Shenzhen SCOTLE Technology

-----------------------------------------------------------------------

Email:sales@scotle.com Tel:86075589378931 http://www.scotle.com/

------------------------------------------------------------------------------------------------

PID control and can get to the best soldering effect.

9. The setting of the heating temperature, time, slope, cooling and vacuum

suction can all be finished through the TFT touch screen.

10. Top and bottom temperature zones can be set 6 to 8 temperature files and

can store more than thousands of profiles for different BGA reworking.

Users can select, analyze, set and certify those profiles on the touch screen.

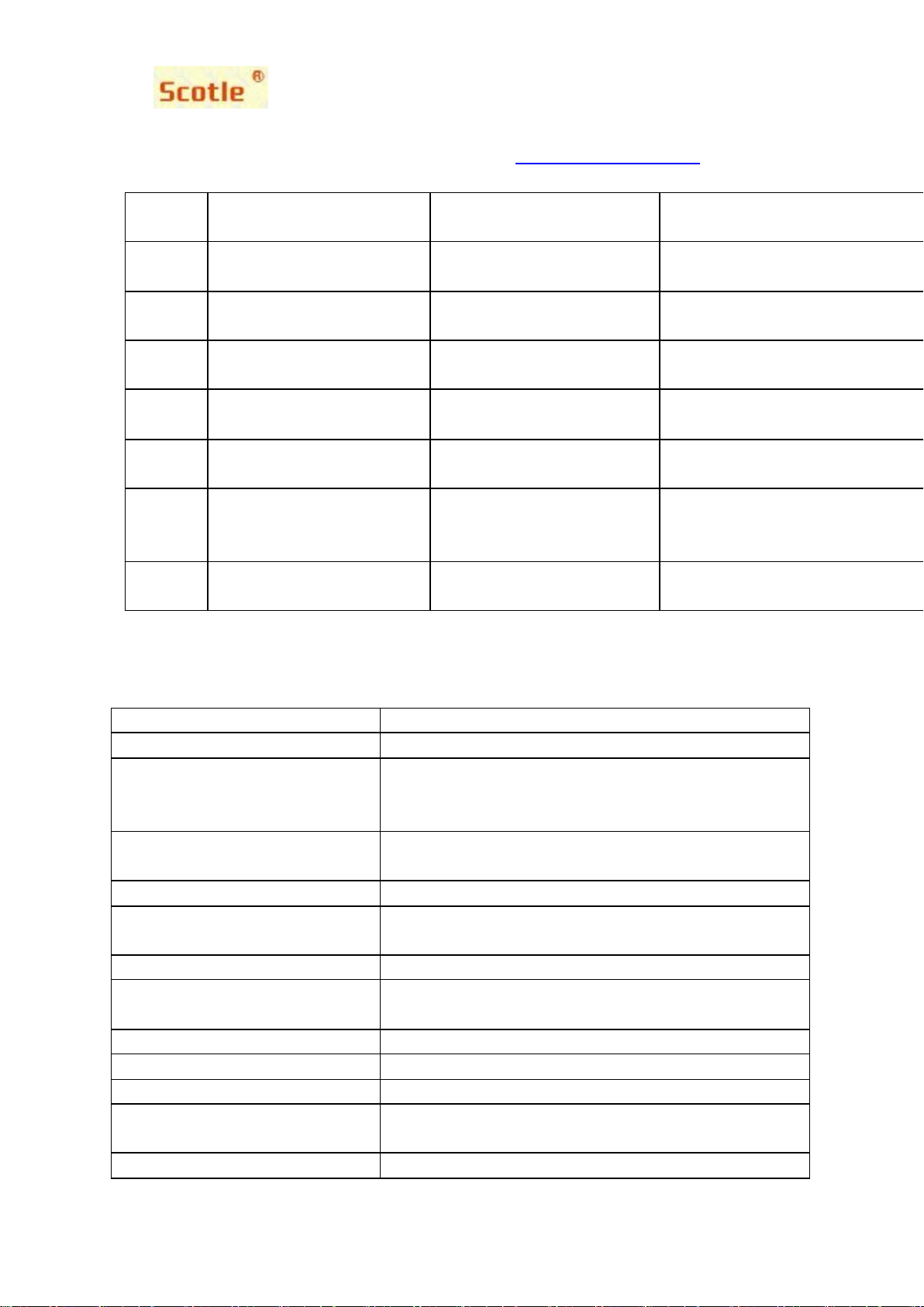

11. Scotle-HR460C applies high power cross flow fan cooling system uses which

can cooling the PCB quickly to avoid deformation. Scotle HR460C is with

built-in vacuum pump and external vacuum suction pen which facilitate

removing the BGA chip time.

12. Scotle HR460C is equipped with alarming function which will alarming 5-10

seconds in advance before the soldering or desoldering finished.

When the top and bottom stop heating, the cooling system starts working

until the BGA rework station down to room temperature, which can protect

the machine from aging.

13. Scotle HR460C is equipped with external camera system, and users can saw

and detect the melting process.