INSTRUCTIONS FOR:

LOAD SLING ADJUSTER WITH BALL

BEARINGS 680KG CAPACITY

Model No: LS501

1. SAFETY PRECAUTIONS 4. OPERATING INSTRUCTIONS

2. SAFE WORKING LOAD

5. MAINTENANCE & INSPECTION

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and properly maintained, give

you years of trouble free performance.

IMPORTANT: READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THE TOOL CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE

AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

3. INTRODUCTION & SPECIFICATION

©Jack Sealey Ltd Original Language Version LS501 Issue: 1 - 09/05/13

3 Ensure the load sling adjuster is in sound condition and good

working order. Take action for immediate repair or replacement of

damaged parts.

Use recommended parts only. The use of improper parts may be

dangerous and invalidate the warranty.

3 Ensure that the adjuster is capable of supporting the load that is to

be raised. Maximum capacity 680kg.

3 Keep the adjuster clean for best and safest performance.

3 Only use the adjuster in a suitable, well lit work area.

3 Keep the work area clean and free from unrelated materials.

3 Ensure that all non-essential persons keep at a safe distance,

whilst the adjuster is in use.

3 Ensure load sling(s) are fully engaged in their karabiners and that

the screw locks are securely closed.

3 Raise and lower the load in a smooth, controlled manner.

pDANGER! Use the adjuster for lifting only, NOT for supporting the

lifting load.

3 Use a qualied person to lubricate and maintain the adjuster.

7 DO NOT use the adjuster if damaged.

7 DO NOT allow untrained persons to operate the adjuster.

7 DO NOT exceed the rated capacity (safe working load) of the

adjuster.

7 DO NOT raise or lower the load with abrupt or jerky movements.

7 DO NOT attempt to lift a load if the load chains are kinked or

knotted.

7 DO NOT shock the load adjuster by allowing the attached load to

fall freely, even for very short distances.

7 DO NOT use the adjuster to drag the load across the oor. Always

position the load directly below the adjuster.

7 DO NOT allow anyone to stand, or pass, beneath the raised load.

7 DO NOT use the adjuster for purposes other than that for which it

was intended.

3 Store adjuster in a dry, childproof area when not in use.

LS 501

Safe Working Load = 680kg

Handles and levels heavy, off centre loads quickly and easily. Ball

bearing handle allows for a smooth and easy adjustment. Three

adjustment holes accomodate different sized engines. Ideal for car,

van truck and marine engines. If used with cranes of capacity 680kg or

more, the load must be restricted to a 680kg maximum. Supplied with

4 x 275mm chains and 4 x ‘L’ shaped brackets with additional karabiner

style screw links.

Model No: .................LS501

Sling Span: ................340mm

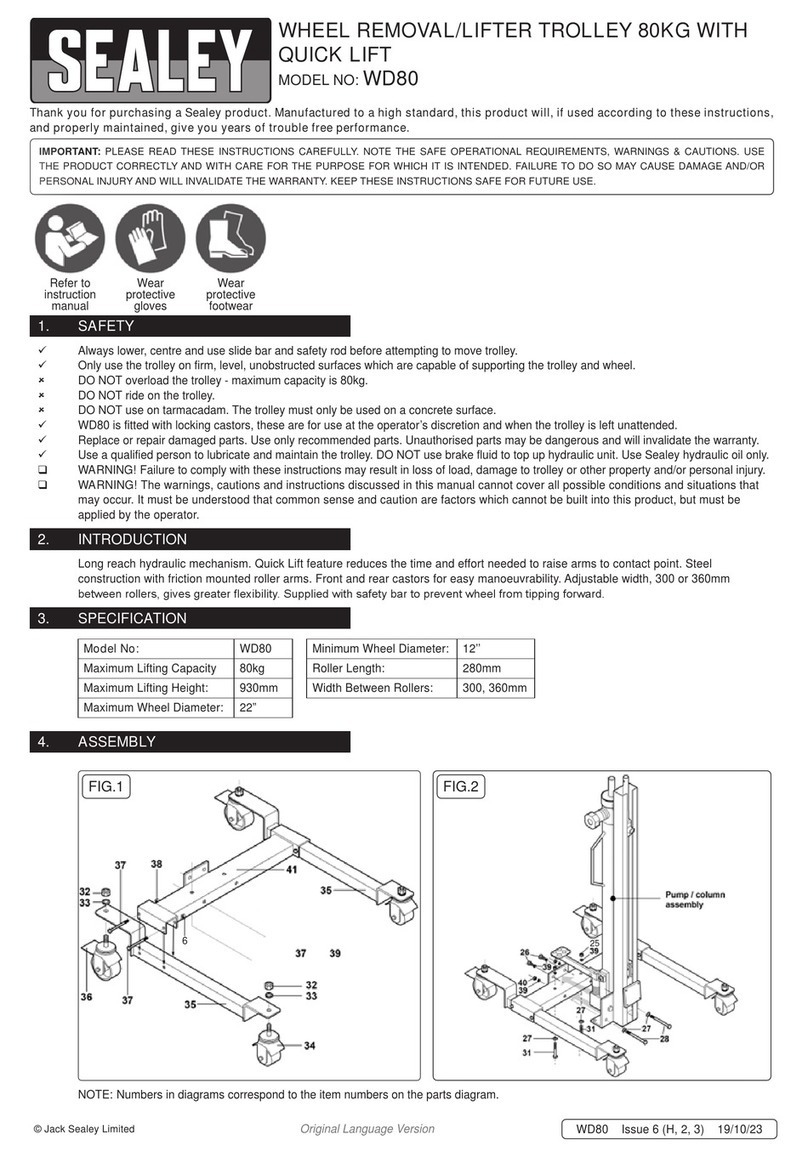

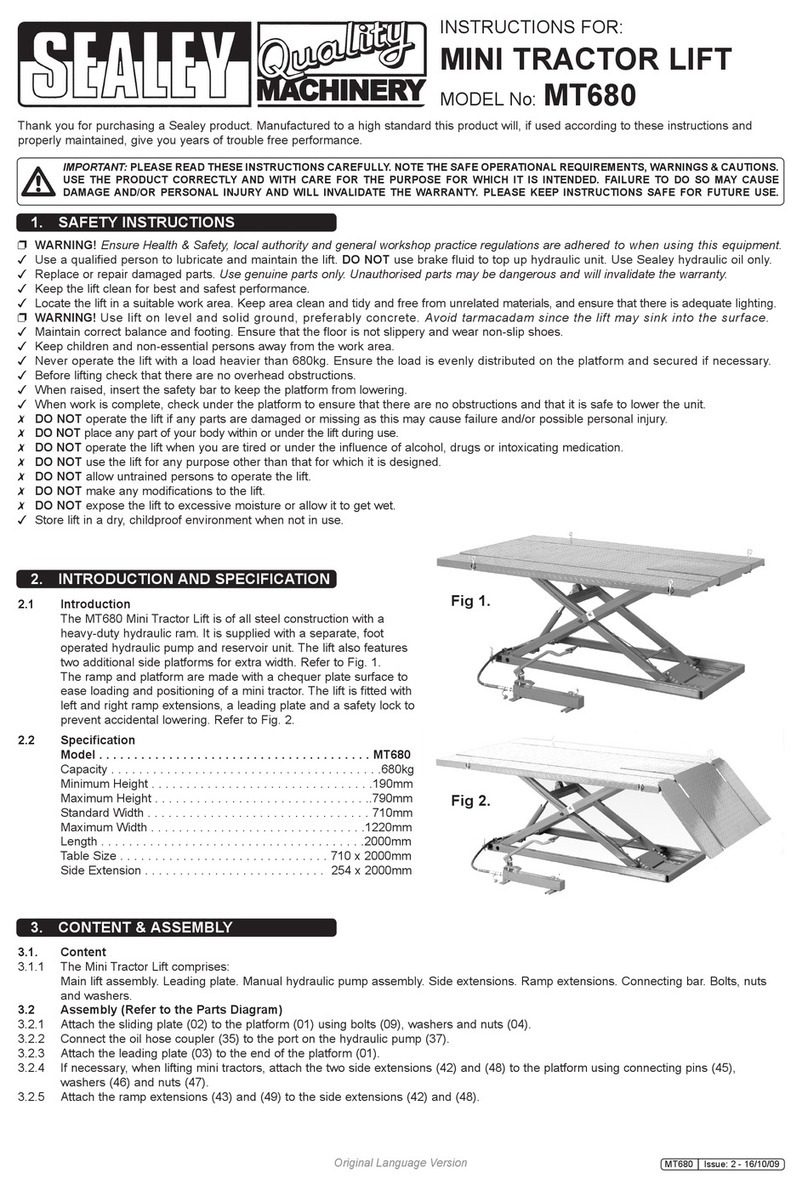

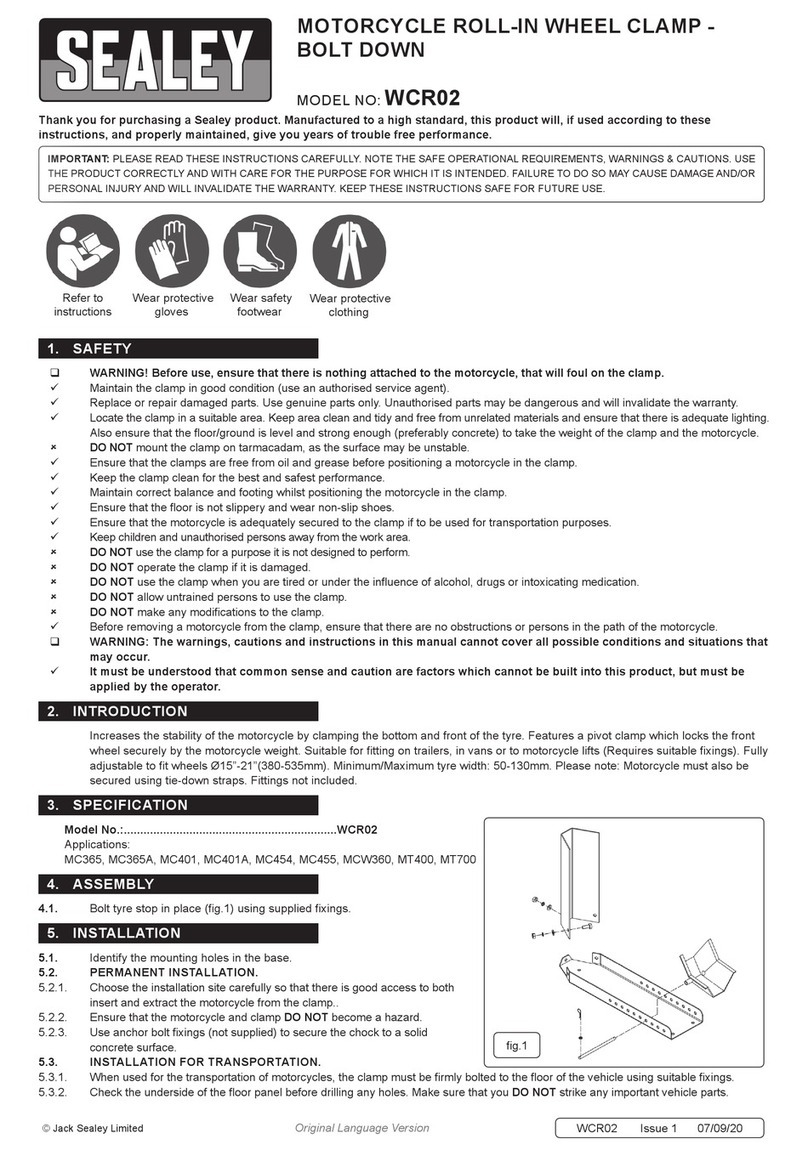

Refer to g.1

IMPORTANT: Before using the load sling adjuster ensure that you

have read and understood the safety instructions in Section 1.

4.1 Ensure that the load sling adjuster is suspended from a lifting

system in which all components are capable of supporting the

load to be lifted plus the load sling adjuster.

4.2 Conrm that the load does not exceed the safe working load of

the adjuster.

4.3 Position the carriage (A) at the centre of the beam (B) and

suspend the adjuster, via the carriage, from the hook or

shackle of the lifting device.

4.4 Ensure that the slings/chains/ropes around the load are

adequate and in good condition and that the load is directly

below the adjuster.

4.5 Attach slings/chains/ropes to adjuster load brackets (C).

4.6 Start to raise load and check whether the adjuster beam

remains level. If it does not, lower the load and adjust the

carriage towards the end of the beam which was low. Repeat

this check and adjustment until the beam lifts horizontally.

NOTE: DO NOT attempt to reposition the carriage when the

adjuster is under load.

Refer to g.1

NOTE: Only fully qualied personnel should attempt maintenance or

repair.

5.1 Keep the load sling adjuster clean and regularly lubricate the

threaded rod (D).

5.2 Carry out a visual inspection every time the adjuster is used.

p WARNING! The load chains and brackets are made from

special alloy steels and precisely heat treated. DO NOT

weld or re-heat treat.

5.3 Depending on the frequency of use and local conditions the

adjuster will eventually show signs of wear at which point it

should be replaced. Overloading or incorrect hooking may

distort the brackets, if this occurs replace immediately.