8VarioProtect XXL-W-2 TC | Version 1.01 | EN

Product characteristic and setting options

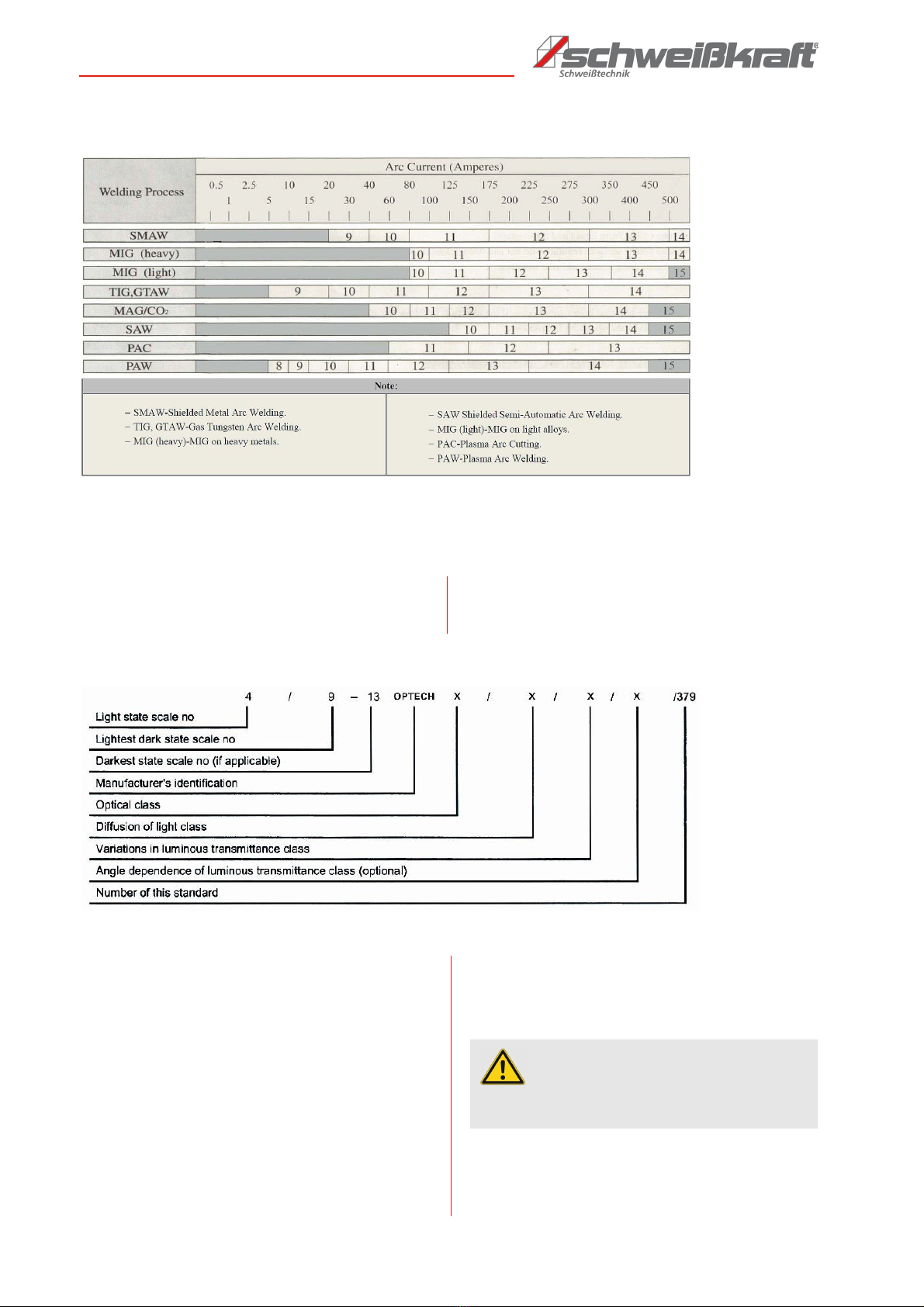

7.4 Setting the shade control

The shade ranges (from DIN4 to DIN8, or from DIN9 to

DIN13) are selected with the shade knob on the inside of

the helmet (Fig. 4).

Thanks the welding filters, the eyes and face of the wel-

der are completely protected against UV and IR radiation

during the welding work, even if the cassette does not

darken. The UV/IR protection is always up to DIN 16, so

the user is always protected against UV/IR radiation du-

ring welding.

Before welding, set the shading level according to the

welding method and welding current in accordance with

the colour table (Fig. 8).

If the darkening is too strong or too slow, adjust the knob

slightly until the weld spot can be seen.

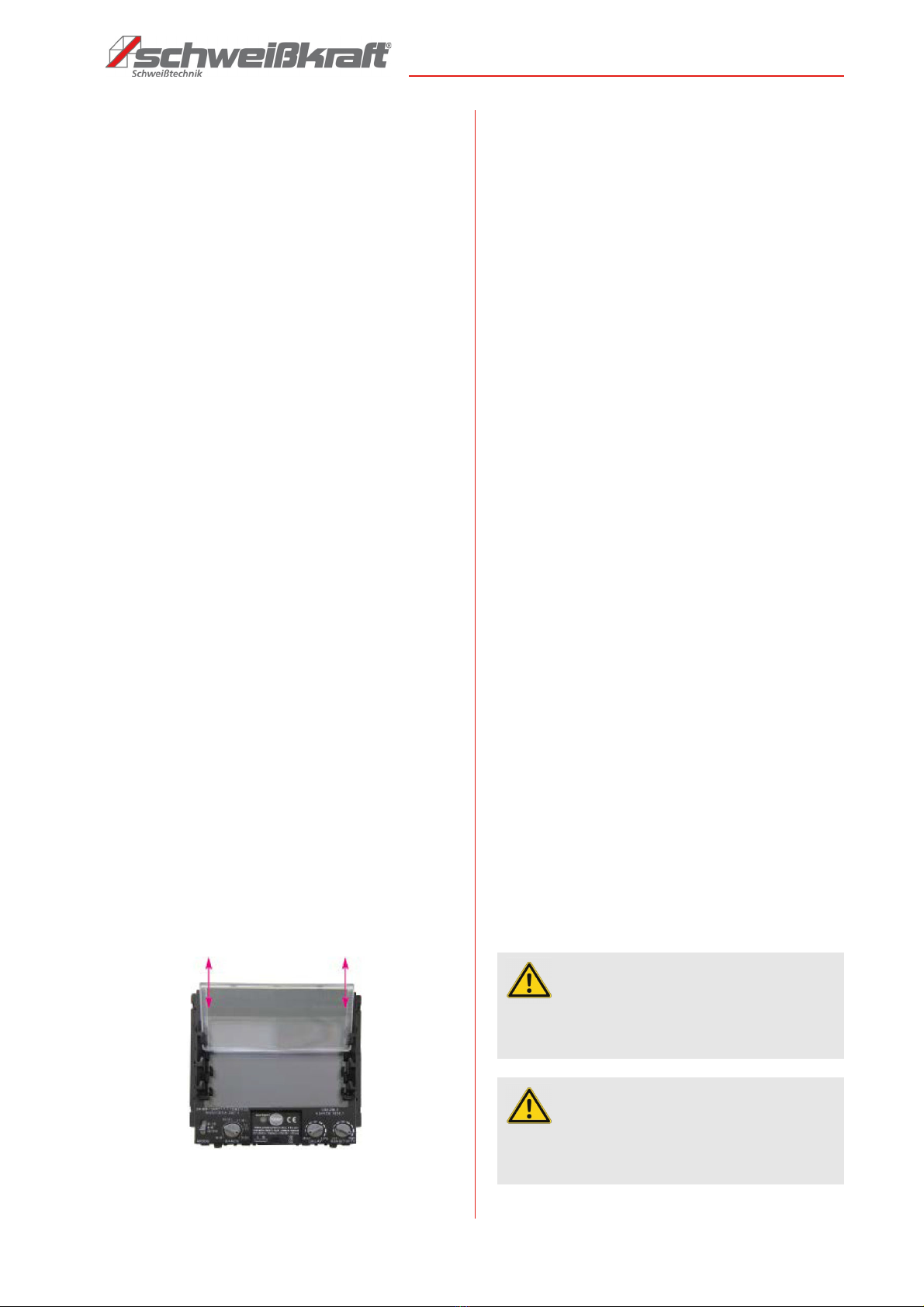

7.5 Power supply, test button

The power supply for the welding helmet is provided by a

battery.

By pressing the Test button, the charge level of the lit-

hium battery and the function of the filter can be chec-

ked.

Fig. 5: Battery test

During normal operation of the filter, after pressing the

Test button, the battery indicator lights up red and the fil-

ter darkens.

If the battery indicator does not lightening or light is very

weak, the battery must be replaced (battery type

CR2450, lithium battery).

If the battery indicator lights up and the filter does not

darken, the filter is defective and must be replaced.

7.6 Headband adjustment options

Fig. 6: Headband adjustment

1. Upper headband W (Fig. 6) - Adjustment in the direc-

tion of the arrow further or narrower to adjust the hel-

met to a suitable position.

2. Side bands Z - Adjustment option symmetrically

further or narrower in the direction of the arrow on

both sides to adjust the distance of the user's eyes to

the filter lens. To adjust, loosen the knobs on both si-

des of the helmet, move the helmet symmetrically to

the appropriate position and retighten the knobs.

3. Rear headband Y - Adjustment with knob further or

narrower to adjust the fit of the helmet looser or fir-

mer..

4. Tilt angle X - 4 adjustment options to adjust the height

of the user's eyes to the filter lens and the angle of the

helmet to the user's face. To adjust, loosen the knobs

on the outside of the helmet, move the helmet to the

appropriate position and retighten the knobs.

Due to the adjustment of the headband results in a maxi-

mum comfort.

This model is equipped with a folding mechanism (up and

down). When the welder turns the helmet towards the top of

the head, the headband mechanism makes the helmet's cen-

tre of gravity a little lower and coincides with the centre of

gravity of the welder's head.

The design of the welding helmet provides for less fatigue on

the head and neck of the welder, and thus for a more comfor-

table feeling while working.

If the headgear has been unevenly adjusted, and the di-

stance from the eyes to the filter lens is uneven, reset the

headgear to reduce the distance to the filter.

ATTENTION!

Before starting welding, it is important that the opera-

ting mode switch is set to a protection level for wel-

ding again.

ATTENTION!

If the welding helmet is used for a long time with the

wrong shading level, the eyes may be injured!