10

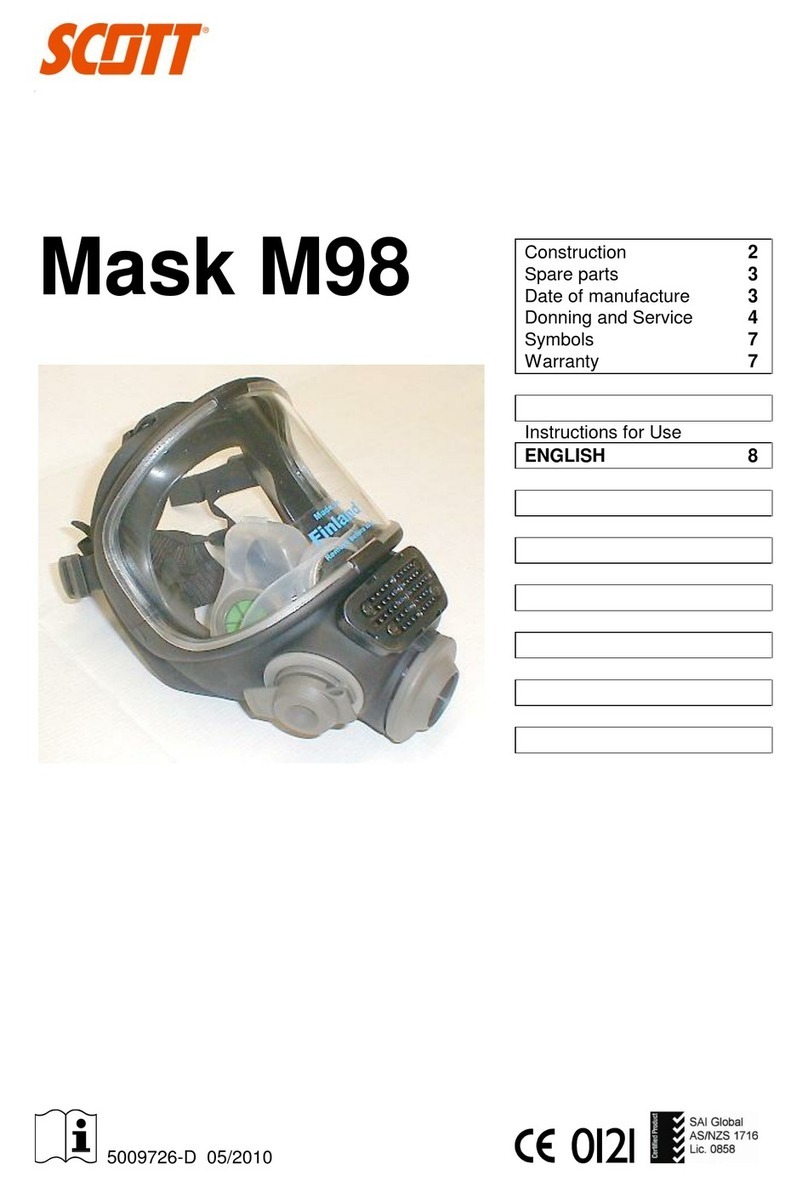

Full face mask ENGLISH

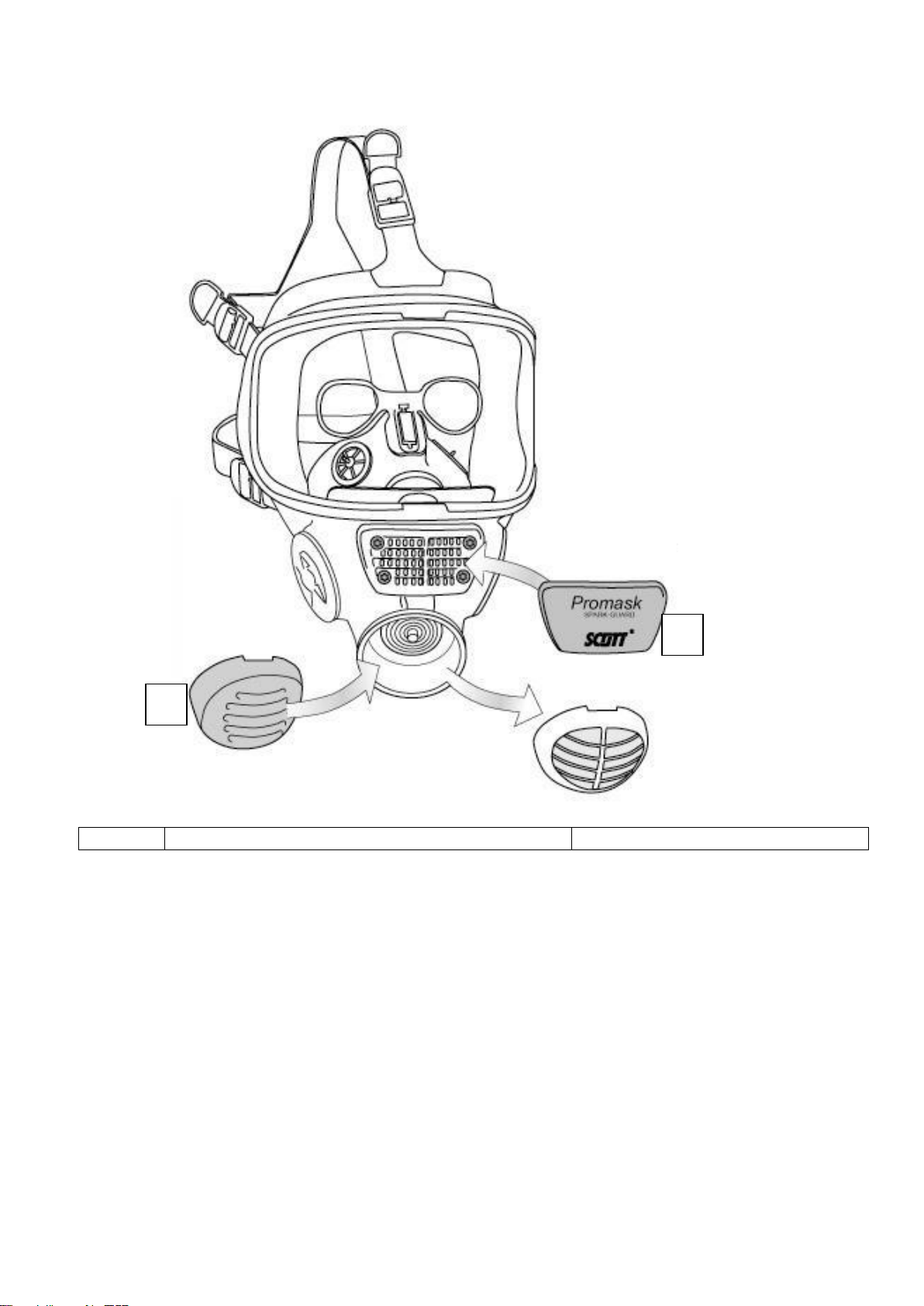

Promask

+ filter Pro2000

+ blower device Autoflow, Proflow

012681 Promask black

012670 Promask S (small) black

012882 Promask SIL yellow

Promask2

+ 2 x filter Pro2

012890 Promask2SIL grey

The Promask has been designed to conform with EN 136/12942 (Europe) and AS/NZS 1716:2003

(Australia/NZ). EC certified by BGIA (Berufsgenossenschaftliches Institut für Arbeitssicherheit), DE-53754

Sankt Augustin, Germany, ID: 0121. Licence 0858 by SAI Global, Australia.

1. General

The Promask is designed to protect the respiratory system and face against hazardous gases and

particles.

The filter is selected according to the type of hazard present.

Promask

oUse as filter mask together with a Pro2000 filter (gas, particle or combined filters). The filters are

thread filters conforming to the European standard EN 148-1.

oUse with a blower device, with the filters fitted to the blower device.

oMaterial: Mask made of butyl-EPDM (Procomp) or silicone. Inner mask made of TPE or silicone.

Promask2

oUse as filter mask together with Pro2filters (2 pcs, bayonet connection).

oMaterial silicone.

2. Limitations of use

2.1 The filtering device must not be used if the environment and contamination is unknown. In case of

doubt, isolating respirators (air supply) which function independently of the atmosphere must be

used.

2.2 The filtering device must not be used in confined spaces (e.g. cisterns, tanks) because of the risk of

oxygen deficiency or presence of heavy oxygen-displacing gases (e.g. carbon dioxide).

2.3 The filtering device may be used only if the oxygen content of the air is 18–23 vol.%.

2.4 Gas filters do not protect against particles. Similarly, particle filters do not provide protection against

gases or vapours. In case of doubt, use combined filters.

2.5 Normal filtering devices do not protect against certain gases such as CO (carbon monoxide), CO2

(carbon dioxide) and N2(nitrogen).

2.6 Particle filters are only allowed for single use if they are applied against radioactive agents or micro-

organisms (virus, bacteria, fungi and spores).

2.7 It is likely that adequate protection cannot be guaranteed if the user’s beard, hair, spectacle frames

or clothing intrude into the faceseal. With the Promask one can use special spectacles (see 012790

spectacle frame).

2.8 When a breathing protector is used in explosive atmospheres, please follow the instructions given

for such areas.

2.9 Gas filters shall be replaced when the user begins to sense odour, taste or irritation. Filters used

against detrimental gases that do not display any significant indications, require special regulations

for the duration of use and correct usage.

Particle filters must be replaced at the latest when breathing resistance becomes too high.

2.10 The weight of filter used with a full face mask shall not exceed 500 g.

The Promask is used with one filter only (the other opening on the mask is blocked by the

manufacturer).

The Promask2is used with Pro2filters. Always use two filters of the same type and class, always

replace both filters at the same time.

With a blower device

2.11 The blower must be running while using the respirator. If the blower turns off by accident, the

device ceases to function as a respirator, and carbon dioxide levels may instantly rise. This is

considered an exceptional situation.

2.12 At a very intense working pace, the pressure in the facepiece can change into negative pressure at

peak inhalation.

2.13 Protection levels may be reduced if wind speed exceeds 2 m/s.

2.14 Filters must not be fitted directly to the breathing hose.