5

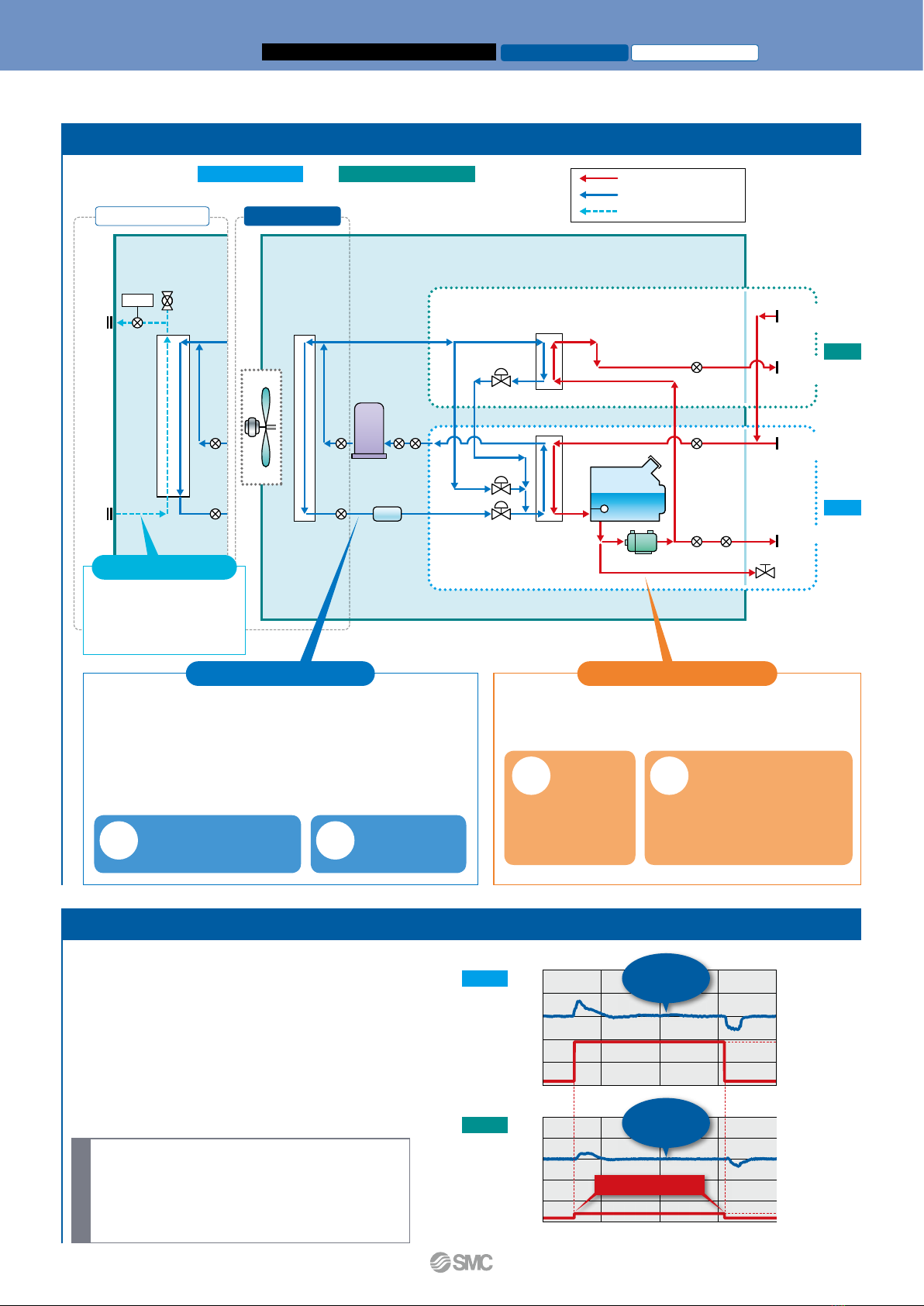

PV

SV

Flashing

Lights up Alarm code

Accumulated

time

Displayed item

PV

Self-diagnosis function and check display

Display of individual alarm codes

Operation is monitored at all times by the integrated sensor.

Should any error occur, the self-diagnosis result is

displayed by the applicable alarm code.

This makes it easier to identify the cause of the alarm.

Can be used before requesting service

Check display

The internal temperature, pressure, and

operating time of the product are displayed.

Changeable alarm set values

Setting item

Circulating fluid discharge pressure rise

Circulating fluid discharge pressure drop

Set range

0.3 to 0.6 MPa

0.05 to 0.6 MPa

Displayed item

Circulating fluid outlet temperature

Circulating fluid return temperature

Compressor gas temperature

Circulating fluid outlet pressure

Compressor gas discharge pressure

Compressor gas return pressure

Accumulated operating time

of the thermo-chiller

Accumulated operating time

of the pump

Accumulated operating time

of the fan∗

1

Accumulated operating time

of the compressor

Accumulated operation time

of the dustproof filter∗

1

Ex. RUN “Accumulated operating

time of the thermo-chiller”

Ex.

AL01 “Low level in tank”

∗1 These are displayed only

for air-cooled refrigeration.

For details, refer to page 17.

Convenient functions (Refer to the Operation Manual for details.)

Anti-freezing operation function

If the circulating fluid approaches its freezing point, for example, on a cold

winter night, the pump operates automatically, and the heat generated by

the pump warms the circulating fluid, preventing freezing.

Key-lock function

Can be set in advance to protect the set values from being

changed by pressing keys by mistake

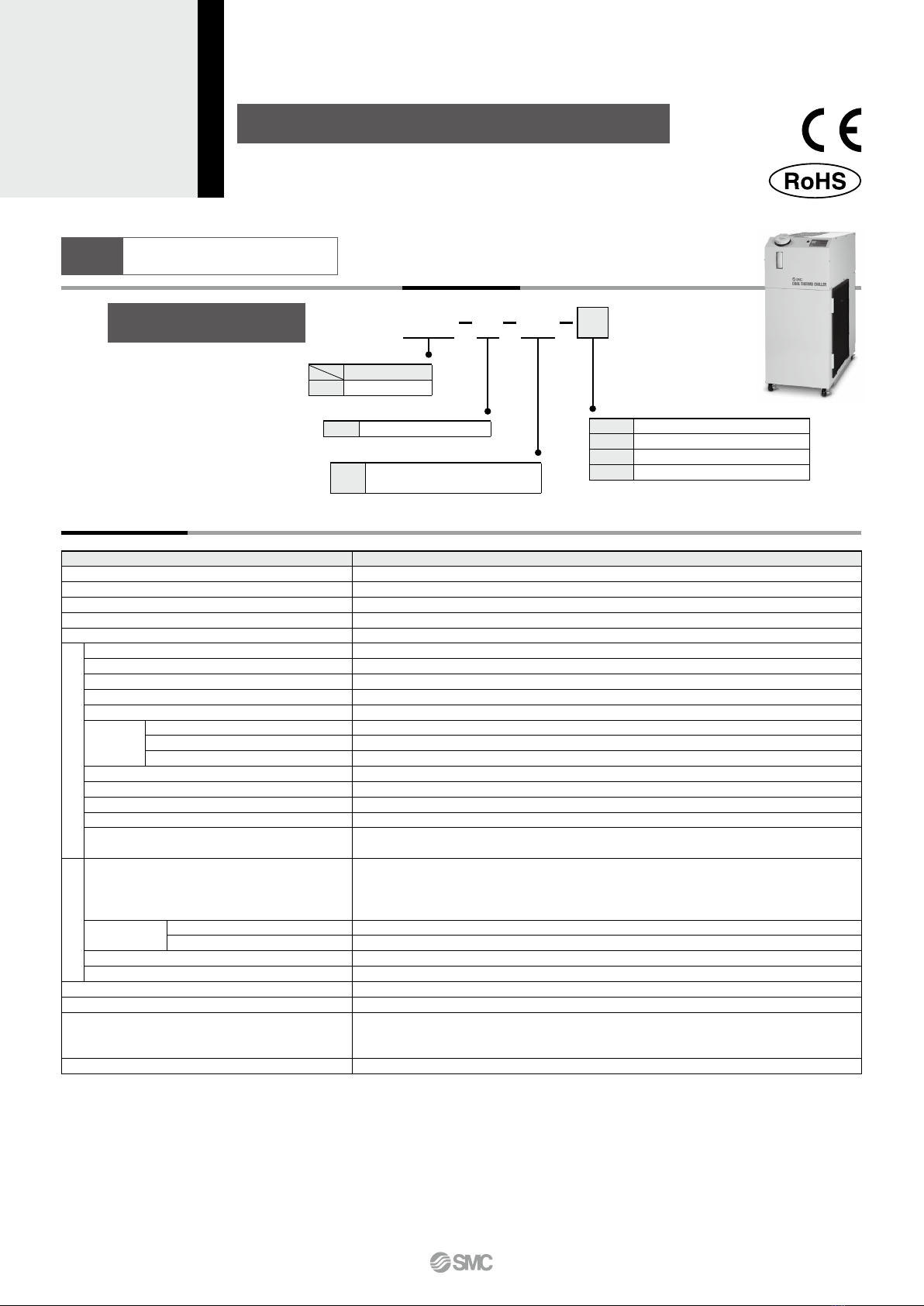

Function to output a signal for completion of preparation

Notifies by communication when the temperature reaches the pre-set

temperature range

PC

HRLE Remote

operation

switch Output 1

Output 2

Output 3

Input 2Input 1 Customer

equipment

HRLE

HRLE

Remote signal I/O through

serial communication

Remote operation is enabled (to start and

stop operation) through serial

communication.

Alarm and operation

status (start, stop, etc.)

signal output

The alarm and status generated in the

product can be output.

Remote operation signal input

One of the contact inputs is used for remote

operation and the other is used to monitor the

flow of a flow switch. This is where their alarm

outputs are taken in.

Flow switch

Low flow switch

flow signal

Output examples

Output 1: Operation status (start, stop, etc.)

Output 2: Alarm status signal

Output 3: Preparation completion status signal

Ex.1 Ex.2 Ex.3

¡

Circulating fluid temperature setting

¡Start and stop

¡Circulating fluid

discharge

temperature

¡

Circulating fluid discharge pressure

¡Run and stop status

¡Alarm information

¡Various setting information

¡Preparation completion status, etc.

Power for flow switches (24 VDC) can be

supplied by the thermo-chiller.

Serial communication (RS485) and contact I/Os (2 inputs and 3 outputs)

are equipped as standard.

This allows for communication with the customer equipment and system

construction, depending on the application.

A 24 VDC output can be also provided and is available for use with flow

switches (SMC’s PF3W, etc.).

Communication functions p. 18

Communication cable

Circulating Fluid Temperature Controller

Thermo-chiller Compact Dual/Basic Type for Lasers

Air-cooled Refrigeration

Water-cooled Refrigeration

HRLE Series