Scotchman CPO-315-HFA-5HP User manual

You have downloaded a manual for our

MODEL CPO-315-HFA-5HP

COLD SAW

Please download our

Cold Sawing Guide too.

Read both the manual and guide

before operating this saw!!

MODEL

CPO-315-HFA-5HP

COLD SAW

PRINTED MAY 2021

www.scotchman.com

SCOTCHMAN IND. - 180 E US HWY 14 - PO BOX 850 - PHILIP, SD 57567 Call: 1-605-859-2542

Page 2

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE #

1.0 INTRODUCTION 4

2.0 SAFETY PRECAUTIONS 4

3.0 WARRANTY 5

4.0 INSTALLATION & SET-UP 6

4.1 Physical Dimensions 6

4.2 Machine Installation 8

4.3 Electrical Requirements 10

4.4 Coolant System 11

5.0 MACHINE START-UP 12

5.1 Control Panel Functions 12

6.0 MACHINE OPERATION 16

6.1 Selecting The Proper Blade and Cutting Speed 16

6.2 Blade Installation 18

6.3 Saw Capacities 21

6.4 Main Vise 22

6.5 Shuttle Vise 25

6.6 Power Down Feed 26

6.7 Material Clamping 28

6.8 Stroke Control Adjustment 28

6.9 Counter Set-up 30

7.0 MACHINE AUTOMATIC OPERATION (SET-UP) 32

8.0 MAINTENANCE 34

8.1 Lubrication 34

8.2 Cutting Oils and Lubricants 35

8.3 Scheduled Maintenance 35

8.4 Gear Replacement (Saw Head) 36

8.5 Spindle Replacement (Main Vise) 38

8.6 Seal Replacement (Main Vise) 39

8.7 Shuttle Vise Maintenance 40

8.8 Coolant Pump Maintenance 42

TABLE OF CONTENTS

SECTION

9.0

9.1

9.2

10.0

10.1

10.2

10.3

10.4

10.5

10.6

11.0

11.1

11.3

11.4

11.5

11.6

DESCRIPTION

OPTIONAL EQUIPMENT

Special Vise Jaws

Optional In Feed Supply Tracks

TROUBLE SHOOTING GUIDE

Electrical Trouble Shooting

Breakage or Excessive Dulling of Blades

Part Length Is Not Consistent

Coolant System

PLC (LED’s)

Pneumatic System

PARTS LISTS

Saw Head

11.2

Shuttle Vise Assembly

Shuttle Assembly

Fine Adjustment Stop Assembly

Power Down Feed Assembly

11.6A

11.6B

11.7

11.8

Air Valve Assembly

Blade Guard Assembly

11.9

11.10

11.11

11.12

Electrical Unit-Line Circuit

Electrical Unit-Secondary Circuit

Base Assembly

11.13

11.14

12.0

12.1

12.2

13.0

14.0

Stroke Control Assembly

11.15

OPTIONAL EQUIPMENT PARTS LISTS

Supply Track Assembly

Cutting Coolants and Lubricants

PAGE #

44

44

44

46

46

46

47

47

48

50

52

52

54

56

58

60

62

64

66

68

70

72

74

76

78

80

82

84

86

86

88

92

93

Page 3

12.3 Vise Pressure Regulator

12.4 Shuttle Vise Pressure Regulator

88

90

15.0

WIRING DIAGRAMS

97

STOCK BLADES

SAFETY VALVE / SOLENOID

Main Vise Assembly

Power Down Feed Valves

Power Down Feed Air Controls

Motor Assembly

Coolant Pump

Hood Assembly

Page 4

The CPO-315 HFA Fully Automatic Cold Saw is designed to cut solids, tubes, flats and other profiles

in grades of material that range from hot and cold rolled steel, annealed tool steels, stainless,

aluminum, brass, copper, synthetics and extrusions.

Cold sawing is a process similar to a milling process. In most cases, this, combined with the variable

speed feature, gives a finished cut that does not require any secondary machining or de-burring.

Since milling spindle speeds are used in cold sawing, there are several things that are required to

achieve quality results. The selection of the proper pitch (number of teeth) on the blade and the

proper spindle speed for the type of material being cut are critical. Proper material clamping and a

good quality coolant are also important.

Cold sawing has several advantages over band saws and abrasive saws. Besides the mill quality cut,

cold saws have the ability to generate faster cutoff times than band saws. There are no sparks and

excessive noises that are associated with abrasive cutoff saws. There is no work hardening of the

workpiece.

Cold saws also offer the advantage of blades that can be re-sharpened until the diameter of the blade

will no longer cut through the material. The vise allows for easy changeover to special clamping jaws

for profiles and extrusions. Having a motor variable speed control enables the user to cut a wide range

of materials.

1.0 INTRODUCTION

2.0 SAFETY PRECAUTIONS

1. The operators of this machine must be qualified and well trained in the operation of this

machine. The operators must be aware of the capacities and the proper use of this machine.

2. This manual is not intended to teach untrained personnel how to operate equipment.

3. NEVER OPERATE THIS MACHINE WITH ANY OF THE PROTECTIVE GUARDS OR

HOODS OPEN OR REMOVED!

4. Wear the appropriate personal protective equipment. Safety glasses are required at all times

when operating or observing this machine in operation.

5. Never place any part of your body into the path of the saw blade, material vises or shuttle

cylinder.

6. Do not wear loose fitting clothing, gloves or jewelry when operating this machine.

7.

8. All electrical connections shall be made by a qualified electrician. This machine must be

grounded in accordance with the National Electric Code.

9. Disconnect the machine from the power source before performing maintenance or changing

blades.

10. Strictly comply with all of the warning labels and decals on the machine. Never remove any

of the labels. Promptly replace worn or damaged labels.

Page 5

10. Practice good housekeeping. Keep the area around the machine clean and dry. Do not obstruct the

operator’s position by placing anything around the machine that would impede the operator’s

access to any of the machine’s functions.

11. When sawing, always support long pieces and make sure that the material is properly clamped.

12. Keep the guards, as well as all other parts of the saw, in good working condition. Replace worn

parts promptly.

13. Do not alter or modify this machine in any way without written permission from the

manufacturer.

14. Set up a program of routine inspections and maintenance for this machine. Make all repairs and

adjustments in accordance with the manufacturer’s recommendations.

3.0 WARRANTY

Scotchman Industries, Inc. will, within 2 years of date of purchase, replace F.O.B. the factory or refund

the purchase price for any goods which are defective in materials or workmanship, provided that the

buyer returns the warranty registration card within thirty (30) days of purchase date and, at the seller’s

option, returns the defective goods, freight and delivery prepaid, to the seller, which shall be the buyer’s

sole and exclusive remedy for defective goods.

Hydraulic and electrical components are subject to their respective manufacturer’s warranties.

This warranty does not apply to machines or components which have been altered, changed or modified

in any way or subjected to abusive or abnormal use, inadequate maintenance or lubrication or subjected

to use beyond the seller’s recommended capacities and specifications.

In no event shall seller be liable for labor costs expended on such goods or consequential damages.

Seller shall not be liable to purchaser or any other person for loss or damage, directly or indirectly

arising from the use of the goods or from any other cause.

No officer, employee or agent of the seller is authorized to make any oral representations or warranty of

fitness or to waive any of the foregoing terms of sale and none shall be binding on the seller.

Any electrical changes made to the standard machine, to comply with local electrical codes, must be paid

by the purchaser.

As we constantly strive to improve our products, we reserve the right to make changes without

notification.

Page 6

4.0 INSTALLATION AND SET-UP

CAUTION: THIS SECTION DISCUSSES INSTALLATION AND SET-UP PROCEDURES.

PLEASE READ ALL SECTIONS OF THIS MANUAL THOROUGHLY BEFORE OPERATING

THIS MACHINE.

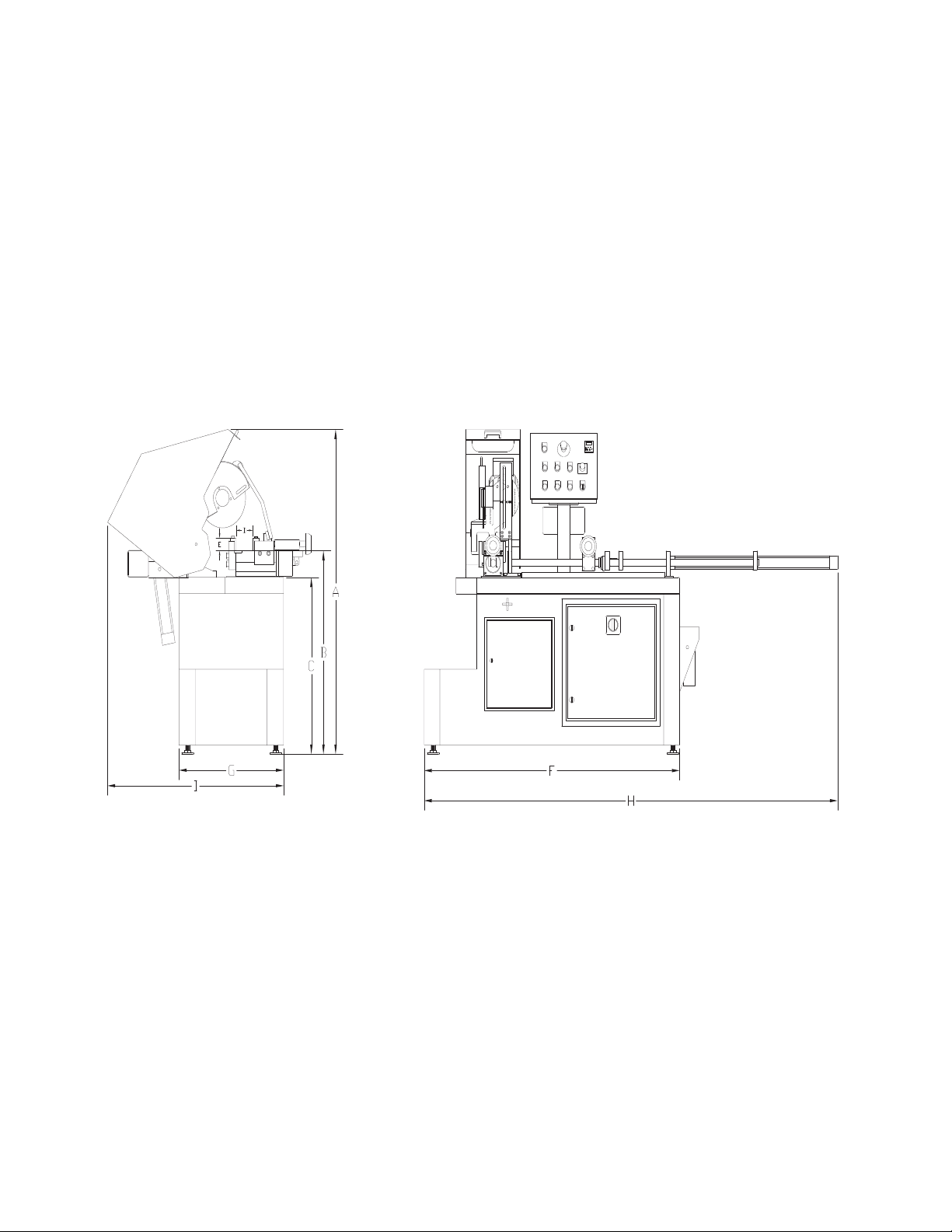

4.1 PHYSICAL DIMENSIONS

SEE FIGURE 1 ON THE FOLLOWING PAGE.

DIMENSIONS INCHES CM

A HEIGHT 65 165

B FLOOR TO VISE 38.5 98

C BASE HEIGHT 35 89

D VISE OPENING 3-5/8 9.2

E VISE DEPTH 2-1/4 5.7

F BASE WIDTH 61 155

G BASE DEPTH 25 64

H WIDTH 100 254

I DEPTH 44 112

WEIGHT 1,750 LB. 795 KG.

Page 7

FIGURE 1

Page 8

4.2 MACHINE INSTALLATION

SEE FIGURE 2 ON THE FOLLOWING PAGE.

This machine is shipped on a pallet and can be moved to the installation location by means of a forklift.

CAUTION: THIS MACHINE IS TOP HEAVY AND MUST BE MOVED WITH CARE, ON

HARD FLAT SURFACES ONLY.

USE THE FOLLOWING STEPS TO INSTALL THE MACHINE:

1. Select a location for the machine that allows adequate room for any length of material that

you may want to cut. Leave adequate space behind the machine and on either end, for set-up

and maintenance.

2. Lift the machine off of the shipping pallet, using a forklift.

3. Place the machine in its final location and level it, using the leveling pads. For this machine to

function properly, it is very important that it is level. Any supply tracks used with this machine

must also be level and aligned with the vises on the machine.

4. Install the shuttle cylinder on the machine.

NOTE: MACHINES EQUIPPED WITH A DIGITAL READOUT WILL ALREADY HAVE THE

CYLINDER INSTALLED.

5. We strongly recommend that you anchor the machine and supply tracks to the floor, with the

anchor plates provided with the machine.

6. Connect the main air and electrical supply lines to the machine. To connect the air, slide the

shuttle valve (I) down to the closed position and connect the incoming supply line. (DO NOT

TURN THE AIR ON YET.) This machine requires a minimum of 90 PSI and may require up to

130 PSI, depending on your application. The electrical supply lines must be connected by a

qualified electrician. The supply lines connect to the top of the main disconnect switch (J) located

in the lower base cabinet. Make sure that your plant phase and voltage correspond to the phase

and voltage of the machine before connecting the electrical supply.

CAUTION: DO NOT POWER THE MACHINE UNTIL THE MACHINE INSTALLATION IS

COMPLETE AND UNTIL YOU HAVE READ ALL OF THE SECTIONS OF THIS MANUAL!

Page 9

FIGURE 2

Page 10

4.3 ELECTRICAL REQUIREMENTS

CAUTION: TO PREVENT DAMAGE TO THE MACHINE AND DANGER TO THE

OPERATOR, ALL ELECTRICAL CONNECTIONS MUST BE MADE BY A QUALIFIED

ELECTRICIAN. THIS MACHINE OPERATES WITH LIQUID COOLANT AND MUST BE

GROUNDED IN ACCORDANCE WITH NATIONAL ELECTRIC CODES.

All machines are wired for three phase power. The motors are dual voltage. If the machine is not the

same voltage as your plant voltage, you will have to rewire the motor and the coolant pump.

To insure satisfactory performance, the supply voltage should be (+ or -) 10% of the motor voltage

rating. Check the motor data tag for full load current requirements. Single phase motors are not

available.

NOTE: MACHINES THAT ARE WIRED FOR 208 VOLT/3 PHASE REQUIRE AN

ADDITIONAL STEP UP TRANSFORMER. FOR ADDITIONAL INFORMATION, SEE

SECTION 11.10.

THE ELECTRICAL DIAGRAM FOR THIS MACHINE IS IN SECTION 14.0.

For supply lines ten feet (304 cm) or shorter, we recommend 12 gauge wire. For lines longer than ten

feet (304 cm), we recommend 10 gauge wire. We do not recommend supply lines over twenty feet (609

cm) in length.

CPO-315-HFA-LT (11-177 RPM)

MOTORVOLTAGE FULL LOAD CURRENT HORSEPOWER

208 22 5

230 20 5

460 10 5

Page 11

The CPO-315-HFA saw is equipped with a mist coolant system. A flood coolant system is an

option for this saw.

The container for the coolant is located on the inside of the front door of the saw.

The coolant should be mixed in a ratio of one part coolant to seven parts water. We recommend

using our P/N 075751 coolant (1 gallon) for most applications. This is also available in 5 gallon

bucket as P/N 075752 and in a 55 gallon drum as P/N 075754. This coolant can be mixed stronger

if needed.

When cutting alloy steels such as stainless steel, we recommend our special mix coolant designed

for these applications: P/N 075756 in a 1 gallon jug and P/N 075757 in 5 gallon bucket.

We recommend pre-mixing the coolant before adding it to the saw.

FOR ADDITIONAL INFORMATION ON AVAILABLE COOLANTS, SEE SECTION 12.2.

4.4 COOLANT SYSTEM

5.0 MACHINE START-UP

Before starting this machine, take the time to review the operator.s manual thoroughly, to

familiarize yourself with all of the functions of the machine.

We strongly urge you to follow OSHA directive CFR-1910.147 (effective 09-09-90) regarding

lock-out, tag-out procedures. Keep in mind that the directive refers to all hazardous energy

sources, not just electrical.

The air supply must also be disconnected and locked or tagged.

Do not install a blade on the saw until after it has been powered and cycled several times.

Once the machine has been powered, check the rotation of the spindle. There is an arrow on

the guard showing the proper rotation. If the rotation is not correct, the electrician will have

to switch two of the three line wires.

Page 12

5.1 CONTROL PANEL FUNCTIONS

The following section gives a brief description of each of the control panel switches and buttons.

Before powering the machine, please familiarize yourself with the location and the function of

each of these items. SECTION 7.0 will describe how to set the machine up for an operation.

SEE FIGURE 3 BELOW.

FIGURE 3

Page 13

5.1A MAIN POWER SWITCH

This is the main power disconnect switch for the machine and it should be locked or tagged in the OFF

position any time that maintenance or service work is being performed. Maintenance or service work on

the electrical controls must be performed by qualified personnel. This switch must be in the ON position

to operate any of the other control panel functions.

There is a red power indicator light (O) on the control panel. This light indicates that this switch is in

the ON position.

CAUTION: THIS SWITCH DOES NOT DISCONNECT THE AIR SUPPLY TO THE

MACHINE. ANY TIME THAT MAINTENANCE OR SERVICE WORK IS PERFORMED

ON THE MACHINE, THE AIR SUPPLY MUST ALSO BE DISCONNECTED AND TAGGED

OR LOCKED OUT.

5.1B MOTOR CONTROL SWITCH

This switch is used to turn the saw motor on.

5.1C POWER UP SWITCH

This switch energizes the system for the rest of the control panel functions. This switch will also

start the saw motor. The motor will not start unless the MAIN POWER switch (A) is on and the

AUTOMATIC/ MANUAL SWITCH (I) is in the manual position. The MOTOR SWITCH (B) must

be in the ON position for the saw motor to start.

5.1D EMERGENCY STOP SWITCH

This switch stops the saw motor and allows the head to return to the up position. The emergency

stop switch does not release the material vise or the air pressure. Once this switch has been used, the

operator must restart the machine in the manual position and go through the startup procedure again.

For complete instructions on changing bars of material, REFER TO SECTION 7.0.

Page 14

5.1E HEAD UP

This button is used to abort a cut in mid cycle when the AUTOMATIC/MANUAL SWITCH is in the

MANUAL position. This button is inoperable when the machine is in the AUTOMATIC position.

5.1F HEAD DOWN

This button is also used to set the overall stroke of the machine and to make manual cuts.

5.1G HITCH SELECTOR

This switch is used to select the number of hitches the shuttle vise makes before the saw makes a cut.

POSITION 1 is for parts from 0 to thirty inches in length. POSITION 2 is for parts from thirty to sixty

inches. POSITION 3 is for parts from sixty to ninety inches.

5.1H CYCLE/START BUTTON

This button starts the machine cycle. The CYCLE/START button is used to make trim cuts and set-up

cuts prior to starting the automatic operation. It is also used to start the automatic operation once all of

the test cuts are done.

5.1I AUTOMATIC/MANUAL SWITCH

This switch must be in the MANUAL position to start the machine, to make trim cuts and to set the

product lengths. After the machine has been set up and sample cuts have been made, this switch is

moved to the AUTOMATIC position. Any time that the saw is in the AUTOMATIC position, this switch

can be turned to the MANUAL position. When it is turned to the MANUAL position, the machine will

complete the cycle it’s on and stop when the head reaches the up position. The saw motor will continue to

run when this switch is used to stop the automatic operation of the machine. When this switch is in the

AUTOMATIC position and the machine runs out of product, the operator must reset the machine’s

operation. For instructions on changing bars of material, REFER TO SECTION 7.0. When this switch is

used to stop the automatic operation, you can start the automatic operation again by depressing the

TRIM/TEST SWITCH (J) and then, the CYCLE button (H). The machine will trim and cut one part.

You can then switch the AUTOMATIC/MANUAL SWITCH to the AUTOMATIC position and press

the cycle button again. The machine will continue with the automatic operation.

Page 15

5.1J TRIM/TEST

This button is used to do first part cuts prior to running the machine in the automatic position. With the

AUTO/MANUAL switch in the MANUAL position, press the TRIM/TEST button (J) and then, press

the CYCLE button (H). The saw will trim and then cut one part and return to the up position. Make

whatever adjustments that you need to and depress the CYCLE button (H) again and the saw will cut one

more test piece. After you are satisfied with all of the settings, place the AUTO/MANUAL switch (I) in

the AUTOMATIC position and press the CYCLE button again. The saw will start the automatic

operation.

5.1K COOLANT PUMP SWITCH

This switch starts the machine’s coolant pump.

5.1L VARIABLE MOTOR SPEED CONTROL

This switch is one of the most important standard features on this machine. This switch gives you a wide

range of cutting speeds. The range is from 11 RPM to 177 RPM. With this feature, you are able to match

the blade speed to the material, which greatly increases blade life and reduces vibrations. When this

switch is in the 50 percent position, the machine runs at 83 RPM. With the switch at the 0 percent

position, the RPM’S will be 11 and with the switch at the 100 percent position, the RPM’S will be 177.

5.1M COUNTER

The Parts Counter is programmed at the factory to count up. If you want to set the counter to count

down, please contact the factory. To enter a pre-set value in the counter, press any of the white keys

numbered 1 to 5. The pre-set value will appear on the screen. Use the white keys to set the total number

of pieces that you want to cut. After a three second delay, the pre-set value screen will disappear. The

counter will then display the number of pieces cut as the saw runs. When the value on the screen reaches

the pre-set value, the machine will stop. If you press the red button, the count value displayed on the

screen will be zeroed out. The reset button does not erase the pre-set value. To change the pre-set value,

press any white button and the pre-set value will appear on the screen. For the machine to run in the

automatic mode, there must be a pre-set value on the counter.

Page 16

5.1N FEED RATE CONTROL

This valve controls the down feed rate of the saw head and is used in the set-up of the up and down

stroke control of the saw head. To adjust the down feed cutting rate of the head, turn the control all the

way to the right (clockwise) and then, open it one turn. The down feed rate is set by sound. Start with a

slow rate and gradually increase it until the blade chatters, then back it off slightly. Selecting the

proper blade and the condition of the blade will effect the down cutting rate dramatically. There is also

a down feed regulator, located on the machine, that provides constant down pressure on the material.

5.1O POWER INDICATOR LIGHT

This light indicates that the main switch (A) is on and that there is power to the control panel.

6.0 MACHINE OPERATION

6.1 SELECTING THE PROPER CUTTING SPEED

In cold sawing, there is no such thing as a general purpose blade. To achieve the best results from your

saw, proper blade selection is important. Each saw is shipped with a pitch (number of teeth) calculator,

which will help to determine the proper blade for your application.

When sawing flat stock or rectangular solid sections, determine the thickest section that will be cut and

use the equivalent square size on the pitch calculator to determine the proper blade.

The CPO-315-HFA is designed to use a maximum 12-1/2 inch (315mm) diameter blade. 10-3/4 inch

blades are also available for this machine.

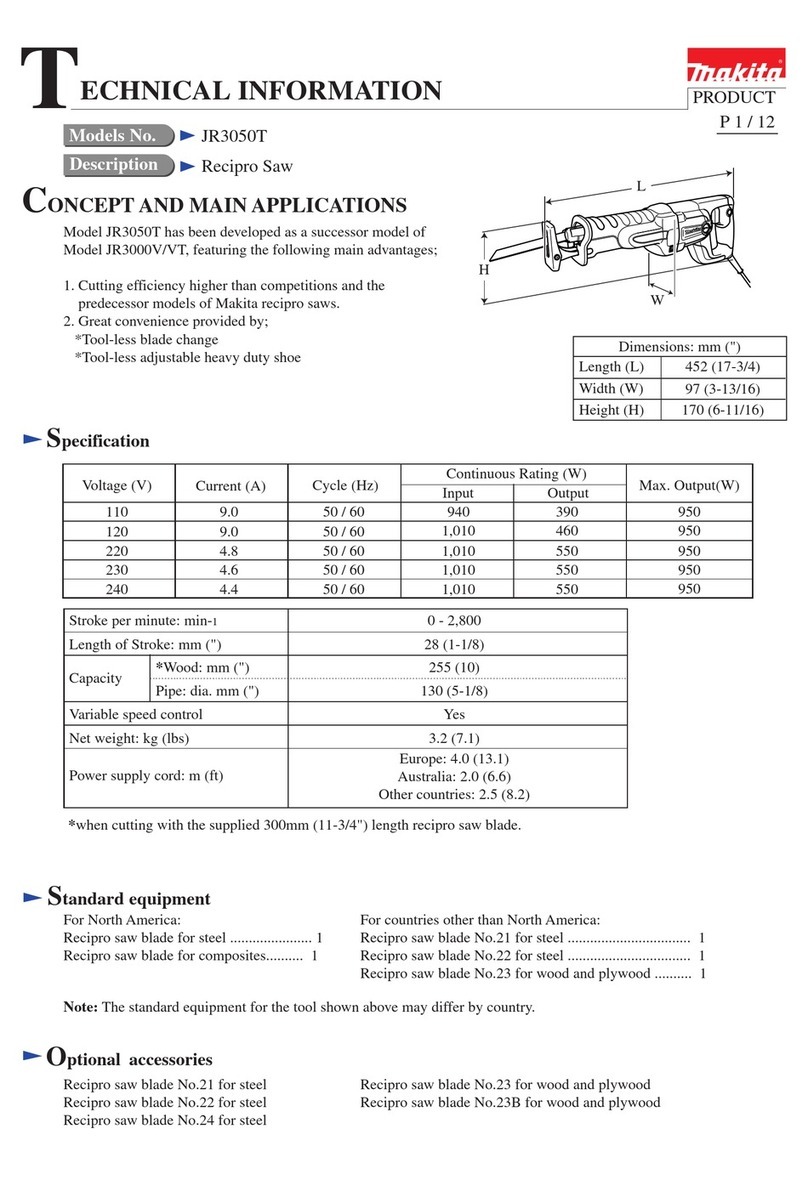

The chart below gives the surface feet per minute for the various spindle RPM’S:

BLADE DIAMETER SURFACE FEET PER MINUTE

INCH MM 18 88 176 RPM’S

10-3/4 275 50 247 495

12-1/2 315 59 287 576

The proper blade speed is also important. The High speed (176 RPM) is recommended for thin walled

tubes and nonferrous tubes and profiles. Some materials will require test cuts at both speeds to

determine the best speed for the application. The Low speed, 18 RPM, is recommended for solid sections

of mild steel and alloy tubes.

Page 17

THIS PAGE LEFT BLANK INTENTIONALLY.

Page 18

6.2 BLADE INSTALLATION

SEE FIGURE 4 BELOW.

FIGURE 4

Page 19

CAUTION: USE ONLY HIGH SPEED STEEL BLADES DESIGNED FOR THIS MACHINE.

DO NOT MODIFY ANY BLADE TO FIT THIS MACHINE. DO NOT USE BLADES

DESIGNED FOR THIS MACHINE ON ANY OTHER EQUIPMENT. THE MAXIMUM RPM’S

FOR THESE BLADES ARE 600 FOR THE 12-1/2" AND 700 FOR THE 10-3/4".

The CPO-315-HFA saw is designed to use a maximum 12-1/2 inch (315mm) diameter blade. The arbor

size is 40mm with four 12mm pins spaced at 65mm.

BEFORE INSTALLING THE BLADE, make sure that the power to the machine is off.

USE THE FOLLOWING STEPS TO INSTALL A BLADE:

An 8mm hex key wrench (D), shipped with each machine, is required to change blades.

1. Raise the movable hood guard to the open position.

2. Release the upper stroke control stop (H) and allow the head to travel to its full up position.

3. Back off the blade guide bolts (G), if they are being used, and slide them out to the end of the slots.

4. Remove the blade bolt (B) and the blade flange (C).

5. Check the blade flange, the blade and the saw spindle for any chips or nicks that will affect the

way the blade seats.

6. Install the blade. Make sure that the pin holes in the blade line up to the holes in the spindle.

7. Replace the blade flange (C) and start the bolt (B) into the spindle.

8. Before locking the blade in position, the back lash must be taken up. To take up the back lash,

rotate the bottom of the blade toward you until it seats against the drive pins.

CAUTION: THE BLADES ARE VERY SHARP AND CARE MUST BE TAKEN WHEN

REMOVING THE BACK LASH. DO NOT GRIP THE CUTTING EDGE OF THE BLADE

BARE HANDED. THE BACK LASH MUST BE TAKEN UP EVERY TIME A BLADE IS

CHANGED.

9. After taking up the back lash, tighten the blade bolt (B).

Table of contents

Other Scotchman Saw manuals

Scotchman

Scotchman SU-280-G User manual

Scotchman

Scotchman CPO-315-RFA-NF User manual

Scotchman

Scotchman CPO-350-NF-5HP User manual

Scotchman

Scotchman SU-280-G User manual

Scotchman

Scotchman CPO-315-HFA-NF User manual

Scotchman

Scotchman GAA-500-90 NF User manual

Scotchman

Scotchman CPO-275 User manual

Scotchman

Scotchman SU-280 User manual

Scotchman

Scotchman CPO-315-HFA-CNC User manual

Scotchman

Scotchman CPO 350 User manual