1.0 INTRODUCTION

1.2 WARRANTY

Page 3

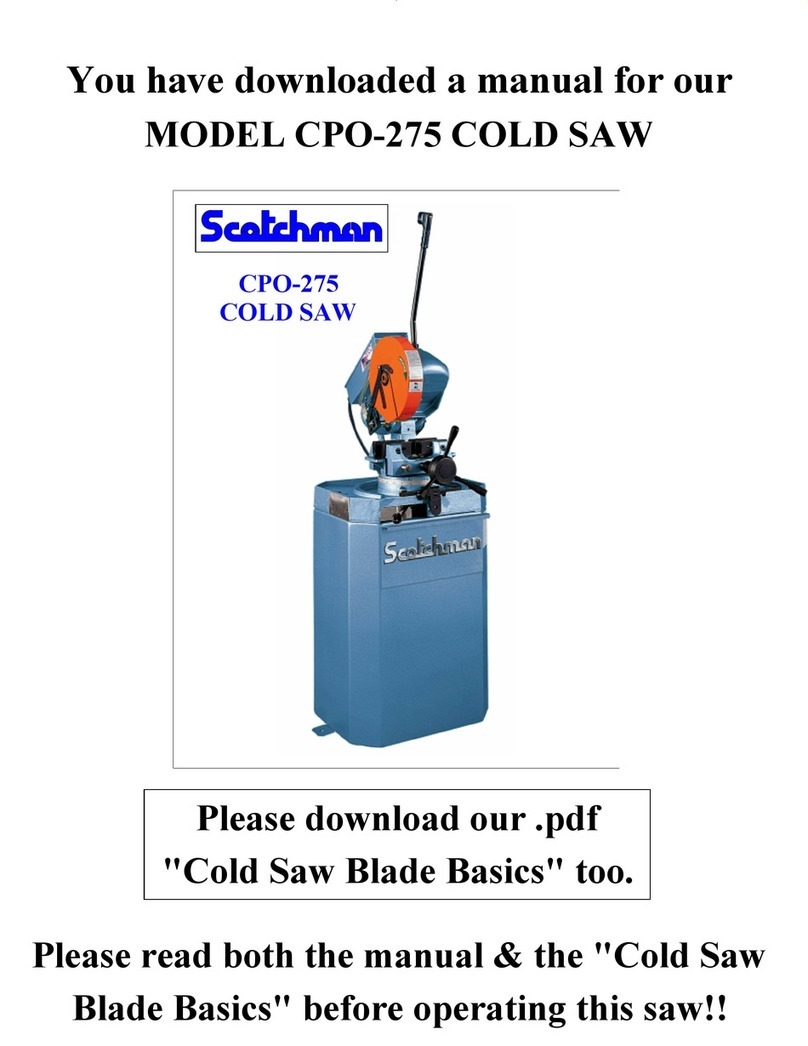

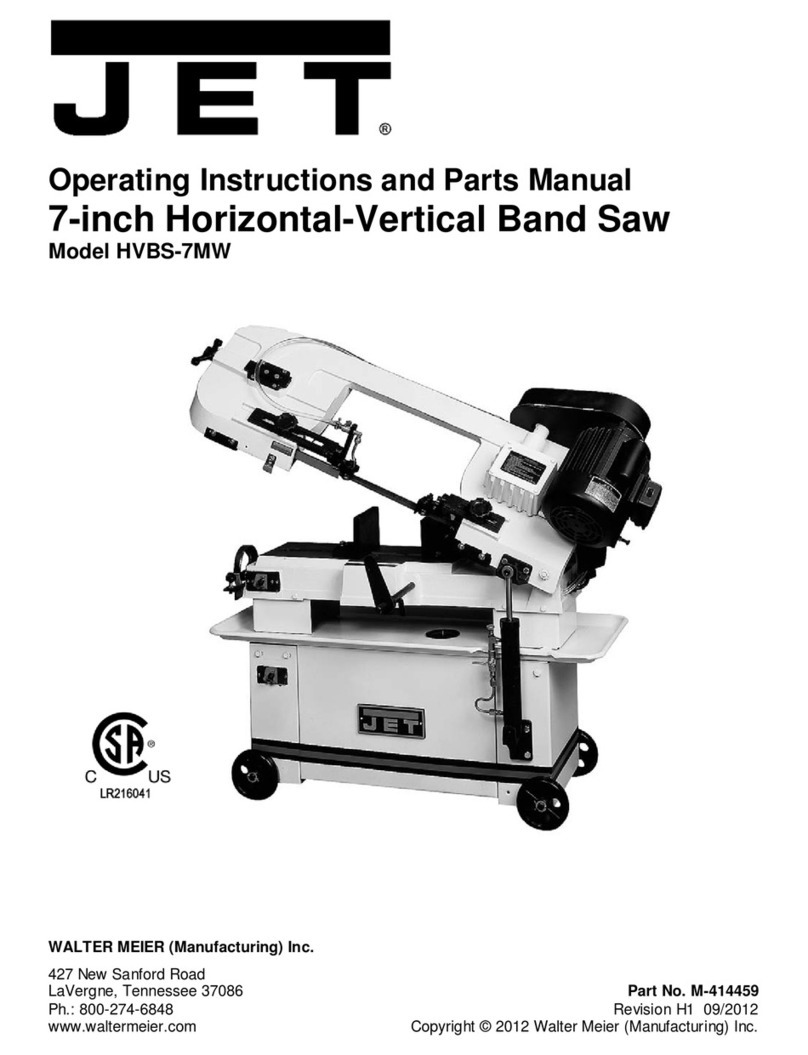

Scotchman's Utility Band Saw features a metered feed rate allowing for quick and effortless

cuts without operator assistance! The SU-280G (Gravity Feed) is a scaled-down but rugged

metal cutting band saw that combines the cutting of a traditional band saw with the flexibility

& accuracy of a cold saw. This band saw can easily cut through round material up to 8" in

diameter & features a swing head with 30 degrees (right) of mitering capability without

material movement.

1.1 SAFETY PRECAUTIONS

Scotchman Industries, Inc. will, within three years of the date of purchase, replace F.O.B. the factory

or refund the purchase price for any goods which are defective in materials or workmanship, provided

the buyer, at the seller’s option, returns the defective goods freight and delivery prepaid to the seller,

which shall be the buyer’s sole and exclusive remedy for defective goods. This warranty does not apply

to machines and/or components which have been altered, changed or modified in any way or subjected

to abuse and abnormal use, inadequate maintenance and lubrication or subjected to use beyond the

seller’s recommended capacities and specifications. In no event shall the seller be liable for labor cost

expended on such goods or consequential damages. The seller shall not be liable to the purchaser or

any other person for loss or damage directly or indirectly arising from the use of the goods or from any

other cause. No officer, employee or agent of the seller is authorized to make any oral representations

or warranty of fitness or to waive any of the foregoing terms of sale and none shall be binding on the

seller. Any electrical changes made to the standard machine due to local electrical code variation must

be paid by purchaser. As we constantly strive to improve our products, we reserve the right to make

changes without notification.

1. The operators of this machine must be qualified and well trained in the operation of the

machine. This manual is not intended to teach untrained personnel how to operate

2. All of the guards and awareness barriers must be installed on the machine and kept in good

working order.

3. Never place any part of your body into or under any of the machine’s moving parts.

4. Wear the appropriate personal protective equipment. Safety glasses are required at all

times. Steel-toed shoes and leather gloves are also recommended.

5. Always disconnect and lock out the power when performing maintenance work on the

6. Never operate this machine with a dull or damaged saw blade. Replace worn saw blades

promptly.

7. Practice good housekeeping. Keep the area around the machine clear and well lit.

8. Never modify this machine in any way without the written permission of the manufacturer.

9. Never leave this machine running unattended.

10. Set up a program of routine inspections and maintenance. Make all repairs and adjustments

in accordance with the manufacturer’s instructions.

machine.

machinery.