p WARNING! Ensure that you read, understand and apply the safety and operational instructions before connecting the meter. Only when you are sure that

you understand the procedures is it safe to proceed with testing.

p WARNING! Risk of electrocution. High voltage circuits both AC and DC are very dangerous and should be measured with great care.

Operating temperature range 0OC to 40OC.

Remember to turn on meter before use and to turn it off when measurement is completed.

NOTE: IF OL appears in the display during a measurement, the value exceeds the range you have selected. Change to a higher rating.

NOTE: On some low AC and DC ranges, with the test leads not connected to a device, the reading may show a random fluctuating reading. This is normal

and is caused by the high input sensitivity. The reading will stabilise and give a proper measurement when connected to a circuit.

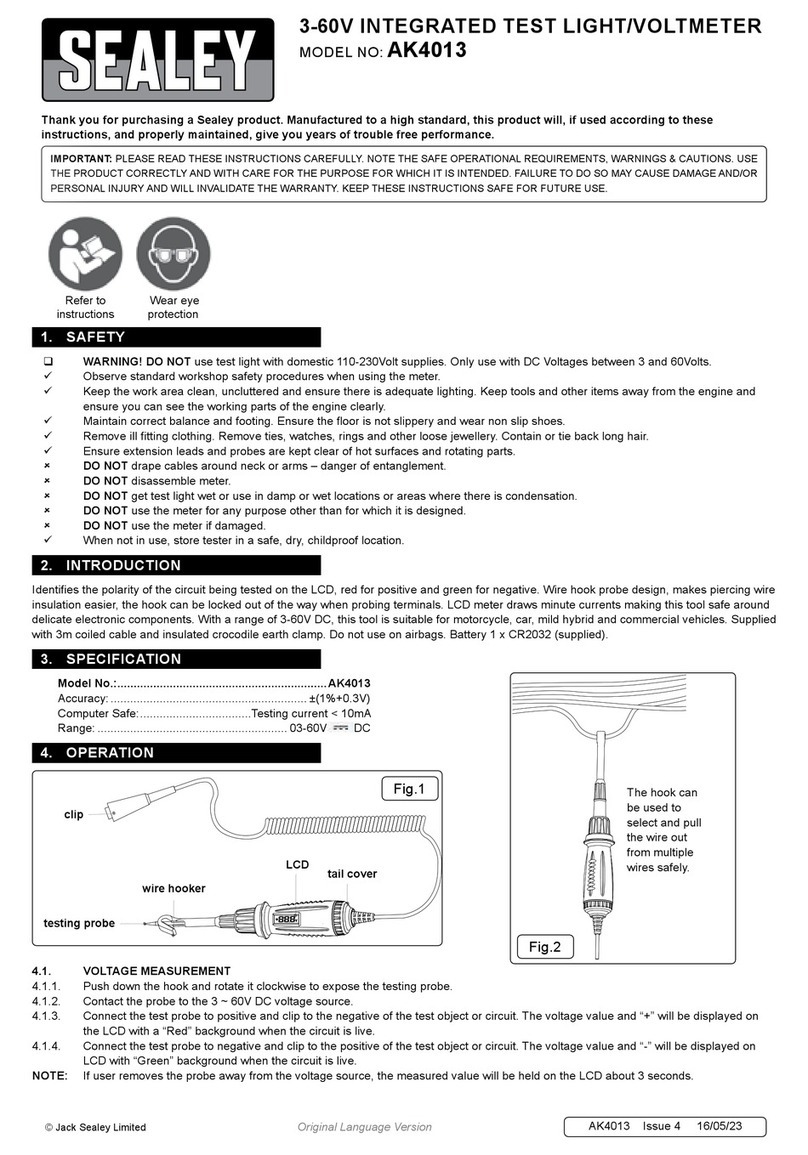

4.1. Mode Button (fig.1.11)

4.1.1. To select AC/DC voltages, AC/DC current, Resistance, Diode, Continuity and Capacitance check.

4.2. Range Button (fig.1.7.).

NOTE: When the meter is first turned on, it automatically selects the best range for the measurements being made and is generally the best setting for most

measurements. For measurements situations requiring that a range be manually selected, perform the following.

4.2.1. Press the Range button. The AUTO display indicator will turn off.

4.2.2. Press the range button to step through the available ranges until you select the range you want.

4.2.3. Press the range button for two seconds to exit the manual ranging mode and return to auto ranging.

4.3. Data Hold, Backlight Button (fig.1.9. & fig.1.10.).

4.3.1. The data hold function allows the meter to freeze a measurement for later reference.

4.3.2. Press the data hold button to freeze the reading in the display. The indicator hold will appear in the display.

4.3.3. Press the data hold button to return to normal operation.

4.3.4. Press and hold the backlight button to switch on the display backlight.

4.3.5. The backlight will automatically turn off after approx 10 seconds.

4.4. Relative Button (fig.1.8.).

4.4.1. The relative measurement feature allows you to make measurements relative to a stored reference value. A reference voltage, current etc can be stored

and measurements made in comparison to that value. The displayed value is the difference between the reference value and the measured value.

4.4.2 Perform any measurement as described in the operating instructions.

4.4.3. Press the relative button to store the reading in the display and the REL indicator will appear in the display.

4.4.4. The display will now indicate the difference between the stored value and the measured value.

4.4.5. Press the relative button to return to normal operation.

4.5. Hz/% Duty Button (fig.1.6.)

4.5.1 Press the Hz/% duty button to choose frequency or Duty Cycle in the range of frequency when measuring voltage or current.

4.5.2. Press the Hz/% duty button to return to measurement of voltage or current.

4.6. AC or DC Voltage Measurements

4.6.1. Insert the black test lead into the negative COM jack and the red test lead into the positive V jack.

4.6.2. Turn the rotary switch to the VDC/AC position.

4.6.3. Press the MODE button to select ac or dc voltage.

4.6.4. Touch the test probes to the circuit under test and read the voltage display.

Note: Pressing the Hz button (fig1.6.) while in the voltage function will switch the display to frequency or duty cycle.

4.7. AC or DC Current Measurements

p WARNING! Do Not make current measurements on the 10A scale for longer than 30 seconds in every 15 minutes. Exceeding 30 seconds may

cause damage to the meter and test leads

4.7.1. Insert the black test lead into the into the negative COM jack and the red test lead into the:

a) Positive uA/mA jack for currents to 400mA (fig.1.3.).

b) Positive 10A jack for currents to 20A (fig.1.5.).

4.7.2. Turn the rotary switch to the uA, mA or A position.

4.7.3. Press the mode button to select AC or DC current.

4.7.4. Touch the test probes in series with the circuit under test and read the current on the display.

4.8. Resistance, Diode, Continuity or Capacitance Measurements

p WARNING! To avoid electric shock, disconnect power to unit under test and discharge all capacitors before taking any resistance or

capacitance measurements.

4.8.1. Insert the black test lead into the negative COM jack and the red test lead into the positive Ω CAP jack.

4.8.2. Turn the rotary switch to the Ω CAP position.

4.8.3. Press the Mode button (fig. 1.11.) to select Ω or or or CAP.

4.8.4. Connect the test probes to the two ends of the Resistance, Diode, Continuity, Capacitance or circuit to be measured.

4.8.5. Read the measured value from the display.

4.8.6. When on continuity range a beeping will be heard if the resistance is lower than 150Ω.

4.8.7. When measuring the forward voltage across a good diode 0.4V or 0.7V will be indicated and the reverse voltage will indicate OL (same as on open

condition). For a short circuit diode, a value of 0mV will be displayed.

p WARNING! When checking in-circuit capacitance, be sure to disconnect the power supply from the circuit and that the capacitors are fully

discharged. The range control mode in capacitance measurement is auto-ranging.

4.9. Frequency or Duty Cycle measurements

4.9.1. Insert the black test lead into the negative COM jack and the red test lead into the positive Hz jack.

4.9.2. Turn the rotary switch to the Hz %DUTY position.

4.9.3. Press the Hz % button (fig.1.6.) to select Hz or %.

4.9.4. Touch the test probes to the circuit under test and read the frequency or duty cycle on the display.

4.10. Temperature Measurements

4.10.1. Insert the type K thermocouple plug into the negative COM jack and the positive jack ensuring the + symbol on the plug is inserted into the positive +

jack and the negative symbol on the plug is inserted into the negative COM jack.

4.10.2. Turn the rotary switch to the select °C or °F.

4.10.3. Read the temperature on the display.

TA201 - 1 - 220404

4. OPERATION