SCHUNK ROTA-S flex 550 User instructions

Other SCHUNK Industrial Equipment manuals

SCHUNK

SCHUNK KSC 125 User guide

SCHUNK

SCHUNK PHL Series User instructions

SCHUNK

SCHUNK PGL-plus-P User instructions

SCHUNK

SCHUNK MPG-plus 16 User instructions

SCHUNK

SCHUNK ROTA TB2 470-185 User instructions

SCHUNK

SCHUNK ROTA-M flex 2+2 Series User instructions

SCHUNK

SCHUNK ROTA TP Series User instructions

SCHUNK

SCHUNK OSE 40 User instructions

SCHUNK

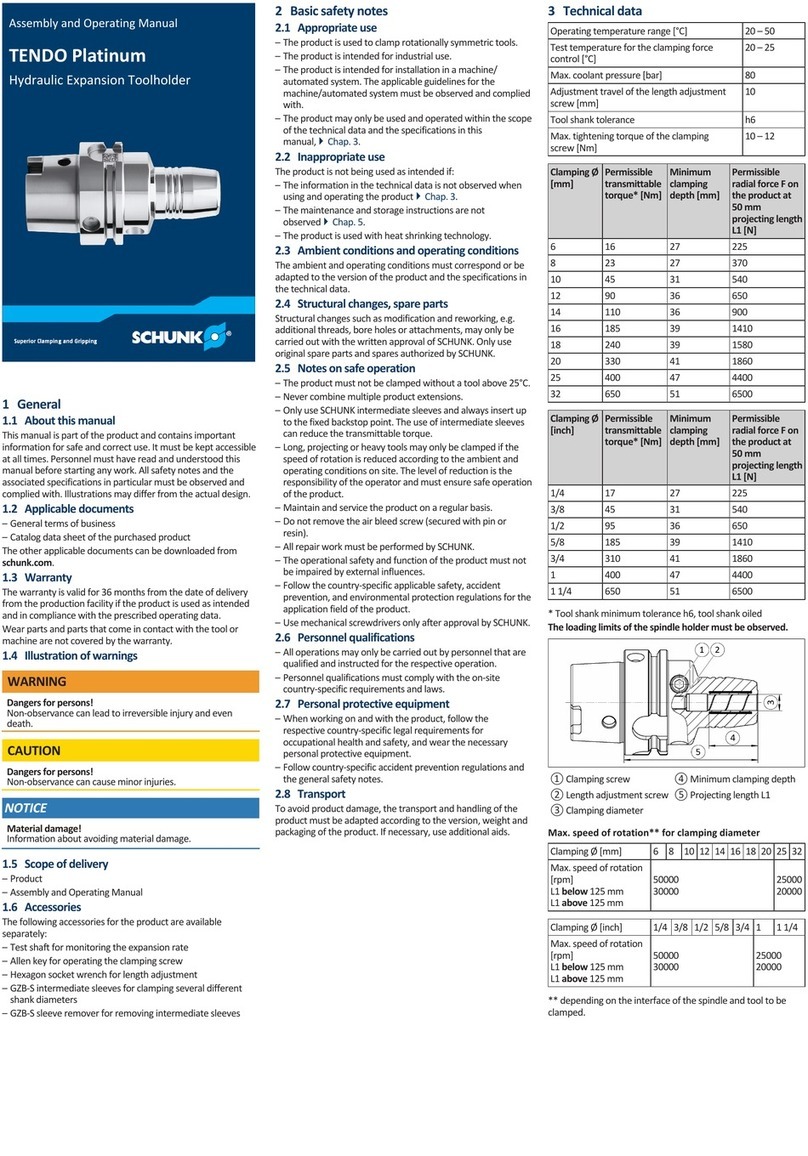

SCHUNK TENDO Platinum User instructions

SCHUNK

SCHUNK ROTA THW3 Operation manual

SCHUNK

SCHUNK SRU-plus Series User instructions

SCHUNK

SCHUNK PLG 20 Operation manual

SCHUNK

SCHUNK ROTA TP User instructions

SCHUNK

SCHUNK SMPL User instructions

SCHUNK

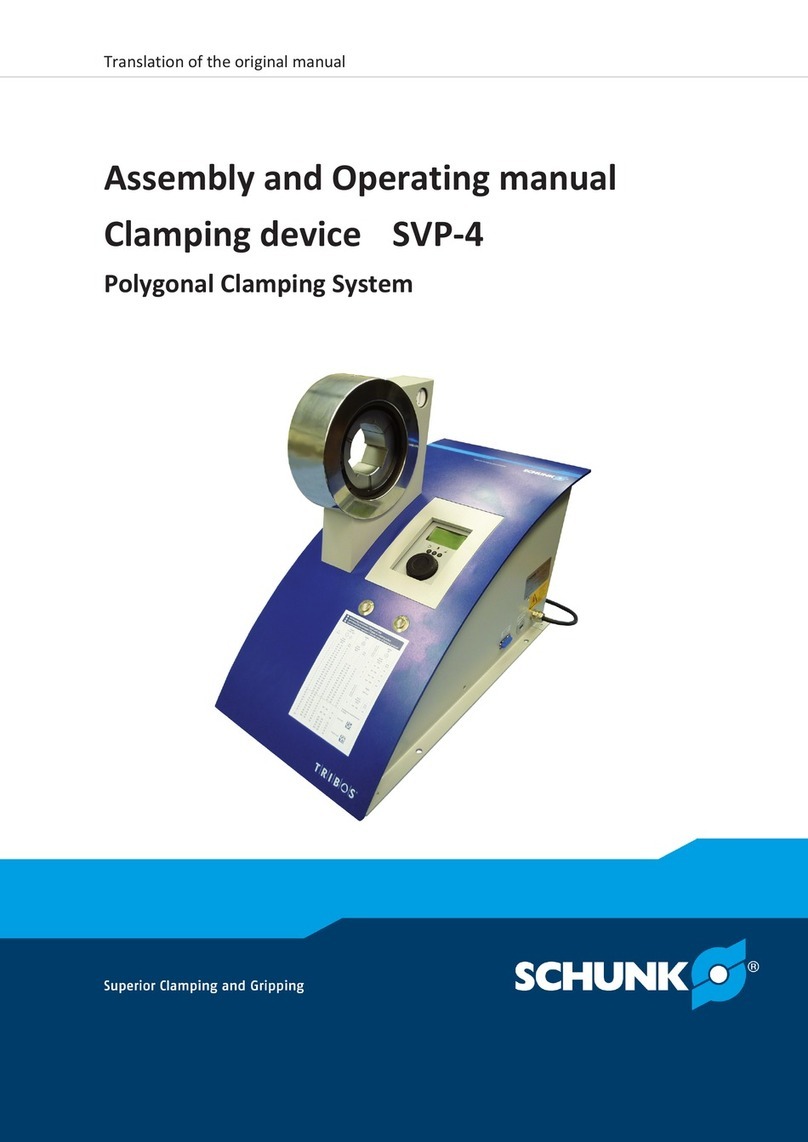

SCHUNK SVP-4 User instructions

SCHUNK

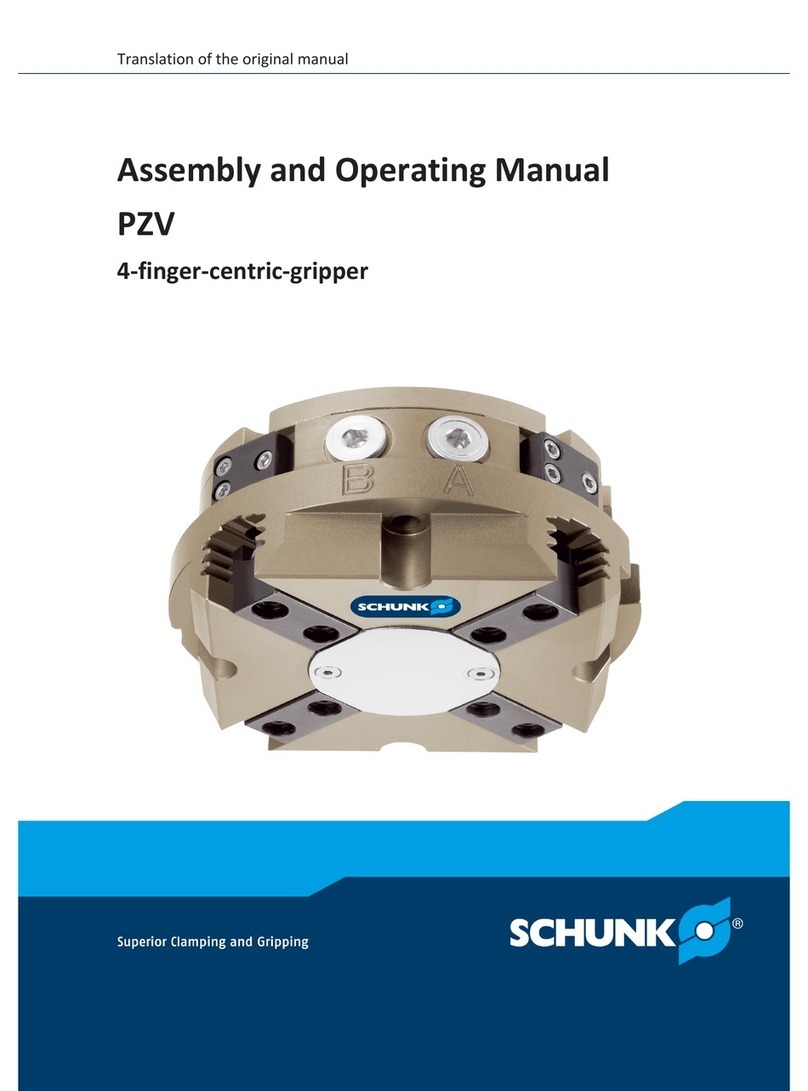

SCHUNK PZV User instructions

SCHUNK

SCHUNK CDB User instructions

SCHUNK

SCHUNK SWS Series User instructions

SCHUNK

SCHUNK NSR maxi 220 User instructions

SCHUNK

SCHUNK EGS Series User instructions