4641

East

Ivy

S

treet,

Mesa,

AZ

85205

|

(480

)

256-

0017

|

[email protected] |

SCYNCE.AG

7

the science of yield

• THIS PRODUCT MUST BE INSTALLED IN

ACCORDANCE WITH THE APPLICABLE

INSTALLATION CODE BY A PERSON FAMILIAR

WITH THE CONSTRUCTION AND OPERATION OF

THE PRODUCT AND THE HAZARDS INVOLVED

ATTENTION

INSTALLING THE FIXTURE

INSTALLATION PREP

MOUNTING THE LIGHT FIXTURE

ELECTRICAL CONNECTION

CONTROLING THE LIGHT

1. Switch o main voltage

2. Refer to your light plan. Arrange boxed light

fixtures in specified mounting locations.

3. Remove the fixture from the packaging and

check contents.

4. Gather any additional tools and/or hardware that

may be required to mount the fixture.

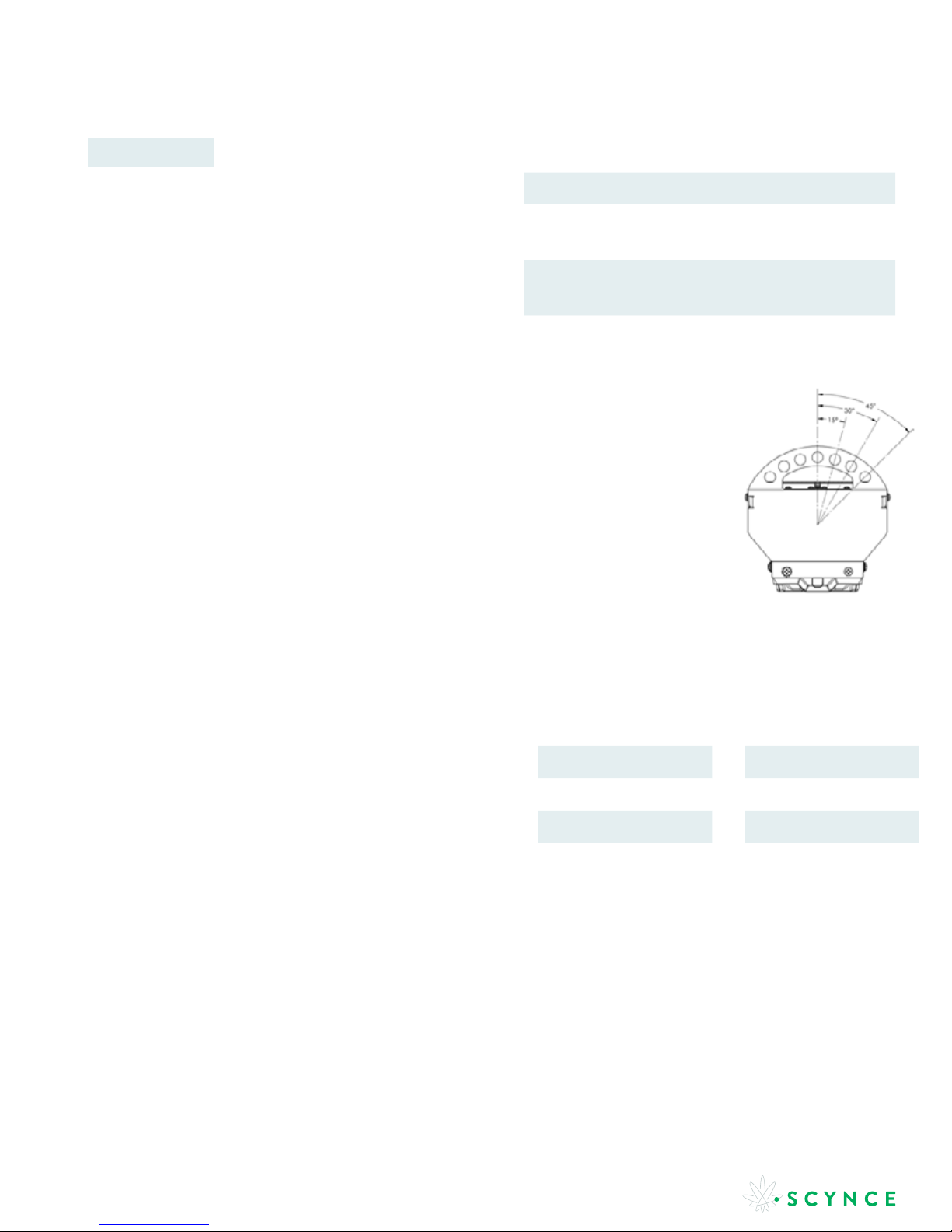

The Dragon XL 1200/LX 600 is designed to hung using the mounting brackets at either end

of the fixture’s cowling. There are four mounting hole options, each of which will aim the

fixture at a dierent angle. The optional aiming angles are; 0° 15°, 30°, and 45°.

See Figure 1 for additional details.

When mounting the Dragon XL1200 or XL600 fixtures in an array a minimum distance of 8

inches side to side and a minimum distance of 1 inch end to end must be maintained. When

mounting next to a ceiling or wall, movable partitions, and the like, insure a minimum distance

of 1.5 inches is between the fixture and the ceiling and 8 inches between the fixture and the

wall and other adjacent objects.

Dragon XL 1200/XL 600 is equipped with a 7ft power cord,

terminated with a standard wall pug (NEMA 5-15).

Simply plug the light in and you are ready to go.

Always ensure that fixtures are compliant with local building codes.

When routing the fixture power cord ensure that;

- The cord is not concealed or extended through a wall, floor,

ceiling, or other parts of the building structure.

- The cord is not located above a suspended ceiling or

dropped ceiling.

- The cord is not permanently axed to the building structure.

- The cord is routed so that it is not subject to strain and is

protected from physical damage.

- The cord is visible over its entire length.

Dragon XL 1200/XL 600 is equipped with four

independent channels of LEDs (White 2700K, White

4200K, White 6000K, and Red 600 nm). Each

channel can be independently dimmed from 0% to 100%.

Channel dimming can be adjusted on-demand using the

mobile app (See Mobile App Instructions for details) or

by setting up an embedded schedule in the light (See

Scheduling Instructions for details).

Figure 1: Fixture

mounting detail

To ensure safe operation of the lighting equipment it is

necessary to control the temperature of the room by

mechanical ventilation or cooling system to below the

maximum ambient operating temperature of 40ºC (104ºF).

SINGLE

PHASE CORD

TERMINATION

DOUBLE

PHASE CORD

TERMINATION

BLACK Line

WHITE Neutral

GREEN Ground

BLACK Line

WHITE Line

GREEN Ground