Table of contents

Table of contents

1 General.................................................................................................................... 5

1.1 About these instructions ...................................................................................... 5

1.2 Depiction of Warnings.......................................................................................... 5

1.3 Associated Documentation .................................................................................. 5

1.4 Warranty .............................................................................................................. 6

2 Fundamental Safety Instructions.............................................................................. 7

2.1 Intended Use ........................................................................................................ 7

2.2 Non-Intended Use ................................................................................................ 7

2.3 Danger Zone ......................................................................................................... 7

2.4 Environmental and Operating Conditions ............................................................ 8

2.5 Personnel Qualifications....................................................................................... 8

2.6 Personal Protective Equipment............................................................................ 9

2.7 Technical Condition .............................................................................................. 9

2.8 Responsibility of the Operating Company..........................................................10

2.9 Country-Specific Regulations for the Operating Company................................. 10

3 Product Description ................................................................................................11

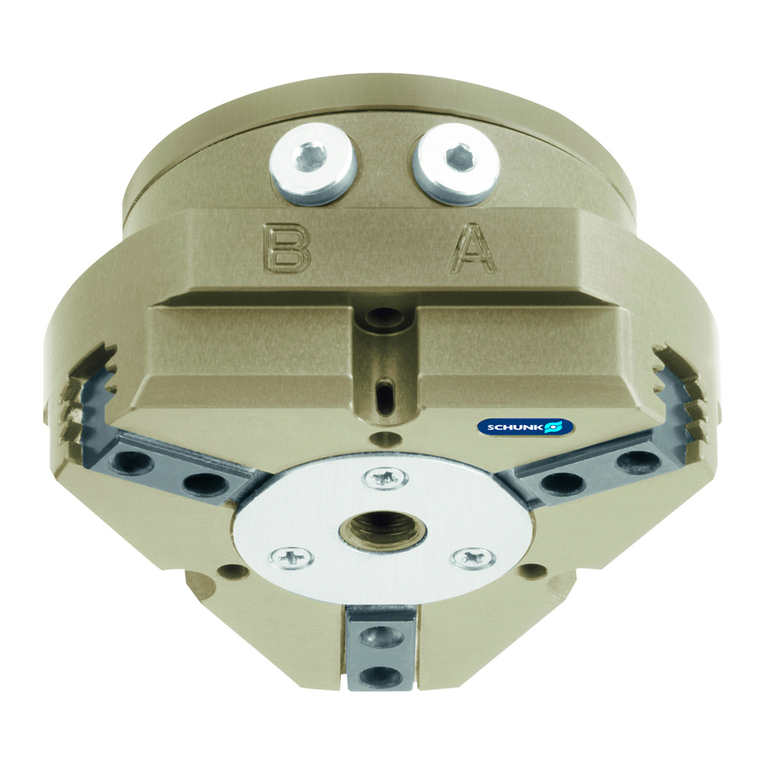

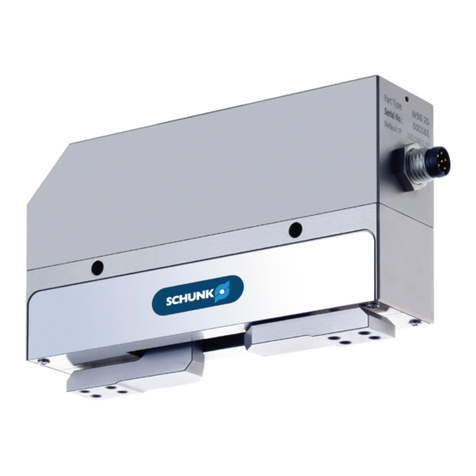

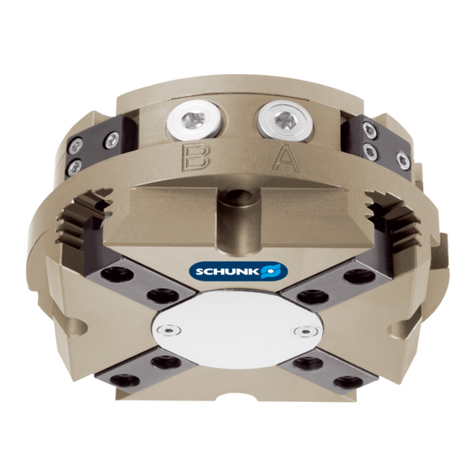

3.1 Description of the Steel-Plate Clamping System with Suction Cups and FlexMat...

11

3.2 Variants and Type Keys / Technical Data............................................................ 14

3.3 Properties of the Clamping System .................................................................... 17

3.4 Calculating the Clamping Force .......................................................................... 19

4 Transport and Storage ............................................................................................20

4.1 Checking the Delivery......................................................................................... 20

4.2 Storage ............................................................................................................... 20

5 Installation .............................................................................................................21

5.1 Installation Instructions...................................................................................... 21

6 Start of Operations .................................................................................................22

6.1 Personnel Qualification ...................................................................................... 22

6.2 Before Initial Start of Operations ....................................................................... 22

7 Operation ...............................................................................................................24

7.1 Preparations ....................................................................................................... 24

7.2 Processing........................................................................................................... 25

8 Troubleshooting .....................................................................................................27

8.1 Safety.................................................................................................................. 27

8.2 Faults, Causes, Solutions when Working with Steel-Plate and Suction Cups .....27

8.3 Faults, Causes, Solutions when Working with Steel-Plate and FlexMat............. 33

301 | SMPL with ISST, SFM and ISBL | Assembly- and Operating Manual | en-US |

1512656