5.1. When the jack is not in use, the ram should be in its lowest position to minimise corrosion. Remove

the handle to deactivate jack.

5.2. Keep the jack clean and lubricate all moving parts with oil on a regular basis.

5.3. Before each use check for broken, cracked, bent, or loose parts, or any visible damage to ram,

pump, saddle, lifting arm, frame and all parts including nuts, bolts, pins and other fasteners. If any

suspect item is found remove jack from service and take necessary action to remedy the problem.

DO NOT use the jack if believed to have been subjected to abnormal load or shock load.

5.4. Check the pump piston and the ram periodically for signs of corrosion. Clean exposed areas with a

clean oiled cloth.

5.5. After one year the oil should be replaced in order to extend the life of the jack. Use hydraulic jack oil only.

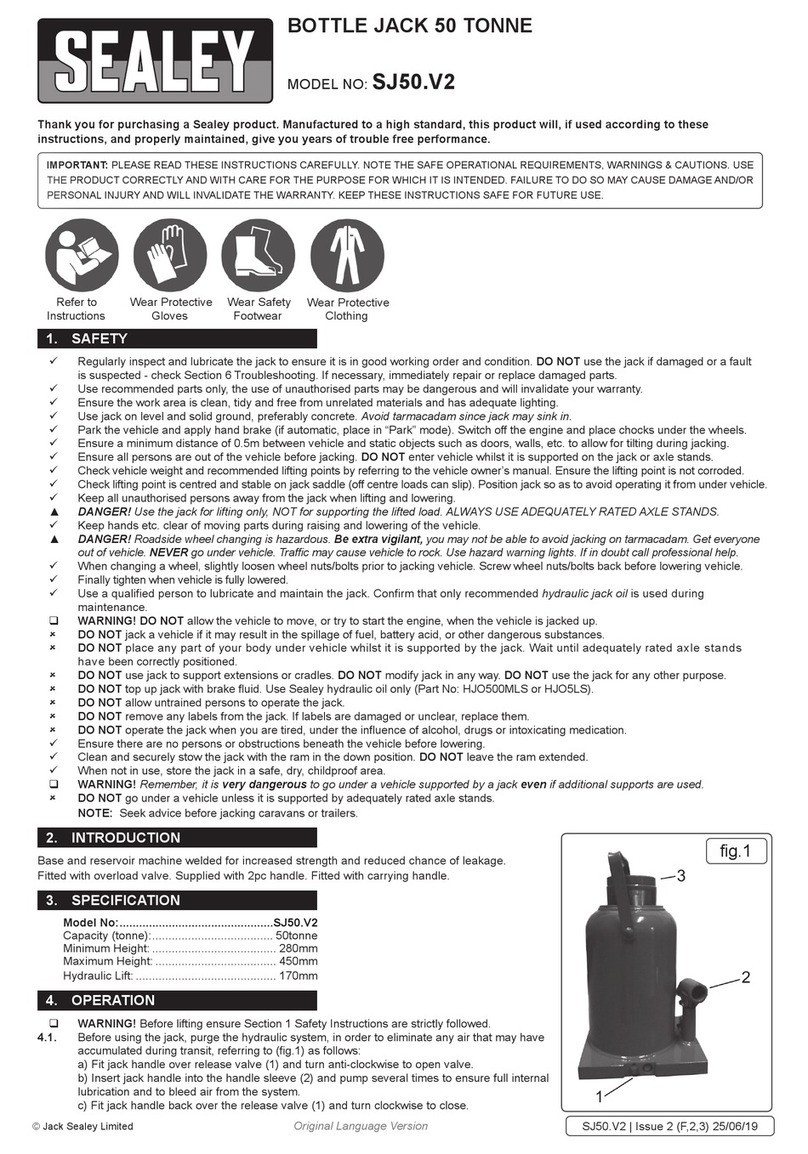

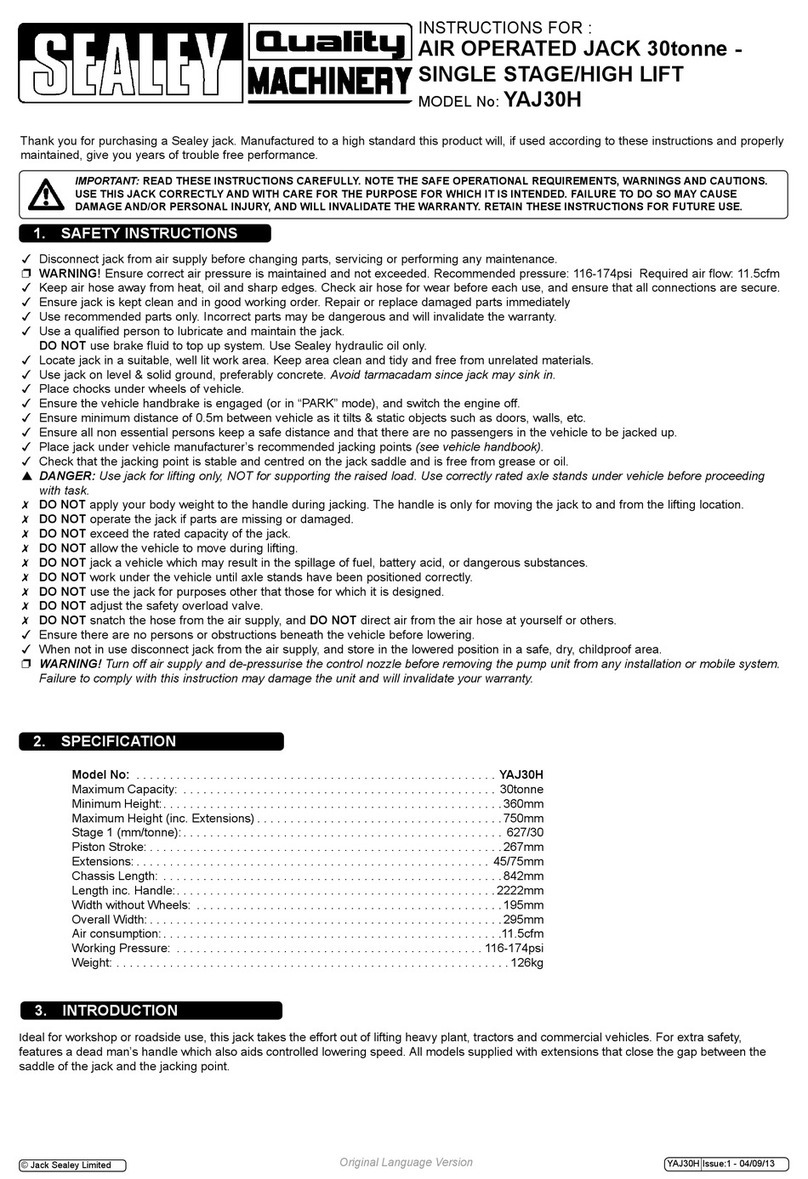

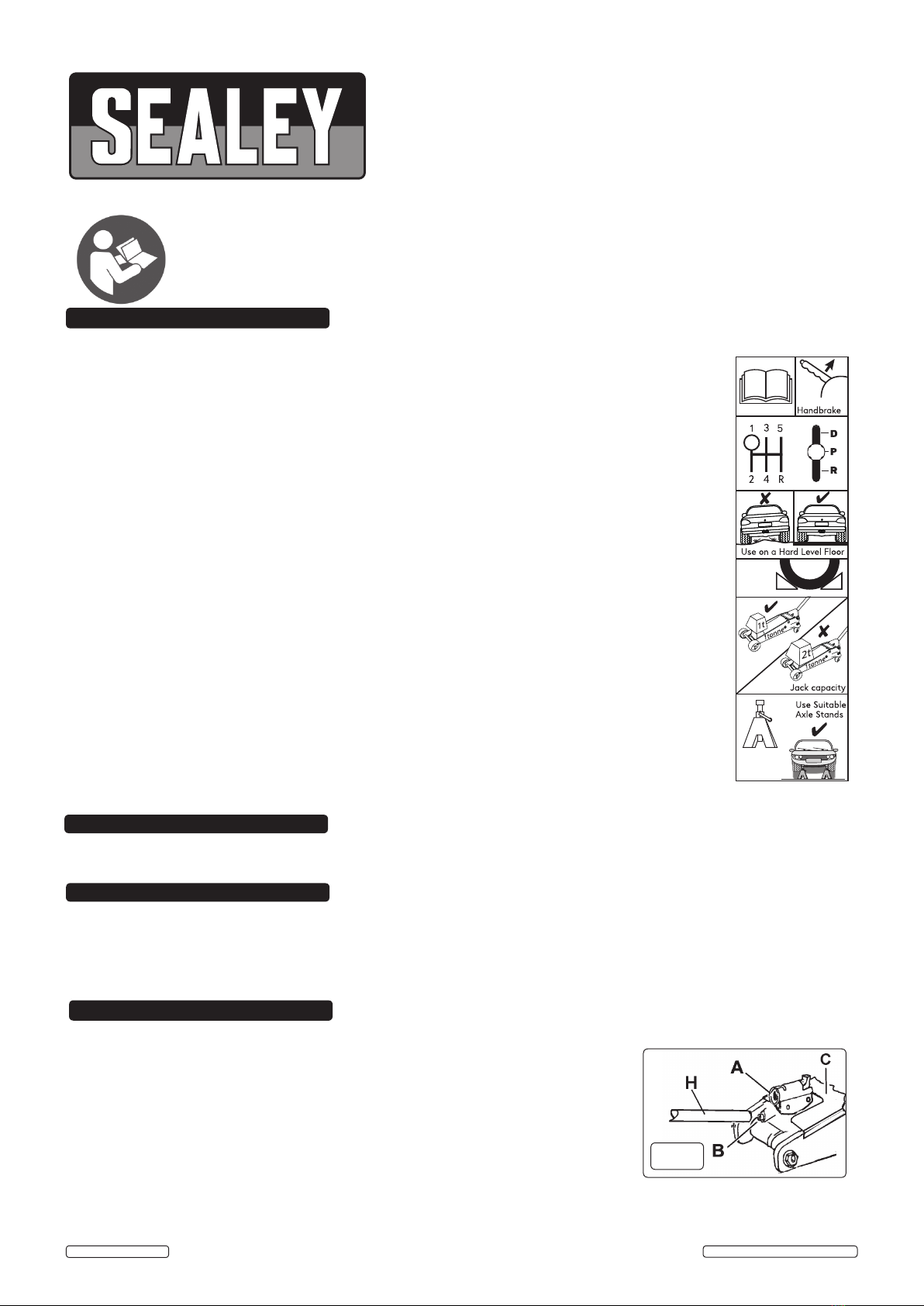

5.6. To check the oil level, fully lower the jack. Remove front cover plate (fig.1.C) and filler plug (fig.2.O).

The correct level is the bottom of the filler hole. If oil level is low, fill as required. Pump jack 5 or 6 times

to expel air. Pump jack up to full height and pour off excess oil before refitting plug. DO NOT touch the safety overload valve

(fig.2.V),

NOTE: Use a good quality jack oil, such as SEALEY HYDRAULIC JACK OIL.

WARNING: DO NOT use brake fluid, or any fluid other than hydraulic jack oil as this may cause serious damage to the jack

and will invalidate the warranty!

5.7. To drain the oil, remove the filler plug and raise front of jack. Make sure that no dirt is allowed to enter the hydraulic system.

IMPORTANT: NO RESPONSIBILITY IS ACCEPTED FOR INCORRECT USE OF THIS PRODUCT.

Hydraulic products are only repaired by local service agents. We have service/repair agents in all parts of the UK.

DO NOT return jacks to us. Please telephone us on 01284 757500 to obtain the address and ‘phone number of your local

agent. If jack is under guarantee contact your local Sealey dealer.

5. MAINTENANCE

5. TROUBLE SHOOTING

IMPORTANT: MAINTENANCE OR REPAIR OF HYDRAULIC SYSTEM MUST ONLY BE PERFORMED BY A COMPETENT PERSON.

fig.2

PROBLEM POSSIBLE CAUSE REMEDY

Jack will not lift the load 1) Overloaded

2) Oil level low

3) Release valve not correctly closed

4) Air in system

5) Piston rod not functioning

6) Packing worn or defective

1) Be sure to use jack with adequate capacity

2) Top up oil level

3) Check and close release valve

4) Open release valve and pump the handle a few times.

Close valve and re-try

5) Clean and replace oil

6) Replace packing

Jack does not lift high enough

or feels “spongy”

1) Oil level too high or too low

2) Worn seals

3) Air in system

4) Release valve not closed

1) Fill or remove excess oil

2) Return jack to local service agent

3) Open release valve and pump the handle a few times.

Close valve and re-try

4) Check and close release valve

Jack lifts poorly 1) Pump packing or valves malfunctioning

2) Oil is dirty

3) Air in the system

1) Replace packing and/or clean valves

2) Replace oil

3) Open release valve and pump the handle a few times.

Close valve and re-try

Jack lifts but will not hold load 1) Release valve partially open

2) Dirt on valve seats

3) Air in system

4) Faulty seals

5) Packing worn or defective

1) Check and close release valve

2) Lower jack, close release valve. Place foot on front wheel

and pull up lifting arm to it’s full height by hand.

Open the release valve to lower arm

3) Open release valve and pump the handle a few times.

Close valve and re-try

4) Replace packing or contact local service agent

5) Replace packing

Jack will not lower completely 1) Unit requires lubrication

2) Piston rod bent or damaged

3) Jack frame/link system distorted due to

overloading/poor positioning

4) Air in system

5) Release valve partially closed

6) Jack spring damaged or unhooked.

1) Oil all external moving parts

2) Replace rod or contact local service agent

3) Replace damaged parts or contact local service agent

4) Open release valve and pump the handle a few times.

Close valve and re-try

5) Check and fully open release valve

6) Replace spring or contact local service agent

Jack does not lower at all 1) Release valve closed 1) Check and fully open release valve

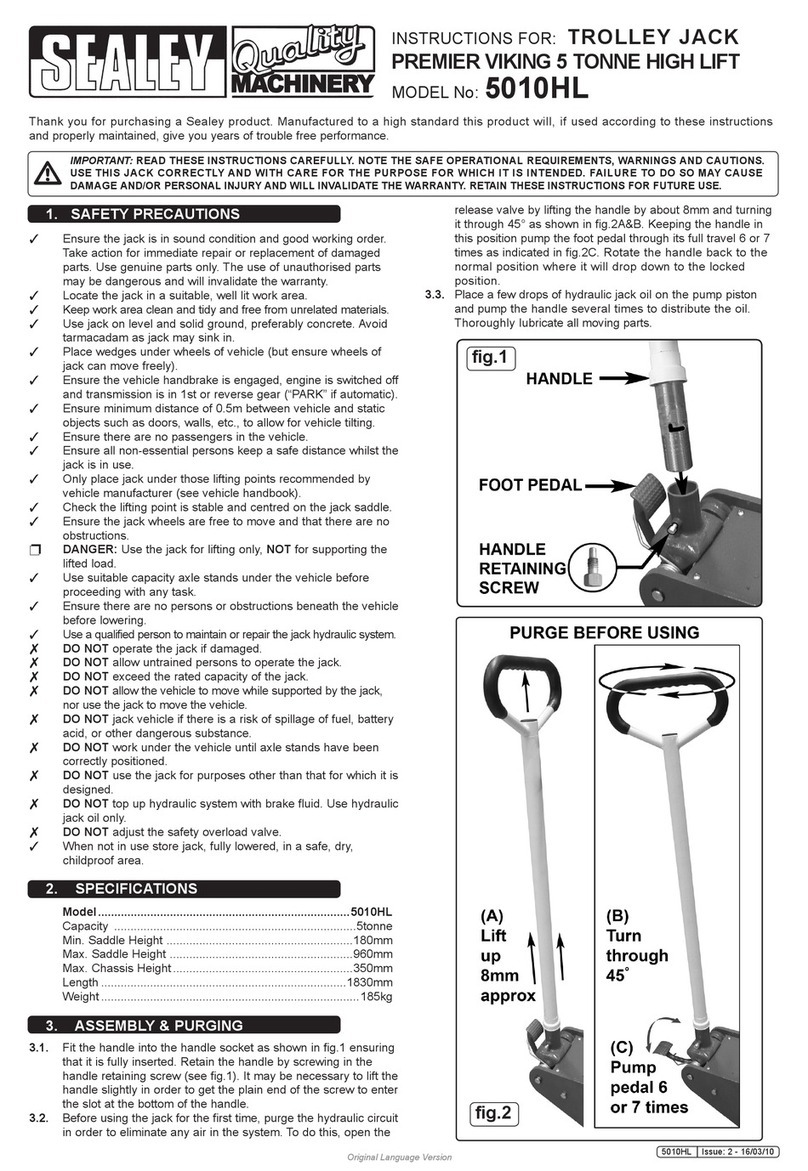

4.3. Jacking the vehicle.

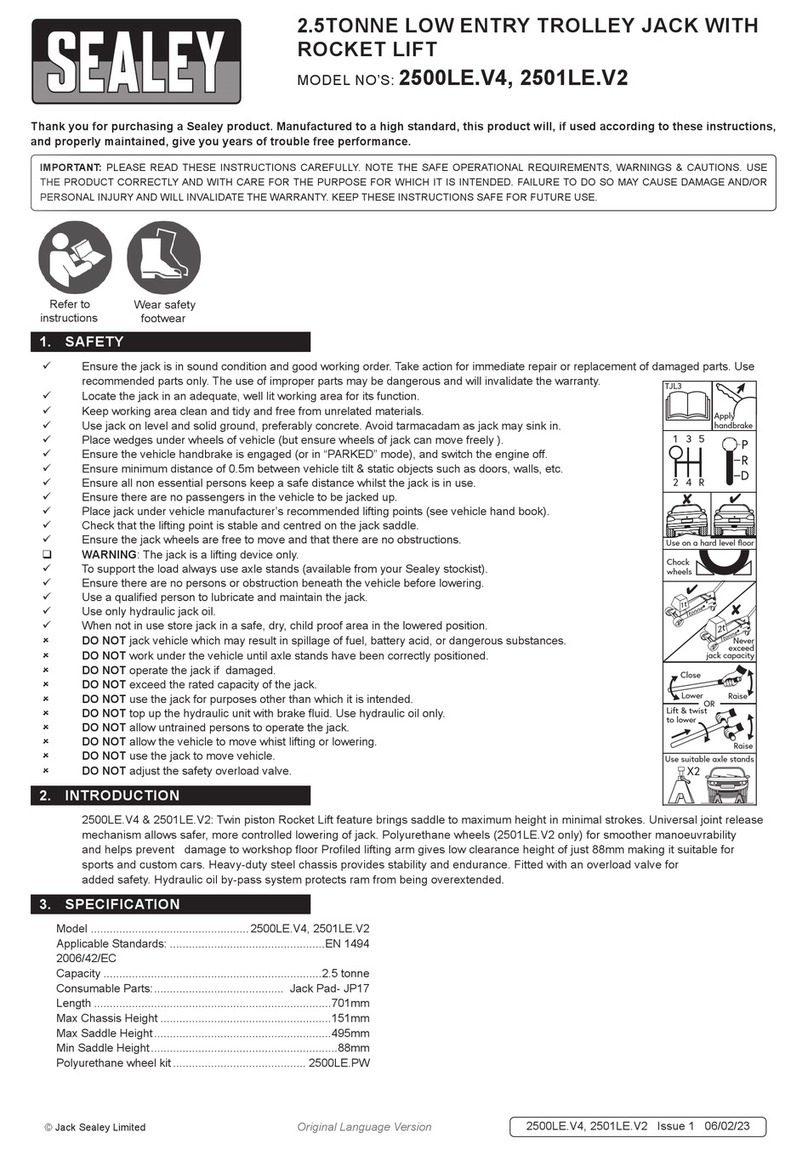

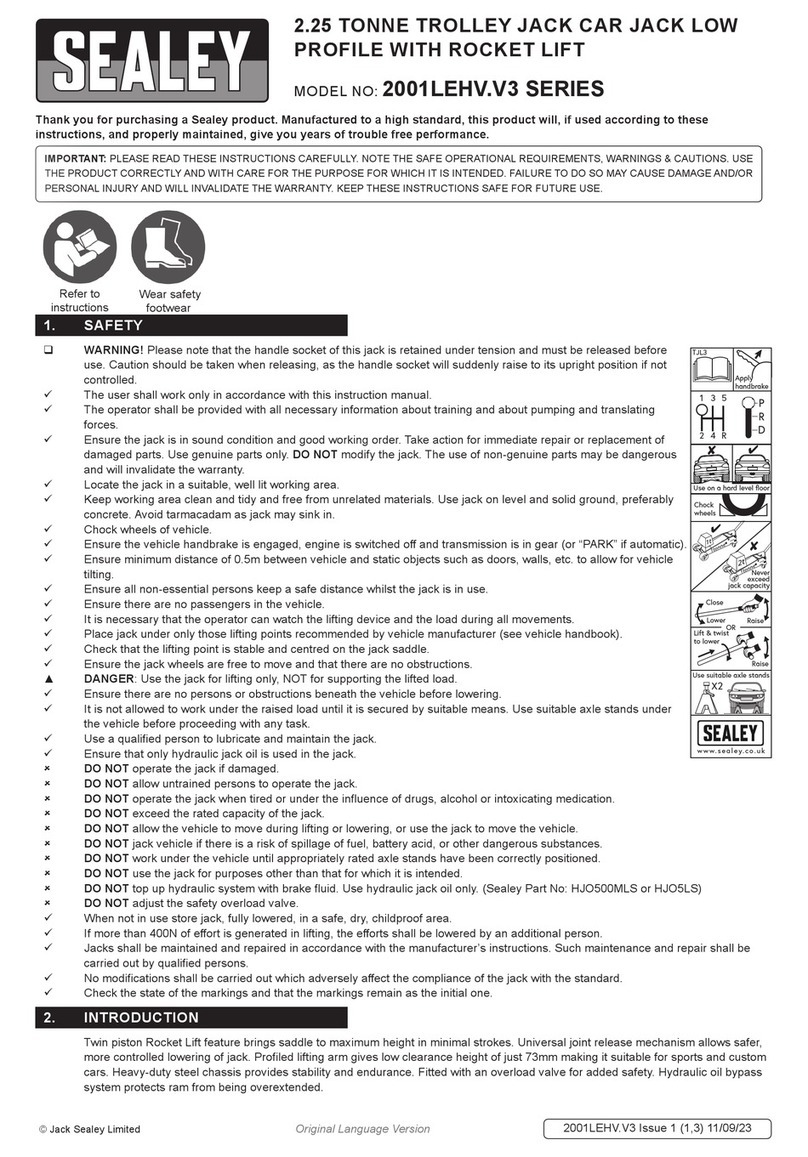

4.3.1. Place the handle onto the release valve (B) and turn it clockwise to close the valve. Place handle

into socket (A) and commence pumping handle up and down using maximum strokes until the jack saddle reaches the vehicle jacking

point. Check that the jacking point is centrally located on the saddle and raise the vehicle.

4.3.2. Should the jack become overloaded, a safety excess pressure valve will open, and stop the vehicle from lifting.

WARNING! The jack is a lifting device only and must not be used to support the load. Use correctly rated axle stands to support the

load.

4.4. Lowering the vehicle.

4.4.1. If using axle stands, raise the jack high enough for the stands to be easily removed. Then place handle on release valve (B) and

turn anti-clockwise, very slowly, to open the valve.

4.4.2. The lowering speed is controlled by the amount you turn the handle. Lower carefully, avoid any sudden changes in descent rate which

would shock load the hydraulic system.

WARNING! Ensure there are no persons or obstacles beneath the vehicle, or in the path of its descent.

Original Language Version 1153CX.HV Issue: 2(L)-30/06/17

©Jack Sealey Limited