5.3. LOWERING THE LOAD.

p

p

p

WARNING! Ensue the load is central and stable on the jack saddle before attempting to lower.

SLOWLY depress the release pedal (fig.1. 020) to GENTLY lower the saddle to minimum height before attempting to transport the load.

QIMPORTANT: Speed of lowering is controlled by amount you depress the pedal. The more the pedal is depressed the more rapid the

saddle descent. Ensure the descent is slow and controlled to avoid the risk of sudden dropping.

5.4. TRANSPORTING THE LOAD.

p

p

p

WARNING! Ensure you have read, understood and apply Section 1 safety instructions.

5.4.1. Ensure the jack saddle is fully lowered, then secure the load by placing the support chains over the load, pull taut and engage with

hook on opposite side of the saddle. Tighten wing nut.

5.4.2. Transport the load over level and solid surface, preferably concrete, and ensure the floor is swept clean.

5.4.3. Be diligent in continually monitoring the load in transit. Keep all other persons at a safe distance.

s

s

s

DANGER! DO NOT use on tarmacadam, or any soft surface as jack may sink or topple. Serious or fatal injury may result.

s

s

s

DANGER! Should jack tip or lean for any reason STOP WHAT YOUR ARE DOING AND MOVE QUICKLY TO A SAFE DISTANCE.

DO NOT TRY TO HOLD OR STEADY JACK. Serious personal or fatal injury may result.

5.5. RE-INSTALLING A TRANSMISSION.

To transport, reposition beneath a vehicle, and raise a load up, reverse the procedures outlined above.

6. MAINTENANCE

IMPORTANT: Only fully qualified personnel should attempt maintenance or repair.

6.1. When the jack is not in use, the saddle must be in the lowest position to minimise ram and piston corrosion.

6.2. Lubricate moving parts with acid free oil, and grease the tilt mechanism. Wipe excessive oil and grease off and keep jack clean.

6.3. Check hydraulic oil regularly with the saddle in the lowest position.

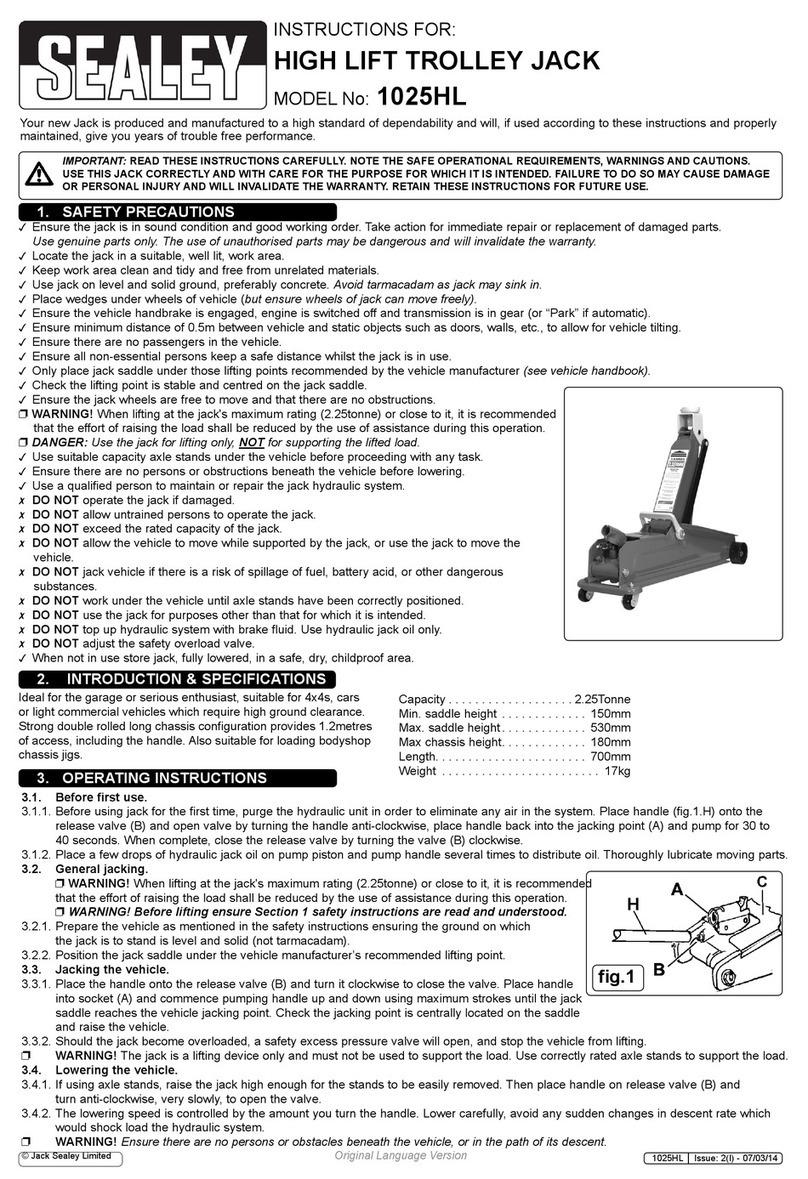

a) Remove air bleed screw (fig.1.017) and add oil via screw hole.

b)The hydraulic oil should be changed once a year. Contact your authorised dealer for information.

p

p

p

WARNING! Use only good quality jack oil, such as SEALEY HYDRAULIC JACK OIL. DO NOT use brake fluid as this will melt seals.

6.4. Before each use check for any visible damage to welds and ensure components are not damaged, broken, cracked, bent, malfunctioning,

distorted, worn, loose, leaking, dirty, noisy or missing (see Section 4). If any suspect item is found remove jack from service and take

necessary action to remedy the problem.

DO NOT use the jack if believed to have been subjected to abnormal load or shock. Inspect and take appropriate action.

6.5. Periodically check the pump piston and piston rod for signs of corrosion. Clean exposed areas with a clean oiled cloth.

IMPORTANT:NO RESPONSIBILITY IS ACCEPTED FOR INCORRECT USE OF THE MACHINE.

Hydraulic products are only repaired by local service agents. We have service/repair agents in all parts of the UK. DO NOT RETURN JACKS

TO US. Please telephone 01284 757500 to obtain address and phone number of your local agent. If jack is under guarantee please contact your dealer.

De-commissioning the Jack: Should the jack become completely unserviceable and require disposal, draw off the oil into an approved container

and dispose of the jack and the oil according to local regulations.

THE PROBLEM THE CAUSE THE SOLUTION

Jack will not lift

Jack will only lift halfway

Jack will not hold load

Poor lifting

Saddle tilt screw too tight

Jack will not lower

Release valve is open or no hydraulic oil

Defective suction valve or delivery valve

Hydraulic oil low, or excess of hydraulic oil

Defective valves, or defective piston packing

Defective plunger packing

Bolts and nuts may be bent or rusted.

Release valve blocked by foreign object

Close release valve, adjust oil level.

Contact authorised service agent.

Adjust oil level.

Contact authorised service agent.

Contact authorised service agent.

Check, clean, oil or replace items.

Clear any items from around pedal.

7. TROUBLESHOOTING

IMPORTANT! Although the following may identify a problem, in most cases the problem must be resolved by your authorised service agent.

Declaration of Conformity We, the sole importer into the UK, declare that the product listed here is in conformity with the following EEC standards and directives.

The construction file for this product is held by the Manufacturer and may be inspected on

request by contacting Jack Sealey Ltd.

For Jack Sealey Ltd. Sole importer into the UK of Sealey Quality Machinery.

Telescopic Transmission Jack Model 800GTA

98/37/EEC Machinery Directive (S.I. 1992/3073)

93/68/EEC CE Marking Directive

2nd August 1999

800GTA - 0016 - (1) - 150799

01284 757500

E-mail:

sales@sealey.co.uk

01284 703534

Sole UK Distributor,

Sealey Group,

Bury St. Edmunds, Suffolk.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of product. WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required

for any claim. INFORMATION: For a copy of our latest catalogue call us on 01284 757525 and leave your full name and address, including postcode.

Signed by Mark Sweetman