3Hardware Description

3.1 PCap04 Lite Board

3.1.1 Capacitance Measurement

For the purpose of evaluating the capacitance measurement using PCap04, the board is pre-

assembled with ceramic capacitors to emulate capacitive sensors. These capacitors, each 10 pF in

value, are connected to the 6 ports PC0 to PC5. They are connected as single sensors in floating

mode, i.e. each capacitor is connected between 2 ports, and hence there are 3 x 10 pF on-board

capacitors. Please refer to section 3 of the PCap04 data sheet for more information on how to

connect capacitors to the chip. In case using external reference, the capacitor connected between

ports PC0 and PC1 is taken as the reference capacitor.

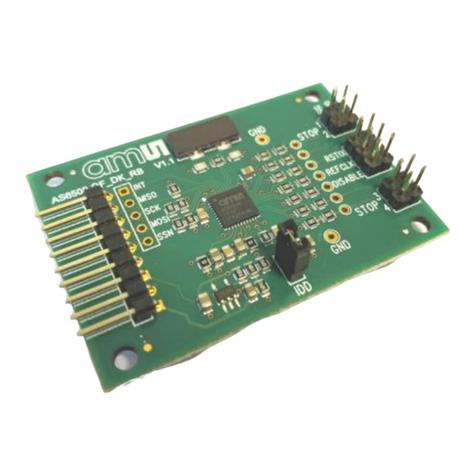

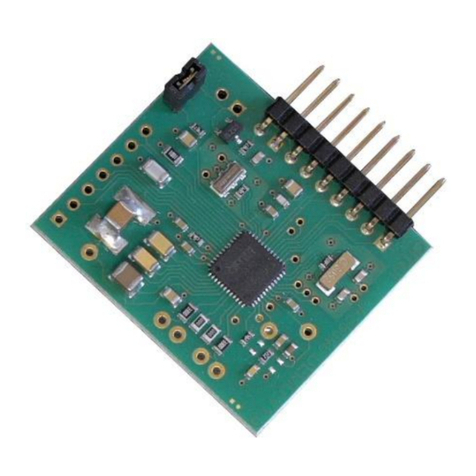

Figure 6: Details of the plug-in board (A=three C0G ceramic capacitors)

In the process of evaluation, when you are comfortable with interpreting the measurement results

from the chip, these fixed capacitors can be replaced with the actual capacitive sensors of your

application.

If you want to connect your capacitive sensors in grounded mode, then GND points are provided at

the two corners of the board, where the sensor ground connections ought to be soldered.

The typical value of the capacitive sensors that can be connected to the evaluation kit lies in the

range of 30 pF to 3.5 nF. The reference capacitor should be in the same order of magnitude as the

sensor. Depending on the value of the sensor, the value of the internal resistor for performing the

measurement has to be selected. For the pre-assembled 10 pF capacitors, an internal discharge

resistor of 90 kΩ works well. See section 3 of the PCap04 data sheet on how to select the value of

the internal discharge resistor.

3.1.2 Temperature Measurement

Temperature measurement or other resistive tasks may also be of interest for the user of this kit.

The evaluation kit offers this possibility through the RDC (resistive-to-digital converter) ports. An on-

chip thermistor coupled with an on-chip temperature-stable reference resistor made of polysilicon

is sufficient for observing the temperature measurement capability of the PCap04 chip.