Scotchman CPO-315-RFA-NF User manual

Table of contents

Other Scotchman Saw manuals

Scotchman

Scotchman CPO-315-HFA-CNC User manual

Scotchman

Scotchman GAA-500-90 NF User manual

Scotchman

Scotchman CPO-275 User manual

Scotchman

Scotchman SU-280 User manual

Scotchman

Scotchman SUP-600-NF User manual

Scotchman

Scotchman CPO 350 User manual

Scotchman

Scotchman SU-280-G User manual

Scotchman

Scotchman CPO-350-NF-5HP User manual

Scotchman

Scotchman CPO-315-HFA-NF User manual

Scotchman

Scotchman SUP-600-NF User manual

Popular Saw manuals by other brands

Mafell

Mafell K 65 18M bl Original operating instructions

EINHELL

EINHELL TC-TS 2025 Original operating instructions

Worcraft PROFESSIONAL

Worcraft PROFESSIONAL RS07-115H instruction manual

Klutch

Klutch NT1RS Operator's manual

Worcraft PROFESSIONAL

Worcraft PROFESSIONAL RS07-115 instruction manual

EINHELL

EINHELL BT-SH 90 / 350 Original operating instructions

Reliable Equipment

Reliable Equipment LR-CS-82 Operator's guide

AEG

AEG POWERTOOLS BPS18-254BL Original instructions

Bosch

Bosch GCM 10 PROFESSIONAL Original instructions

Metabo

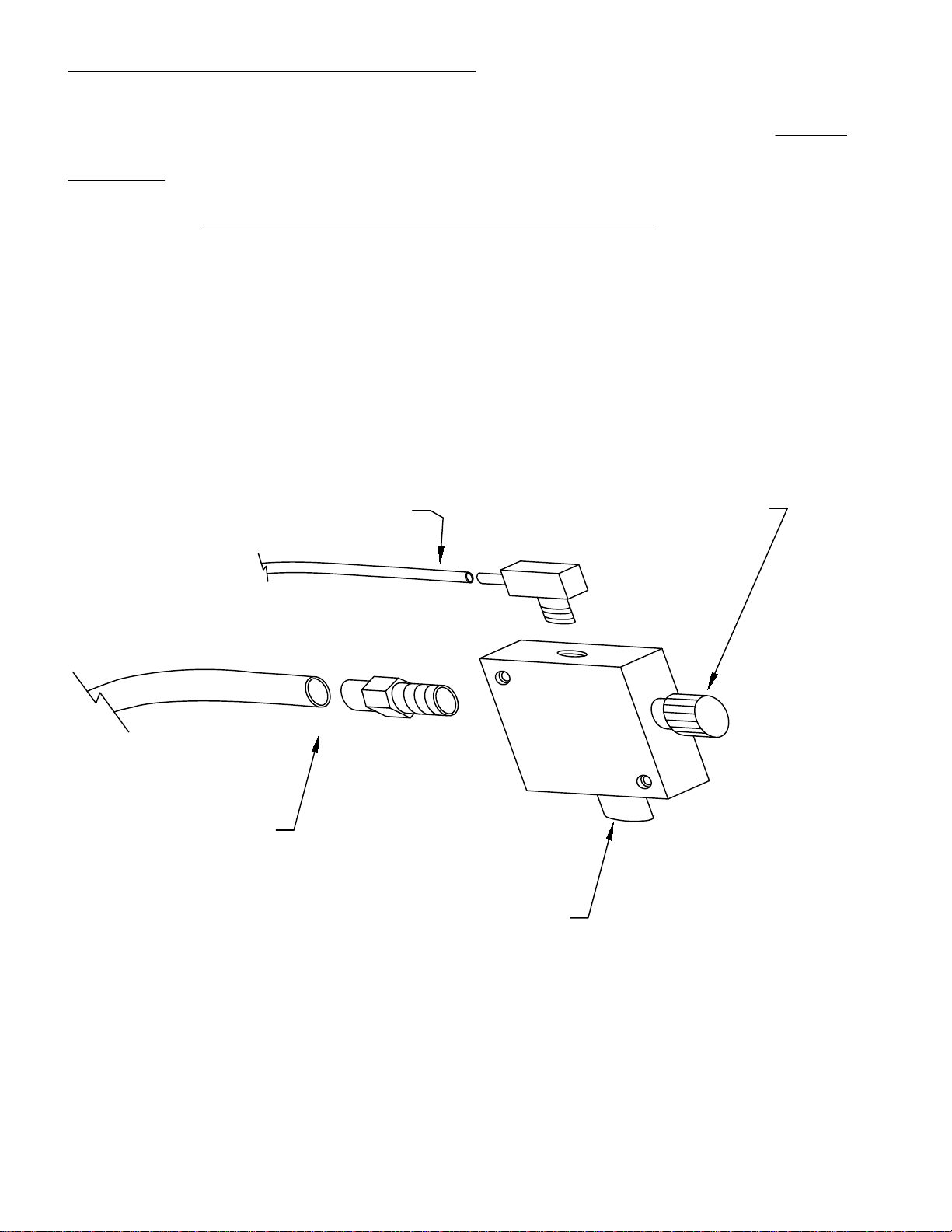

Metabo DKS 10 Set Original instructions

Parkside

Parkside PMTS 210 A1 Operating and safety instructions

Ryobi

Ryobi BS903 Operator's manual