Page 10 of 36 P/N 595225-01 Rev C 4/12

NOTE

DO NOT LIFT, TRANSPORT, OR HOLD THE

CYLINDER BY THE HAND WHEEL.

AIR CYLINDER INSTALLATION

The SCOTT RIT-PAK III portable air supply is available in three pressure models for use

with the following air cylinders:

• RIT-PAK III 2216 psi for use with SCOTT 2.2 cylinders with an air supply

rated at 30 minutes.

• RIT-PAKIII4500psiforusewithSCOTT4.5cylinderswithanairsupply

ratedat30,45,or60minutes

• RIT-PAKIII5500psiforusewithSCOTT5.5cylinderswithanairsupply

ratedat30,45,60,or75minutes

Other cylinders may be used provided:

• theymatchtheairpressureratingthatthemodelwasdesignedtouse,

• theydonotexceedthesizecapacityofthecarryingbag,

• they are equipped with the proper CGA fitting to attach to the cylinder

coupling. NOTE

USE ONLY BREATHING AIR CYLINDERS THAT FIT IN THE CARRYING BAG.

IF THE CYLINDER DOES NOT FIT FULLY IN THE CARRYING BAG, DO NOT

USE THE CYLINDER.

CYLINDER INSTALLATION

Install the cylinder and valve assembly in the RIT-PAK III portable air supply as follows:

1. Open the top of the carrying bag by releasing the hook-and-loop fastener

strips on the pressure reducer compartment and on the long edge of the

cylinder compartment cover.

2. Loosen the two cylinder straps by lifting the ends and releasing the hook-

and-loop fastener and lay the ends of the straps out each side of the bag.

3. Inspect the equipment and verify that it is in suitable condition for use. Refer

to the REGULAR OPERATIONAL INSPECTION of this instruction. If any dam-

age is found, remove the unit from service and tag for repair by authorized

personnel.

CYLINDER INSPECTION

1. Check the latest cylinder hydrostatic test date to ensure it is current. All breathing

air cylinders used SCOTT respirator equipment must be visually inspected regularly

and hydrostatically tested by a licensed cylinder re-tester in accordance with the

appropriate US Department of Transportation (DOT) specification or applicable DOT

exemption, or in accordance with the appropriate Transport Canada (TC) Permit of

Equivalent Level of Safety. For a complete listing of retest date requirements, refer

to the current revision of Safety Precautions for AIR-PAK Cylinders, Scott P/N 89080-

01, available on request from Scott Safety. Composite cylinders (those cylinders

utilizing fiber over wrap) must be tested in accordance with the DOT exemption

status up to the maximum life of fiber over-wrapped cylinders which, at the time of

thepublicationofthisinstruction,is15yearsfromthedateofmanufacture.Thedate

of manufacture marked on the cylinder is also the date of the first hydrostatic test.

It is the responsibility of your organized respiratory protection program to arrange

for visual inspection and hydrostatic testing of cylinders by a licensed re-tester.

2. Visually inspect cylinder and valve assembly for physical damage such as dents

or gouges in metal or in composite wrapping. Cylinders which show physical

damage or exposure to high heat or flame, such as paint turned brown or black,

decals charred or missing, pressure gauge lens melted or elastomeric bumper

distorted, and cylinders which show evidence of exposure to chemicals such

as discoloration, cracks in the cylinder or the composite wrapping or gel top

coat, peeling of the outer layers of the composite wrapping and/or bulging of

the cylinder wall, shall be removed from service and emptied of compressed air.

Refer to current applicable publications on compressed gas cylinder inspection

available from Compressed GasAssociation Inc., 1725 Jefferson Davis Hwy.,

Suite 1004,Arlington, VA 22202, (703-412-0900) for a detailedexplanation of

cylinder inspection procedures.

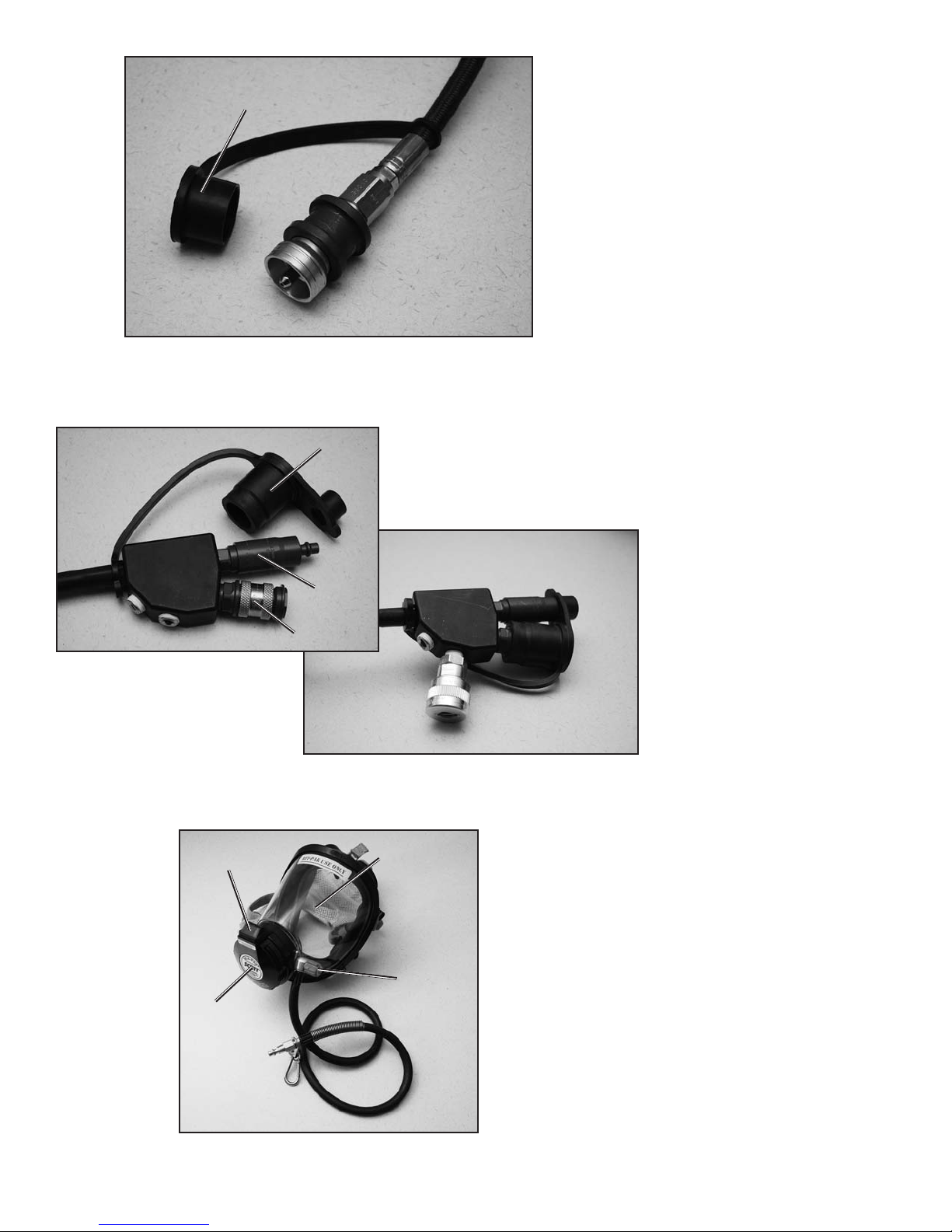

3. Check cylinder pressure gauge for “FULL” indication. If cylinder pressure is less

than “FULL,” replace with a fully charged cylinder. See FIGURE 1. Charge cylin-

derswith breathing air rated asGrade D orbetter perCGA specification G-7.1

withadewpointof-65° F/-54° Corlower.DONOTFILLWITHOXYGEN.

The SCOTT RIT-PAK III portable air supply is designed to fit only the following

SCOTT cylinders:

• SCOTT2216psi2.2cylinderswithanairsupplyratedat30minutes.

• SCOTT4500 psi4.5 cylinderswith an airsupply ratedat 30,45, or

60 minutes

• SCOTT5500 psi 5.5 cylinderswith an air supply ratedat 30, 45, 60, or

75minutes

WARNING

NEVER USEA CYLINDER WHICH EXHIBITS

DAMAGE CONDITIONS. CYLINDERS

WHICH EXHIBIT DAMAGE CONDITIONS

MAY SUDDENLY LEAK OR RUPTURE IF

CHARGED WITH COMPRESSED AIR AND

CAUSE SERIOUS INJURY OR DEATH.

WARNING

CYLINDER MUST HAVE A CURRENT

HYDROSTATIC TEST DATE. IMPROPERLY

INSPECTED CYLINDERS THAT ARE

DAMAGED MAY SUDDENLY LEAK

OR RUPTURE IF CHARGED WITH

COMPRESSED AIR AND CAUSE SERIOUS

INJURY OR DEATH.

WARNING

DO NOT USE OXYGEN! SUPPLYING THE

RESPIRATOR WITH OXYGEN MAY CAUSE

SICKNESS OR MAY CAUSE A FIRE OR

EXPLOSION RESULTING IN SERIOUS

INJURY OR DEATH.

WARNING

USE ONLYAIR DRIED TOADEW POINT OF

-65° F / -54° C OR LESS. MOISTURE IN AIR

UNDER PRESSURE CAN FREEZE EVENAT

AMBIENT TEMPERATURES WELL ABOVE

+32° F / 0° C. FAILURE TO ENSURE THE

AIR SUPPLY IS FREE OF CONDENSED

MOISTURE MAY CAUSE FREEZING AND

PARTIAL OR COMPLETE FAILURE OF

THE RESPIRATOR LEADING TO SERIOUS

INJURY OR DEATH.

WARNING

THE USE OF ANY AIR CYLINDER WITH

A DIFFERENT PRESSURE FROM THE

PRESSUREINTENDEDFORUSEWITHTHE

SPECIFIC SCOTT RIT-PAK III PORTABLE

AIR SUPPLY MODEL BEING USED WILL

RESULT IN CHANGES TO THE BEHAVIOR

OF THE REMOTE GAUGE AND/OR THE

END-OF-SERVICEALARMS. SEE THE USE

OFALTERNATE CYLINDERS SECTION OF

THIS INSTRUCTION. A PERSON MUST

MONITOR THE AIR PRESSURE GAUGE

ON THE CYLINDER TO DETERMINE

THE AIR REMAINING IN THE CYLINDER.

FAILURE TO PROPERLY MONITOR THE

AIR REMAINING IN THE CYLINDER MAY

RESULT IN SUDDEN AND UNEXPECTED

TERMINATION OF THE AIR SUPPLY TO

THE USER OF THE RESPIRATOR AND

LEAD TO SERIOUS INJURY OR DEATH.