i

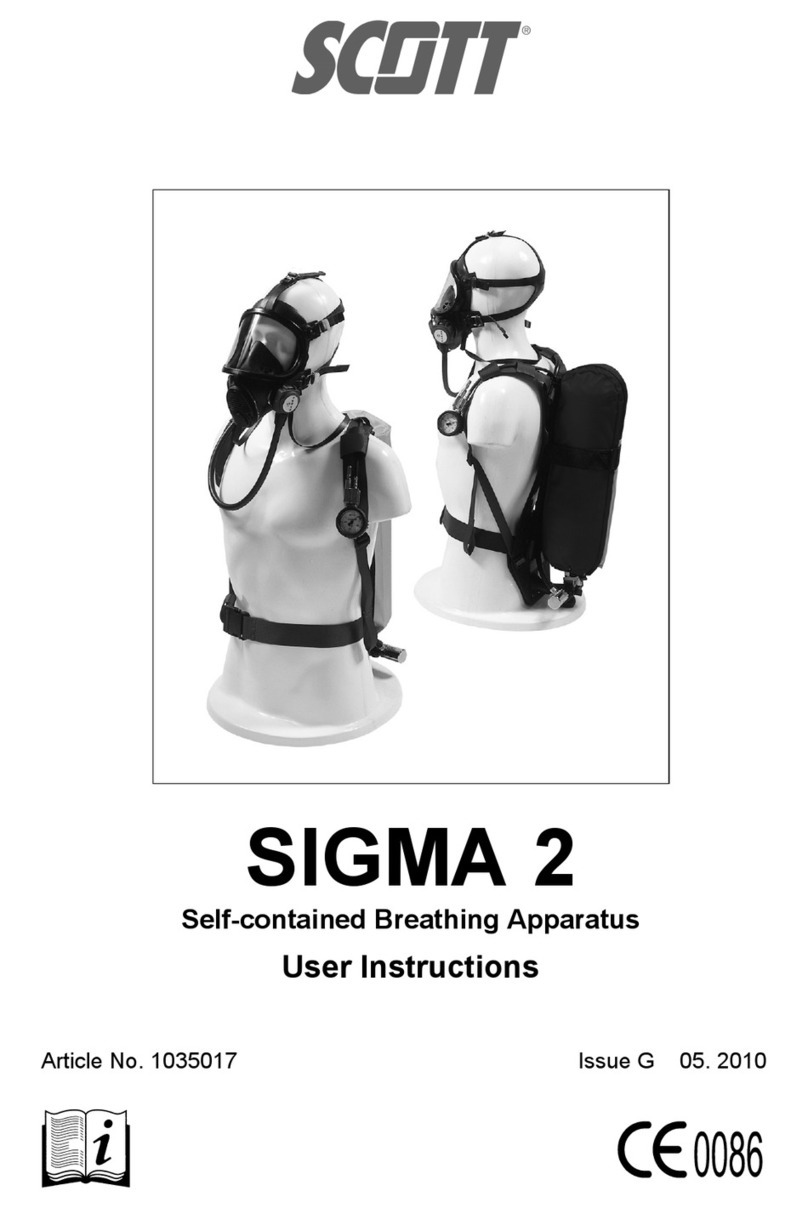

Self-contained Breathing Apparatus

Contents

WARNINGS................................................................................................................................................................. ii

1. INTRODUCTION.............................................................................................................................................1

1.1 IMPORTANT ...............................................................................................................................................1

1.2 BREATHABLE AIR......................................................................................................................................1

1.3 COMPRESSED AIR AIRLINE SUPPLIES...................................................................................................1

1.4 APPARATUS DURATION ...........................................................................................................................2

1.5 PERSONNEL TRAINING ............................................................................................................................2

1.6 SERVICING.................................................................................................................................................2

1.7 SPARE PARTS AND ACCESSORIES ........................................................................................................3

1.8 NOTIFIED BODIES.....................................................................................................................................3

2. TECHNICAL DESCRIPTION ..........................................................................................................................3

2.1 PNEUMATICS.............................................................................................................................................4

2.2 REDUCER...................................................................................................................................................4

2.3 DEMAND VALVE ........................................................................................................................................4

2.4 FACEMASK.................................................................................................................................................5

3. QUALITY ATTRIBUTES .................................................................................................................................5

3.1 NOTIFIED BODIES.....................................................................................................................................5

4. CHECK APPARATUS.....................................................................................................................................6

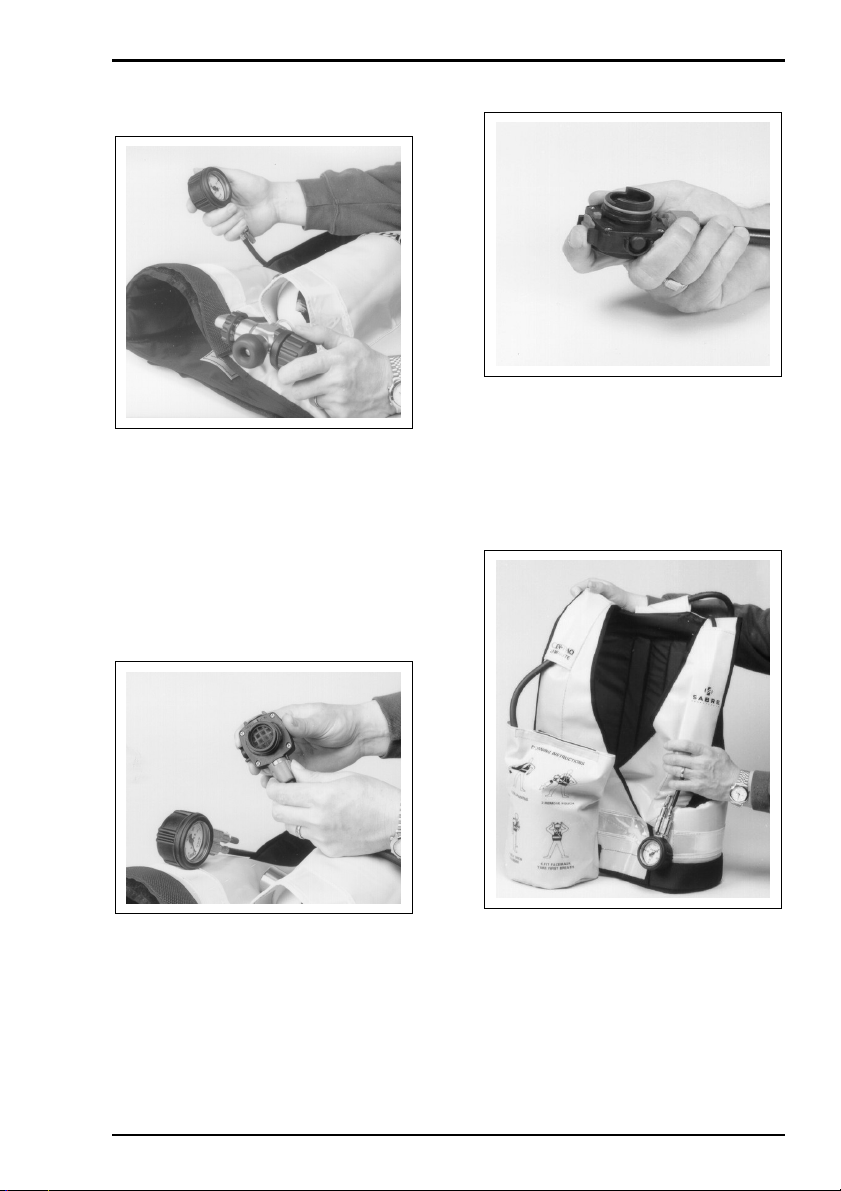

4.1 FIT FULLY CHARGED CYLINDER.............................................................................................................6

4.2 CHECK DEMAND VALVE...........................................................................................................................6

4.3 CHECK CYLINDER PRESSURE / LEAK TEST..........................................................................................7

4.4 WHISTLE TEST..........................................................................................................................................7

4.5 FIT CLEAN FACEMASK .............................................................................................................................7

4.6 CHECK APPARATUS .................................................................................................................................7

5. DONNING & OPERATING PROCEDURE – Standard Apparatus ...............................................................8

5.1 DON APPARATUS......................................................................................................................................8

5.2 CHECK DEMAND VALVE...........................................................................................................................8

5.3 OPEN CYLINDER VALVE...........................................................................................................................9

5.4 DON FACEMASK........................................................................................................................................9

5.5 POSITIVE PRESSURE TEST.....................................................................................................................9

5.6 WHISTLE / FACESEAL TEST ....................................................................................................................9

5.7 CHECK CYLINDER PRESSURE ..............................................................................................................10

6. DONNING & OPERATING PROCEDURE – Airline Apparatus..................................................................10

6.1 DON APPARATUS....................................................................................................................................10

6.2 CHECK DEMAND VALVE.........................................................................................................................11

6.3 CONNECT SUPPLY..................................................................................................................................11

6.4 FIT FACEMASK ........................................................................................................................................11

6.5 POSITIVE PRESSURE TEST...................................................................................................................11

6.6 FACESEAL TEST......................................................................................................................................12

6.7 OPERATING CYLINDER SUPPLY ...........................................................................................................12

7. DOFFING INSTRUCTIONS ..........................................................................................................................13

7.1 REMOVE FACEMASK ..............................................................................................................................13

7.2 TURN OFF CYLINDER VALVE / DISCONNECT SUPPLY.......................................................................13

7.3 REMOVE APPARATUS ............................................................................................................................14

7.4 CLEAN & TEST APPARATUS ..................................................................................................................14

8. AFTER USE ..................................................................................................................................................14

8.1 CLEAN FACEMASK..................................................................................................................................14

8.2 CLEAN APPARATUS................................................................................................................................15

8.3 CHECK APPARATUS ...............................................................................................................................15

8.4 RECORD TEST DETAILS.........................................................................................................................15

8.5 STORAGE.................................................................................................................................................16

9. SCHEDULED MAINTENANCE.....................................................................................................................16

9.1 MONTHLY.................................................................................................................................................16

9.2 ANNUALLY ...............................................................................................................................................16

Registered office: Scott Health and Safety Limited, Pimbo Road, West Pimbo,

Skelmersdale, Lancashire, WN8 9RA, United Kingdom.