These hotplates are general purpose hotplates that are robustly con-

structed and designed for continual usage. All Models are controlled

by an energy regulator which varies the power input to the elements

enabling ner control at lower surface temperature. There is no sur-

face temperature indication.

PRODUCT DESCRIPTION

THESE INSTRUCTIONS MUST BE FOLLOWED FOR US TO

GUARANTEE OUR FULL SUPPORT OF YOUR CLAIM FOR

PROTECTING AGAINST LOSS FROM CONCEALED DAMAGE.

THE FORM FOR FILING SUCH A CLAIM WILL BE PROVIDED

BY THE CARRIER.

UNPACKING

Unpack the product and check for any damage incurred during

transit. This should be reported to the responsible carrier, railway or

postal authority, and a request for a damage report should be made.

1. Ensure that the unit is placed on a sturdy bench.

2. Install the unit away from combustible material and preferably

at least 300mm away from the wall or adjacent surfaces.

3. Check that the mains voltage complies with the rated

220-240VAC 50Hz-15 amp supply voltage and plug into power

socket.

4. To energize the heating elements turn the energy regulator

knob marked 0 to 6 to the desired setting.

5. The hotplate element will cycle on and off at the setting

selected.

6. To have the heating elements permanently energized, the knob

should be turned to position 6.

7. The hotplate top is covered with a special heat resistant

coating which may smoke initially as the unit is burned in.

This is normal.

GENERAL INSTALLATION AND OPERATION INFORMATION

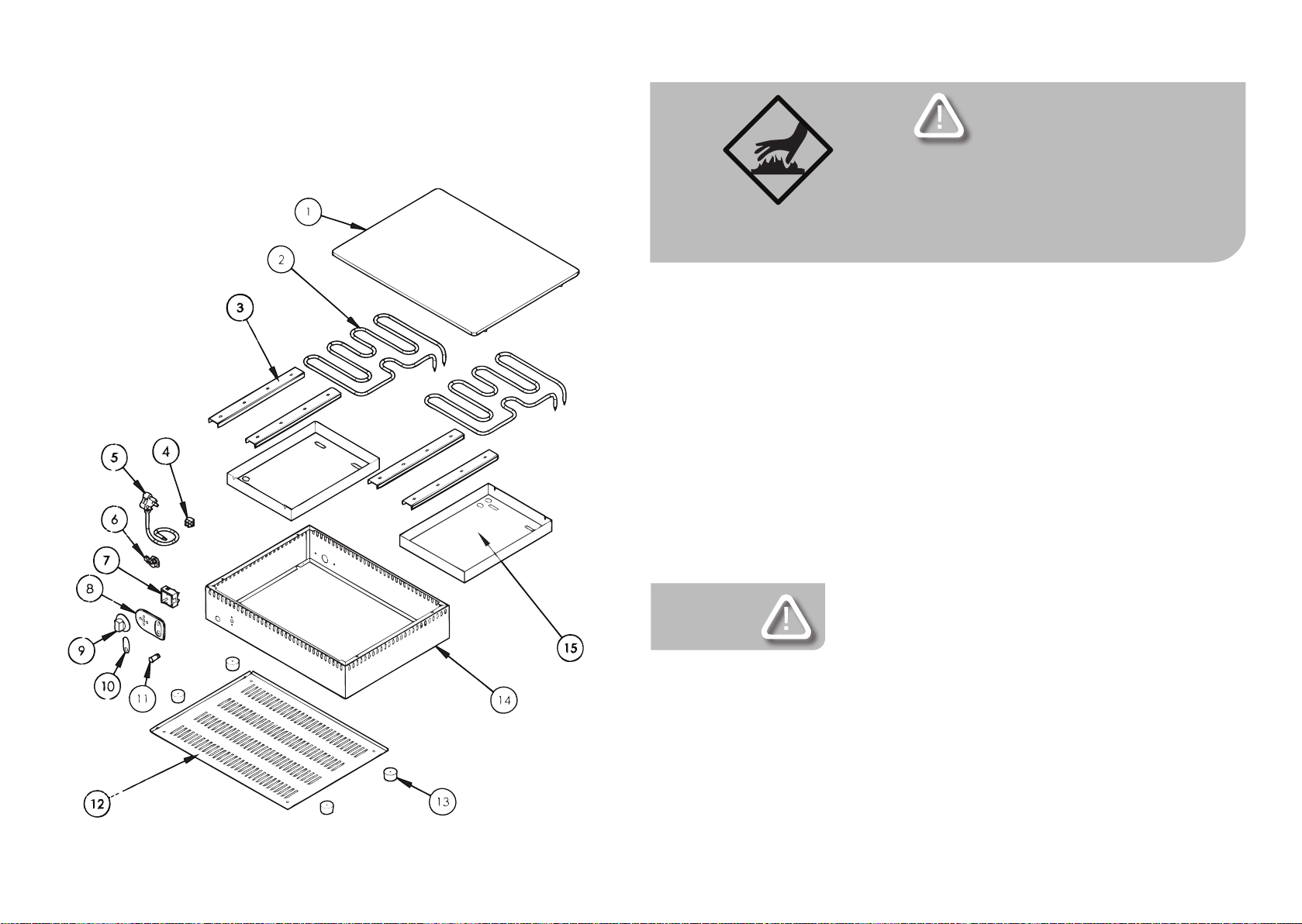

Part

1 502 TOP PLATE

2 ELEMENT 1500W 230V

3 ELEMENT CLAMP

4 TERMINAL BLOCK

5 POWER CORD

6 CABLE GRIP

7 ENERGY REGULATOR

8 CONTROL PANEL

9 KNOB

10 CONTROL PANEL INSERT

11 PILOT LIGHT

12 BOTTOM COVER

13 LARGE RUBBER FOOT

14 BODY ASSEMBLY

15 ELEMENT COVER

Description

MODEL : LABORATORY HOTPLATE

MODEL CODE : 502

1 14