Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and

properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

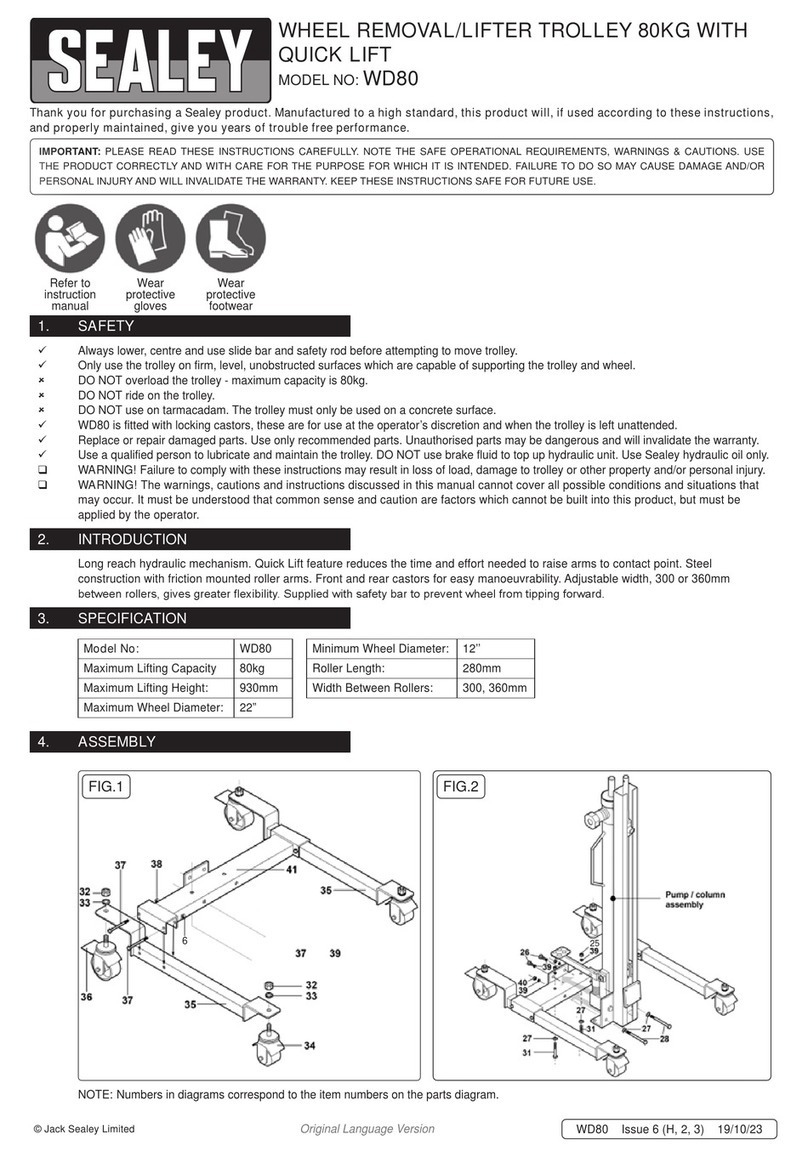

3.1 Content

3.1.1 The Vehicle Lift comprises:

Main lift assembly. Leading plate. Manual hydraulic pump assembly. Side extensions. Ramp extensions. Connecting bar. Motorcycle

Wheel Clamp. Bolts, nuts and washers.

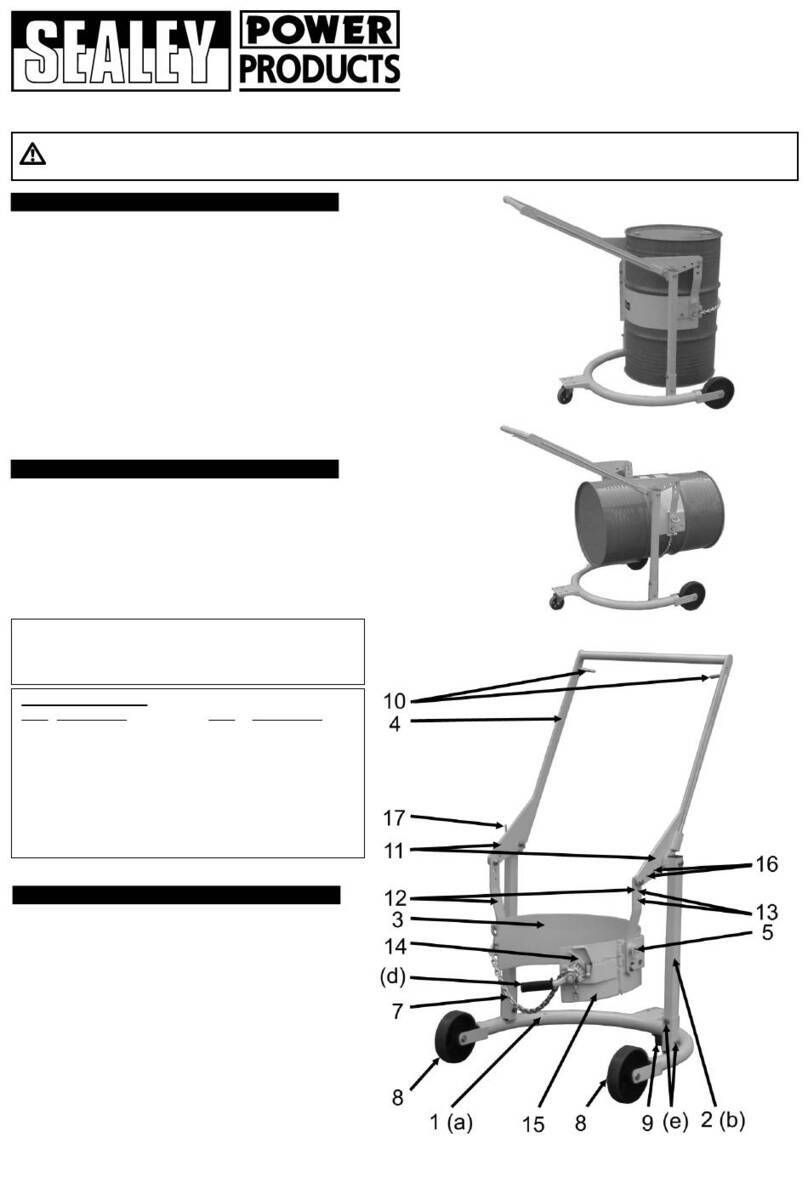

3.2 Assembly (Refer to Fig 3.)

3.2.1 Attach the sliding plate (8) to the platform using bolts, washers and nuts.

3.2.2 Connect the oil hose coupler (30) to the port on the hydraulic pump.

3.2.3 Attach the leading plate (9) to the end of the platform.

3.2.4 If necessary, when lifting vehicles, attach the two side extensions (51A) and (51) to the platform using the panel pipes (52) the

pins (49), washers (50) and nuts (54).

3.2.5 Attach the ramp extensions (53) and (53A) to the side extensions.

3.3 Motorcycle Wheel Clamp

3.3.1 Remove the clamp from the box and take the handle section (Fig.2A) and bolt to the top of the lift, through the pre-drilled holes, using

large bolts, nuts and washers.

3.3.2 Next take the moving jaw (Fig.2B) and bolt it to the handle section with the small bolts supplied.

3.3.3 Finally take the fixed jaw (Fig.2C) and bolt it to the top of the lift, through the remaining holes, using large bolts, nuts and washers.

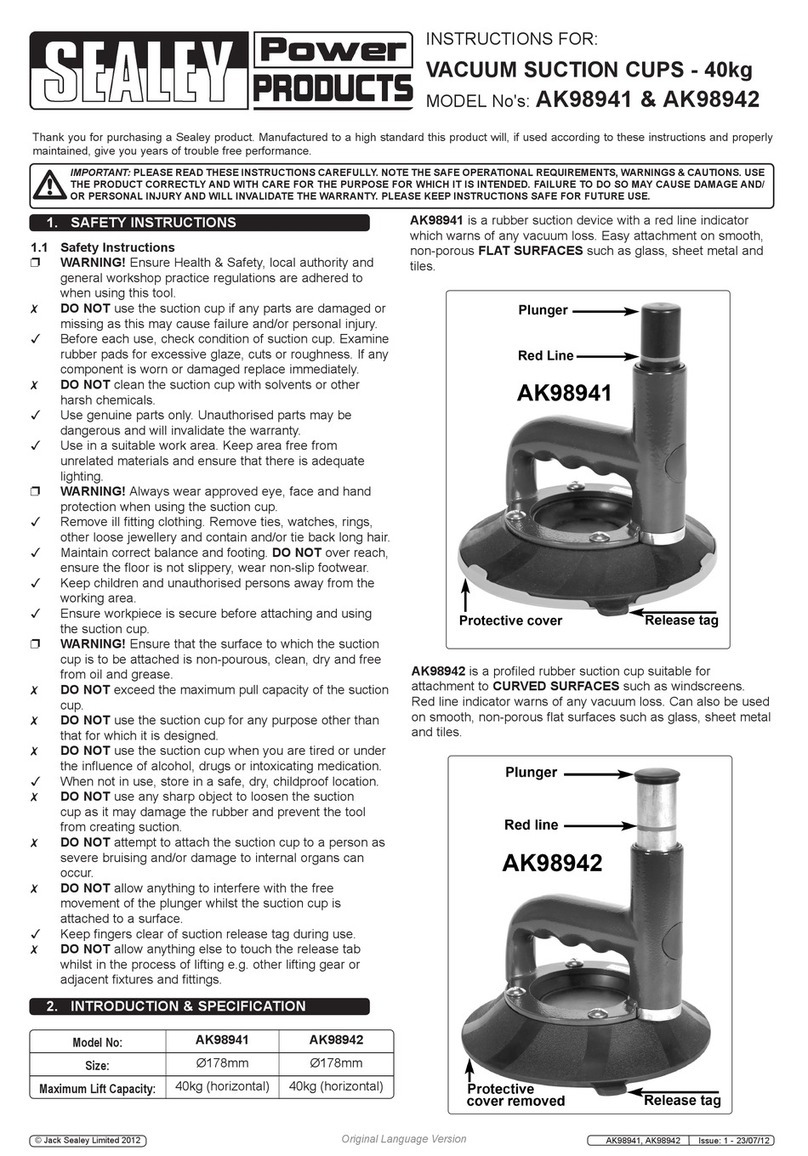

2. INTRODUCTION AND SPECIFICATION

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

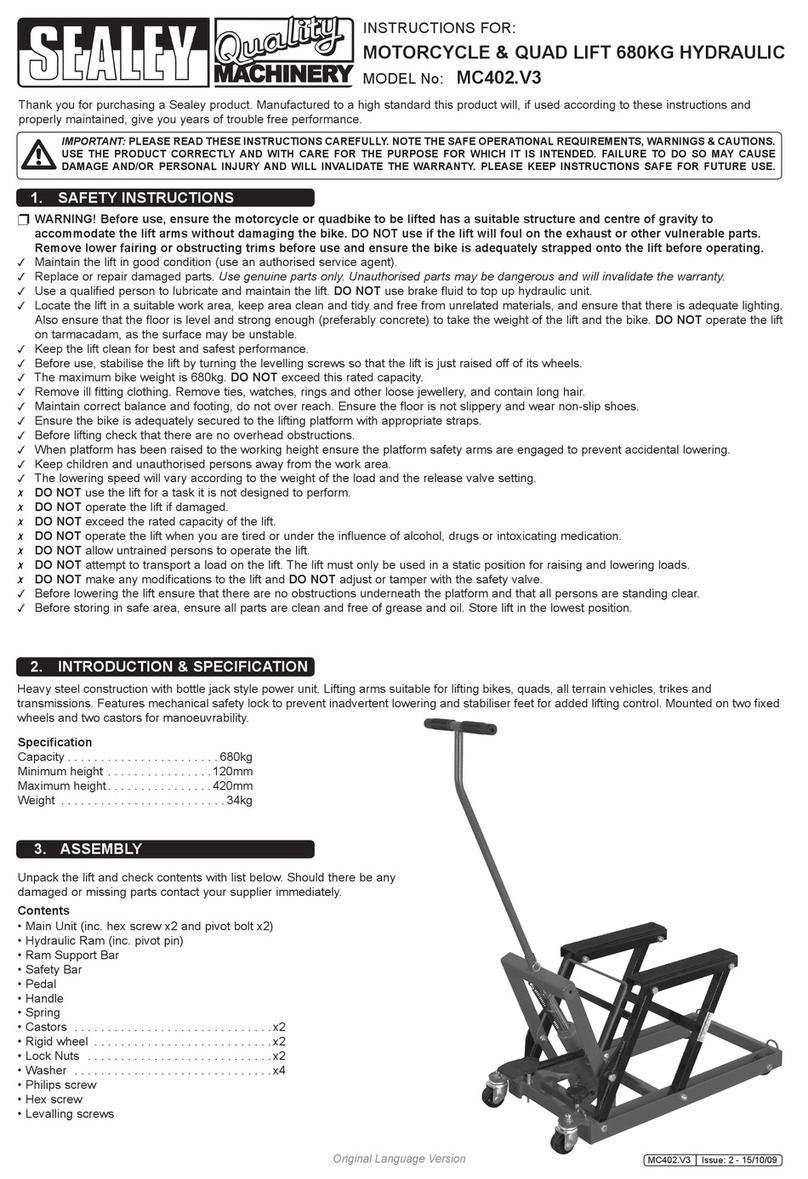

2.1 Introduction

All-steel construction with heavy-duty hydraulic ram. Supplied with

separate, foot operated, hydraulic pump and reservoir unit.

Features two additional side platforms for extra width. Ramp and

platform made with chequer plate surface to ease loading and

positioning of mini tractor/quad. Supplied with motorcycle front

wheel locking attachment, securing vehicle to provide easy

maintenance access. Fitted with safety lock to prevent accidental

lowering. Suitable for use with centre stand motorcycles or with

paddock stand.

2.2 Specification

Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MT680.V3

Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .680kg

Minimum Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190mm

Maximum Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..790mm

Standard Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 710mm

Maximum Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1220mm

Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2000mm

Table Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 710 x 2000mm

Side Extension . . . . . . . . . . . . . . . . . . . . . . . . . . 254 x 2000mm

WARNING! Ensure Health & Safety, local authority and general workshop practice regulations are adhered to when using this equipment.

Use a qualified person to lubricate and maintain the lift. DO NOT use brake fluid to top up hydraulic unit. Use Sealey hydraulic oil only.

Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

Keep the lift clean for best and safest performance.

Locate the lift in a suitable work area. Keep area clean and tidy and free from unrelated materials, and ensure that there is adequate lighting.

WARNING! Use lift on level and solid ground, preferably concrete. Avoid tarmacadam since the lift may sink into the surface.

Maintain correct balance and footing. Ensure that the floor is not slippery and wear non-slip shoes.

Keep children and non-essential persons away from the work area.

Never operate the lift with a load heavier than 680kg. Ensure the load is evenly distributed on the platform and secured if necessary.

Before lifting check that there are no overhead obstructions.

When raised, insert the safety bar to keep the platform from lowering.

When work is complete, check under the platform to ensure that there are no obstructions and that it is safe to lower the unit.

DO NOT operate the lift if any parts are damaged or missing as this may cause failure and/or possible personal injury.

DO NOT place any part of your body within or under the lift during use.

DO NOT operate the lift when you are tired or under the influence of alcohol, drugs or intoxicating medication.

DO NOT use the lift for any purpose other than that for which it is designed.

DO NOT allow untrained persons to operate the lift.

DO NOT make any modifications to the lift.

DO NOT expose the lift to excessive moisture or allow it to get wet.

Store lift in a dry, childproof environment when not in use.

Fig.1

Fig.2

3. CONTENT & ASSEMBLY

Original Language Version MT680.V3 Issue: 1 - 01/07/13

A

BC

© Jack Sealey Limited

INSTRUCTIONS FOR:

HYDRAULIC MINI TRACTOR/QUAD

MOTORCYCLE LIFT 680KG CAPACITY

MODEL No: MT680.V3