8 EB 9527-3 EN

Design and principle of operation

3 Design and principle of oper-

ation

Differential pressure meters are used to mea-

sure and indicate differential pressure as

well as derived measured variables for gases

and liquids.

Measurement tasks

Liquid level measurement in stationary pres-

sure vessels and in pressure vessels on trans-

portation vehicles, in particular for cryogen-

ic gases, such as argon, oxygen, and nitro-

gen.

−Differential pressure measurement be-

tween ow and return ow pipe

−Pressure drop measurement across valves

and lters

−Flow rate measurement according to the

differential pressure method

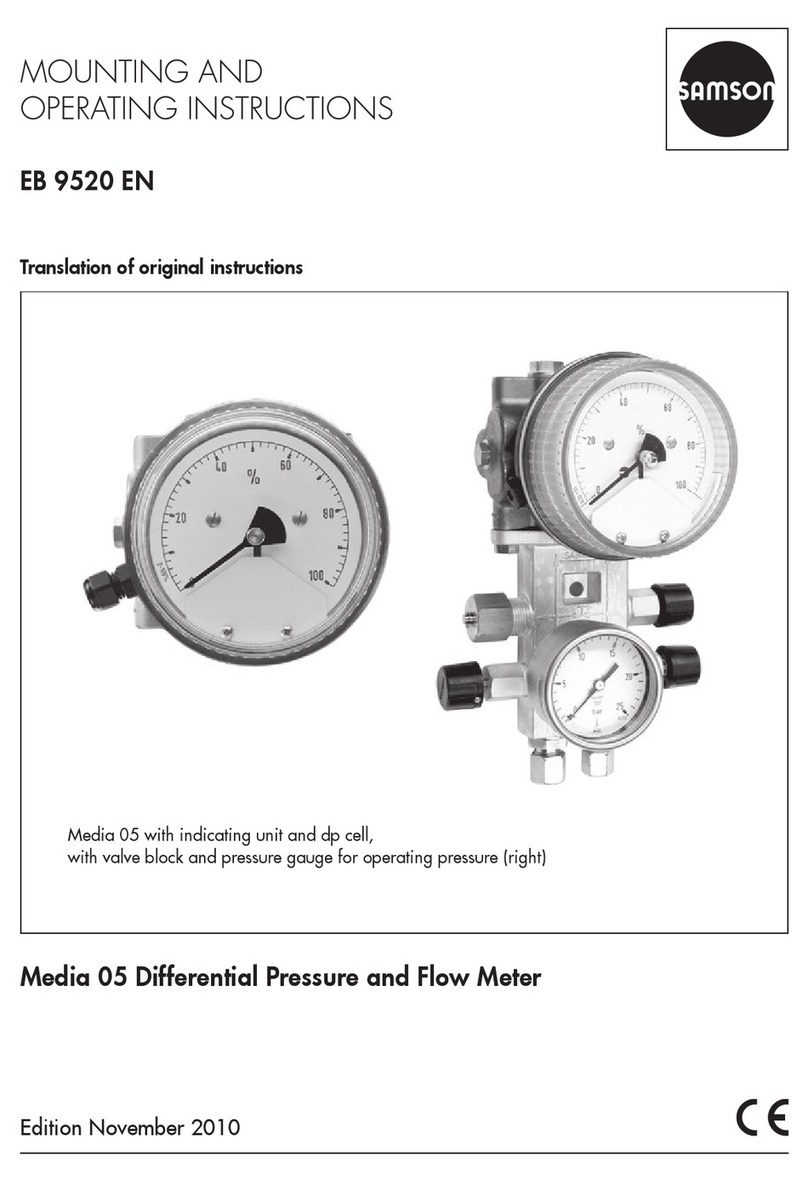

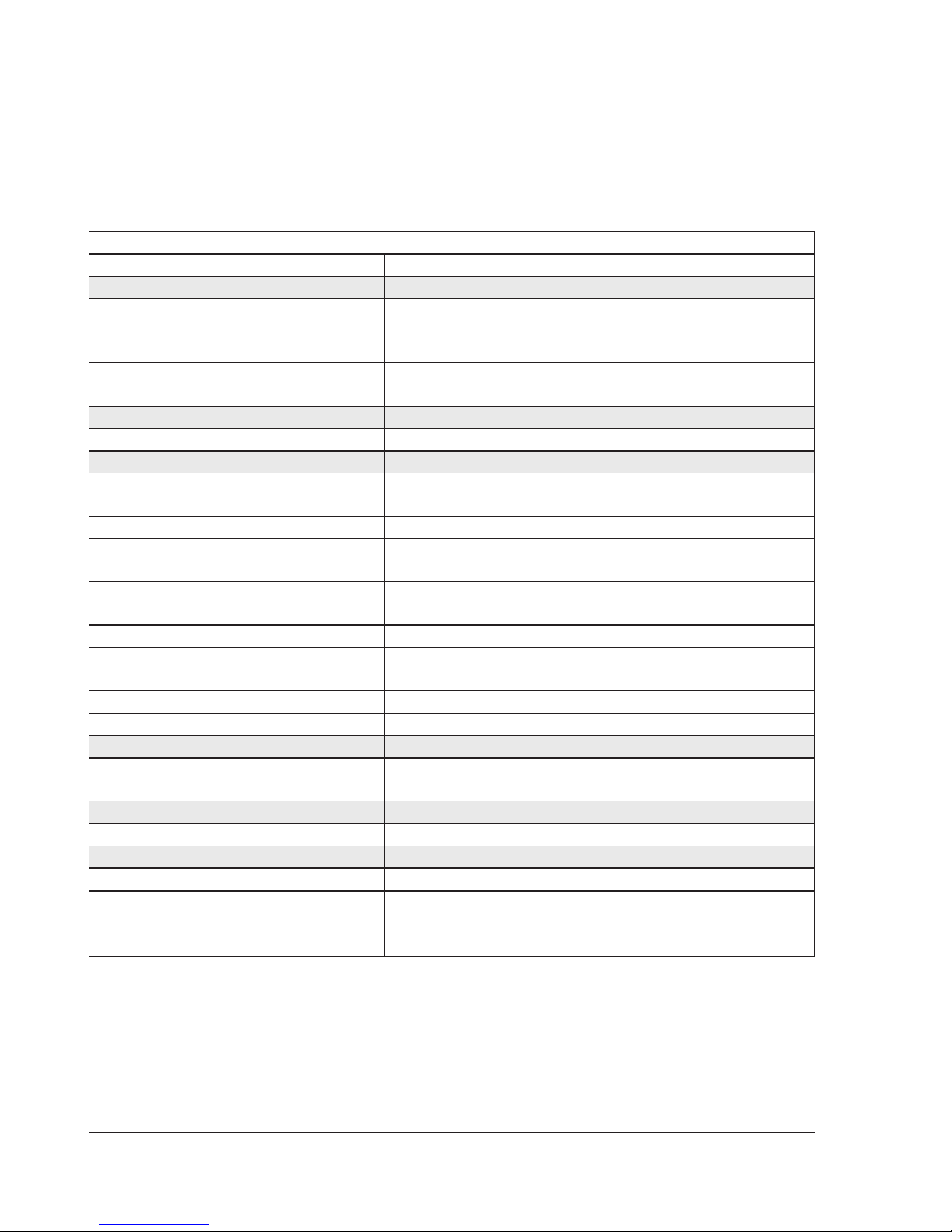

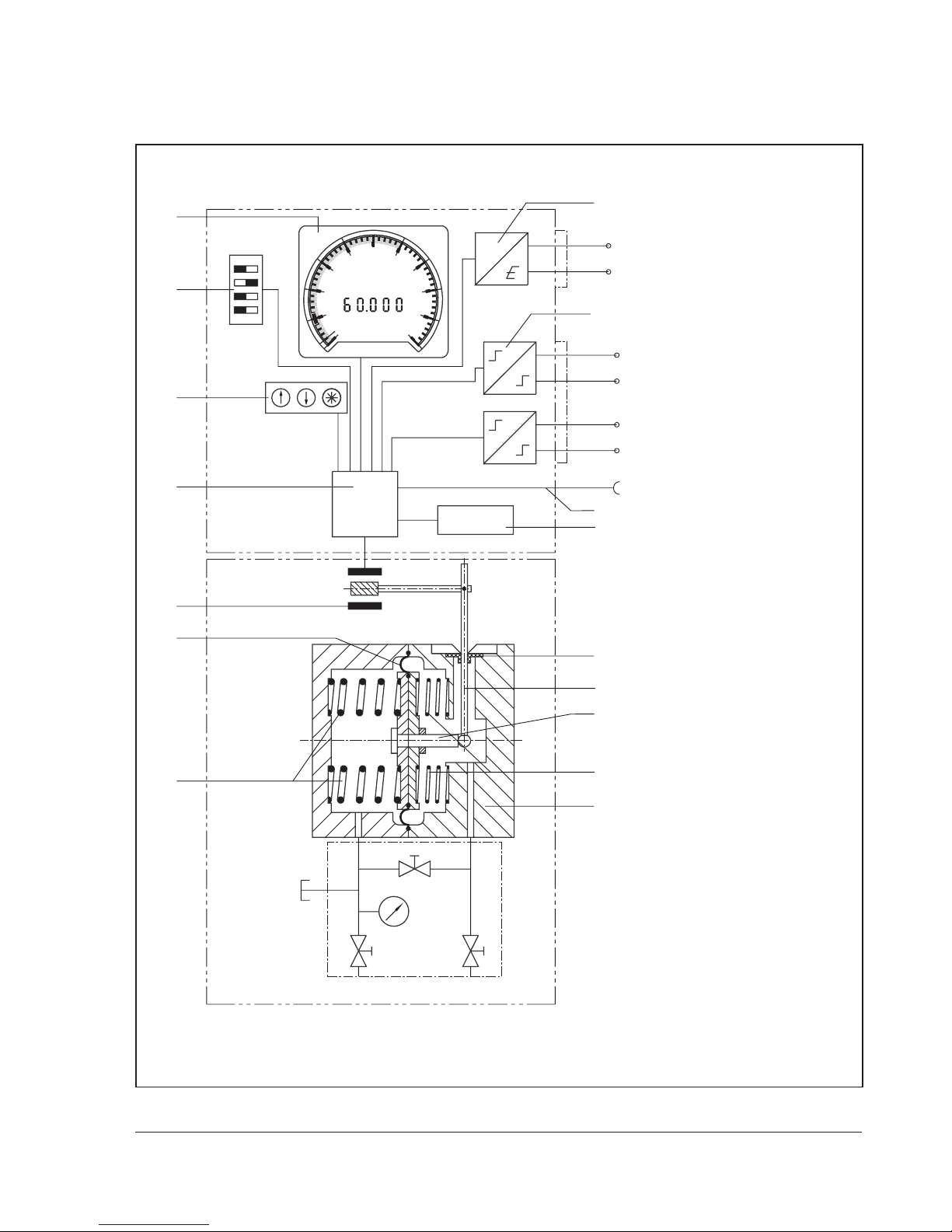

The device mainly consists of the dp cell with

measuring diaphragm, range springs sized

according to the measuring span as well as

the indicating unit with two-wire transmitter

(4 to 20mA output signal) and an LCD. The

power supply UB is 12 to 36VDC. Option-

ally, battery operation1) with 9VDC, with-

out 4 to 20mA output signal.

The differential pressure ∆p=p1 – p2creates

a force at the measuring diaphragm (1.1),

which is opposed by the range springs (1.2).

The movement of the measuring diaphragm

and lever (1.3), which is proportional to the

differential pressure, is transmitted by the

elastic disk (1.4) out of the pressure chamber

and converted into an electric signal by the

travel sensor (2).

Based on the evaluation of the data saved in

the FRAM (4), the electric signal is processed

by a microprocessor (3). It controls both the

LCD (7) and the D/A converter (9) for the

output signal, which is issued as a 4 to

20mA two-wire transmitter signal at con-

nector A.

The serial interface (10) allows the device to

be congured with the TROVIS-VIEW soft-

ware using a special memory pen or a cable

connection to a computer. The user-specic

data are saved in the memory (FRAM) (4).

Data backup is also possible. The data re-

main saved until they are overwritten again.

This allows operating data to be easily ex-

changed on site between Media 6 and the

memory pen, and vice versa. The memory

pen can be programmed on a computer us-

ing the TROVIS-VIEW software.

The operating data allow the differential

pressure to be converted into values propor-

tional to the tank capacity or ow rate 2) and

displayed or issued as a 4 to 20mA signal.

The DIP switches (6) are used to select four

saved gas types and different write protec-

tion functions for saved data.

Three operating keys (5) are used to adjust

different operating functions (zero and span

adjustment, lling limit during operation,

limit contacts, and test function settings etc.)

as well as set different operating states (load

or save operating values).

1) Operating mode: liquid level measurement

2) Counting pulse (Media 6 Z)