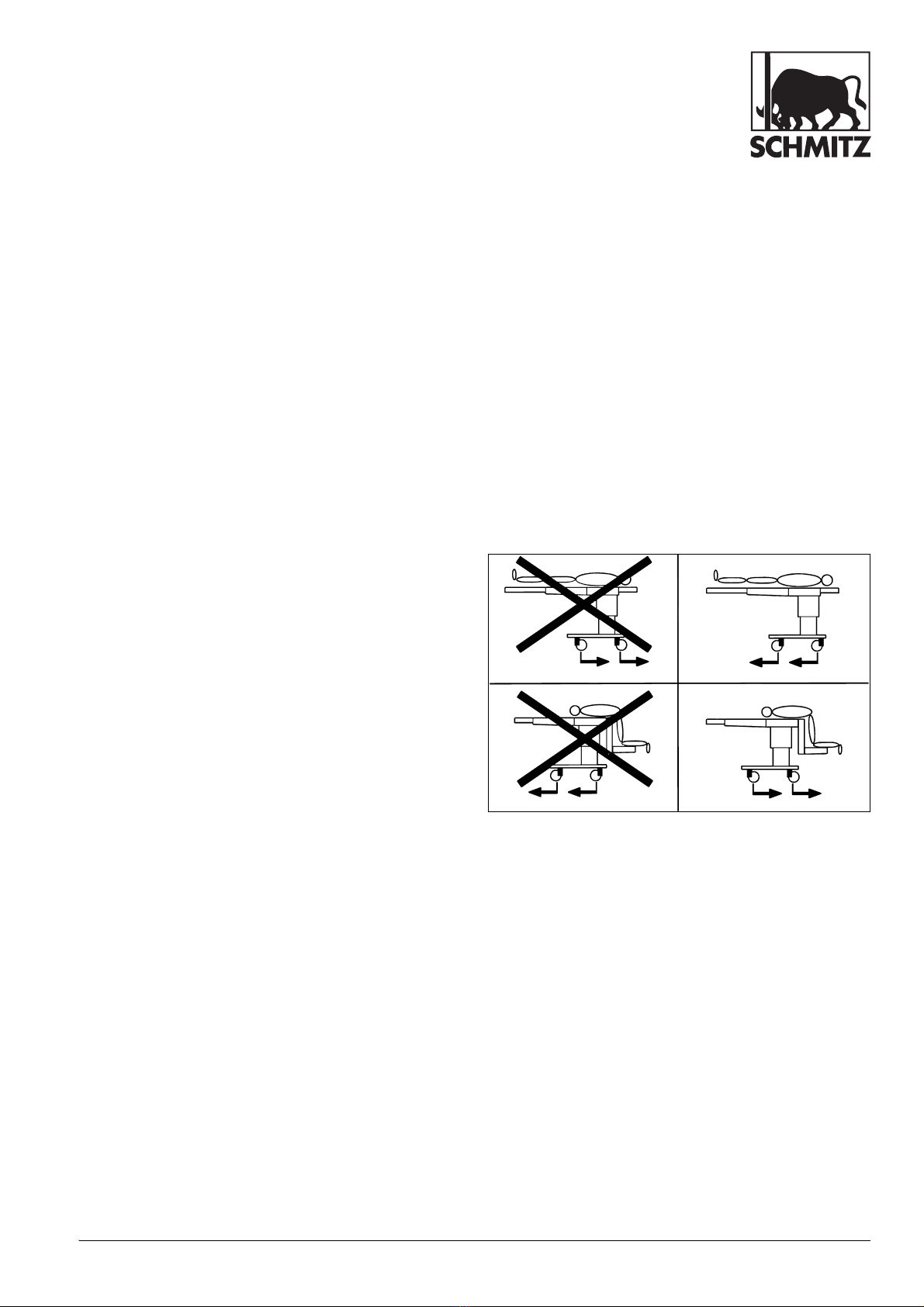

for purposes of human medicine. The operating table

serves to position patients during an examination or

during surgical interventions. The nursing staff has to take

care to position the patients in such a way as to prevent

any danger to their respiration, to their nervous system or

to their circulation. This is especially important when

patients are under anaesthetics. Any use apart or beyond

these purposes is not intended. The manufacturer is not

liable for any damage resulting of such non-intended

use, which would be entirely at the user’s risk.

The operating table may only be handled by persons who

have been briefed in its professional handling and who

have familiarized themselves with the product by means

of this operating manual.

Intended use also means following the operating manual

and observing the conditions for inspection and

maintenance.