SciQuip Incu-Shake MAXI V2016.1.1

5

1. Performance Parameters

As one of the unique features, the sophisticated PID controller provides our new units

with great flexible choice of not only constant controlling one fixed temperature and

speed, but also programmed controlling with a series (up to 9 segments, 99 cycles) of

“ramps and soaks”, on just one unit.

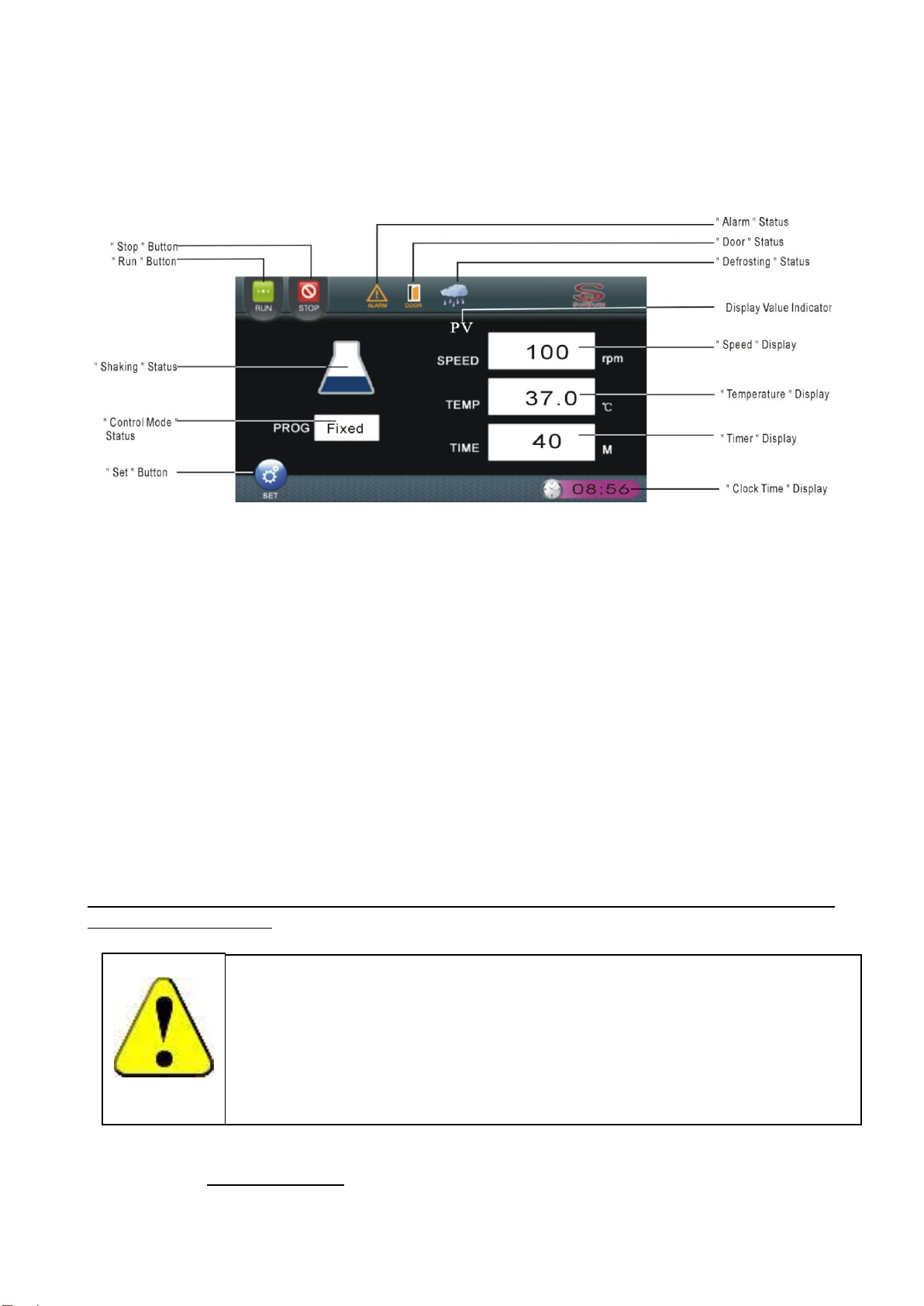

4.3'' LCD 480x272 touch screen panel clearly indicates all parameters in one page

display, which also simplifies all fuzzy settings with just quick finger touches.

Both the interior and exterior are made of robust materials for lifetime operations. The

inner chamber is made of high quality #304 stainless steel sheets. All exposed edges

are de-burred to insure no sharp edges. The exterior is ABS plastic finished with powder

coated polyurethane finish, which is resistant to most chemicals and easily cleaned with

mild household detergents.

The control electronics are protected trough a circuit breaker that may trip at 110% of

loading rate, but will trip within 1 second at 150% of load rating.

Cooling system is controlled by solenoid valves, with independent compressor overload

protection.

Door switch stops the main heater and motor if lid is opened, and switches them back on

once it’s closed in 10 seconds. Otherwise the motor will remain stopped, while the main

heater resumes working.

Heater shuts off when high-temperature limit is exceeded. Shaker stops when excess

vibration is detected.

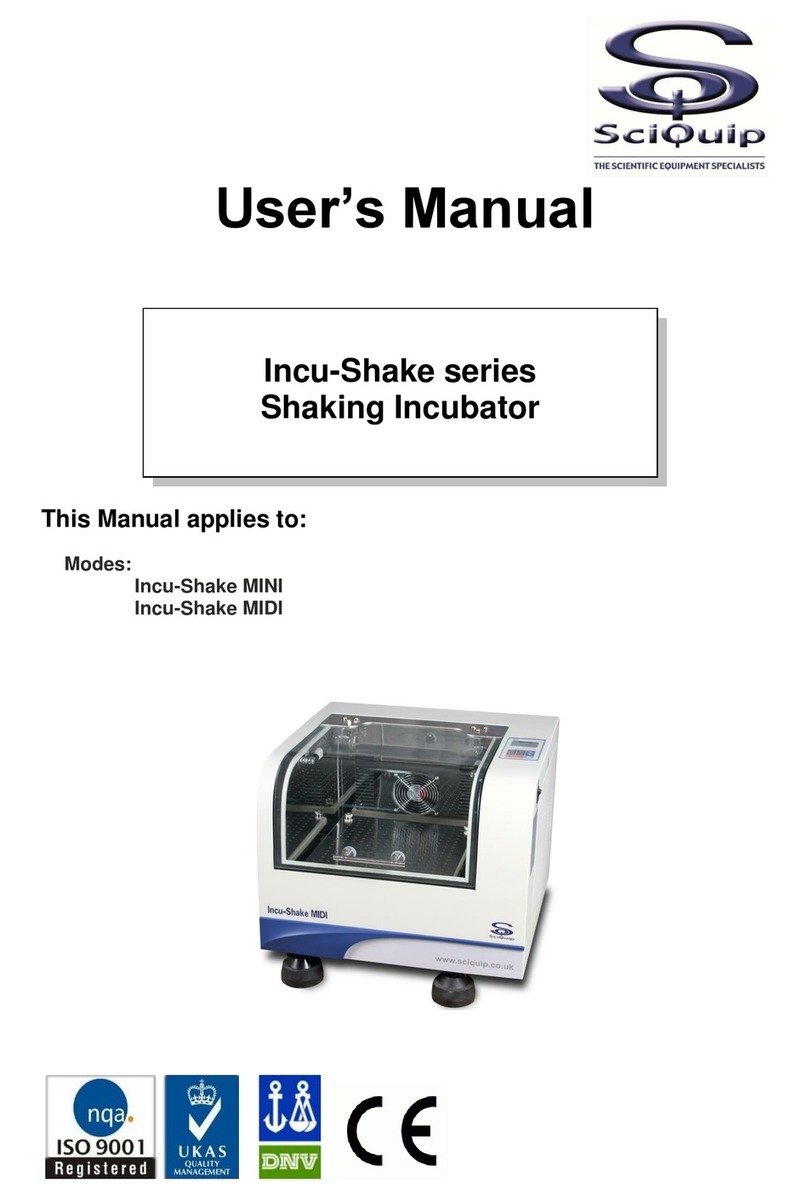

Curved tempered glass lid provides complete visibility of chamber interior, and is

non-scratch and easy to clean.

Electronic timer, from 0 –9999 minutes, automatic stop, audio/ visual alarm.

Audible and visual alarms for motor temperature and set point deviations

Non-volatile memory for set point retention after a power interruption.

“Long-Life” brushless AC motor creates a smooth and quiet shaking motion.